Preparation method of high performance heat-dissipating coating for tablet personal computer

A tablet computer and heat-dissipating coating technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor heat dissipation effect and poor heat dissipation function of coatings, achieve uniform dispersion, improve heat dissipation effect, and reduce interface thermal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

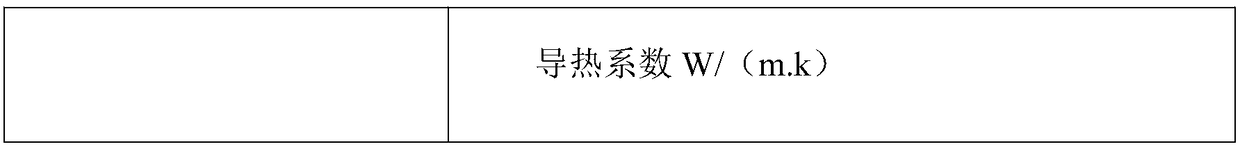

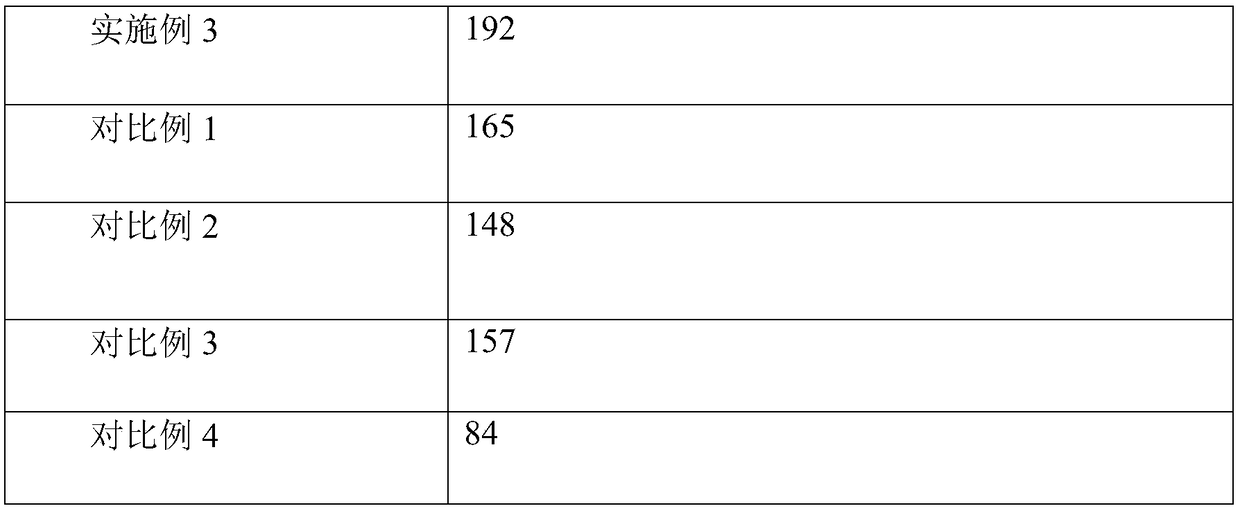

Embodiment 1

[0025] A method for preparing a high-performance heat-dissipating coating for a tablet computer of the present embodiment comprises the following steps:

[0026] Step 1: Add water-based polyurethane resin and hydroxyacrylic resin to the reaction kettle, the reaction temperature is 115°C, and the reaction time is 25 minutes, then add mixed rock powder, modified filler, microsphere emulsion, and finally add nano-titanium dioxide and silane The coupling agent KH550, the stirring speed is 125r / min, and the stirring time is 25min to obtain the mixture A;

[0027] In step 2, the mixture A, graphene, barium stearate, n-butanol, ultraviolet absorber, and catalytic promoter obtained in step 1 are added to the high-speed mixer in sequence, the stirring speed is 95r / min, and the stirring time is 35min, to obtain The high-performance heat-dissipating coating for a tablet computer of the present invention.

[0028] The hydroxyl acrylic resin in this embodiment is a mixture of low hydroxyl...

Embodiment 2

[0036] A method for preparing a high-performance heat-dissipating coating for a tablet computer of the present embodiment comprises the following steps:

[0037] Step 1: Add water-based polyurethane resin and hydroxyacrylic resin to the reaction kettle, the reaction temperature is 125°C, and the reaction time is 35 minutes, then add mixed rock powder, modified filler, microsphere emulsion, and finally add nano-titanium dioxide and silane The coupling agent KH550, the stirring speed is 135r / min, and the stirring time is 35min to obtain the mixture A;

[0038] In step 2, the obtained mixture A, graphene, barium stearate, n-butanol, ultraviolet absorber, and catalytic promoter in step 1 are added to the high-speed mixer successively, the stirring speed is 105r / min, and the stirring time is 45min, to obtain final product The high-performance heat-dissipating coating for a tablet computer of the present invention.

[0039] The hydroxyl acrylic resin in this embodiment is a mixture...

Embodiment 3

[0047] A method for preparing a high-performance heat-dissipating coating for a tablet computer of the present embodiment comprises the following steps:

[0048] Step 1: Add water-based polyurethane resin and hydroxyacrylic resin to the reaction kettle, the reaction temperature is 120°C, and the reaction time is 30 minutes, then add mixed rock powder, modified filler, microsphere emulsion, and finally add nano-titanium dioxide and silane The coupling agent KH550, the stirring speed is 130r / min, and the stirring time is 30min to obtain the mixture A;

[0049] In step 2, the mixture A, graphene, barium stearate, n-butanol, ultraviolet absorber, and catalytic promoter obtained in step 1 are added to the high-speed mixer successively, the stirring speed is 100r / min, and the stirring time is 40min, to obtain The high-performance heat-dissipating coating for a tablet computer of the present invention.

[0050] The hydroxyl acrylic resin in this embodiment is a mixture of low hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com