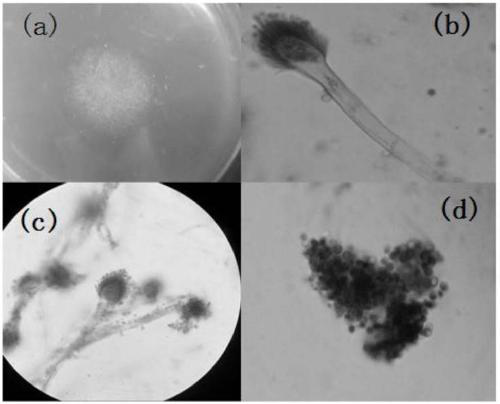

Sartorya Vuill W-10 with high cellulase production, and fermentation method and application thereof

A cellulase and Aspergillus technology, which is applied in the field of fermentation production of cellulase, can solve problems such as affecting the economic benefits of enterprises and increasing production costs, and achieve the effects of being beneficial to commercial application and implementation, increasing production, and improving economic benefits of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

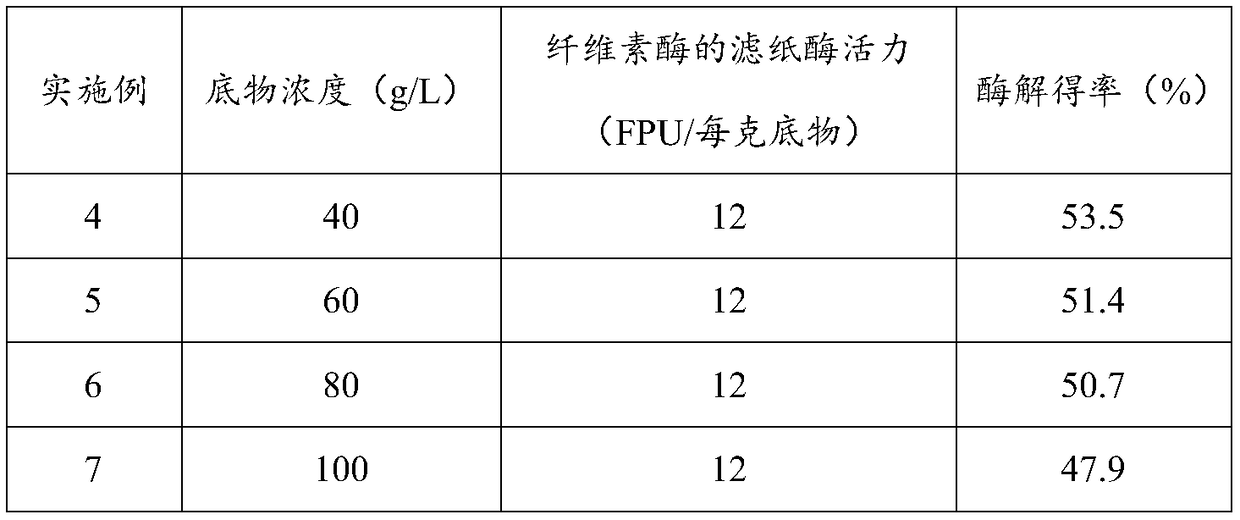

Examples

Embodiment 1

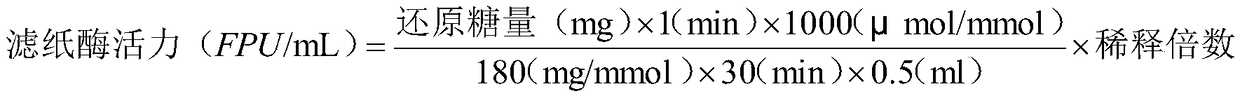

[0044] The specific preparation process of cellulase prepared by Aspergillus mycelium (Sartorya sp.Vuill W-10) is as follows:

[0045] (1) Preparation of culture medium: Preparing according to potassium nitrate 4g, lactose 4g, urea 0.2g, dipotassium hydrogen phosphate 1.5g, Mandel's nutrient solution 3ml, bran 6g, magnesium sulfate 0.5g, calcium chloride 0.3g, sodium hydroxide The treated straw powder was prepared at a ratio of 30g to obtain a medium, and the volume was adjusted to 1000mL with deionized water, and the pH value of the medium was adjusted to 3 with 1mol / L hydrochloric acid; then, according to the bottled volume of 43mL / 250mL, the prepared The culture medium is divided into the fermentation vessel;

[0046] (2) Inoculation of Aspergillus miliflora seed liquid: according to 10% of the volume of the culture medium, inoculate the Aspergillus miliflora seed liquid into a fermentation container filled with culture medium;

[0047] (3) Preparation of cellulase: fermen...

Embodiment 2

[0050] The specific preparation process of cellulase prepared by Aspergillus mycelium (Sartorya sp.Vuill W-10) is as follows:

[0051] (1) Preparing the culture medium: 4g of potassium nitrate, 4g of lactose, 0.2g of urea, 1.5g of dipotassium hydrogen phosphate, 6ml of Mandel's nutrient solution, 12g of bran, 0.5g of magnesium sulfate, 0.3g of calcium chloride, sodium hydroxide The treated straw powder was prepared at a ratio of 30g to obtain a medium, and the volume was adjusted to 1000mL with deionized water, and the pH value of the medium was adjusted to 2.5 with 1mol / L hydrochloric acid; then, according to the bottling volume of 60mL / 250mL, the The culture medium is divided into the fermentation vessel;

[0052] (2) Inoculation of Aspergillus miliformis seed liquid: according to 8% of the medium volume, inoculate the Aspergillus militicum seed liquid in a fermentation vessel filled with medium;

[0053] (3) Preparation of cellulase: ferment the culture inoculated with Asp...

Embodiment 3

[0056] The specific preparation process of cellulase prepared by Aspergillus mycelium (Sartorya sp.Vuill W-10) is as follows:

[0057] (1) Preparation of culture medium: Preparing according to potassium nitrate 4g, lactose 4g, urea 0.2g, dipotassium hydrogen phosphate 1.5g, Mandel's nutrient solution 2ml, bran 4g, magnesium sulfate 0.5g, calcium chloride 0.3g, sodium hydroxide The treated straw powder was prepared at a ratio of 30g to obtain a medium, and the volume was adjusted to 1000mL with deionized water, and the pH value of the medium was adjusted to 3.5 with 3mol / L hydrochloric acid; then, according to the bottled volume of 40mL / 250mL, the prepared The culture medium is divided into the fermentation vessel;

[0058] (2) Inoculation of Aspergillus miliformis seed liquid: according to 15% of the volume of the culture medium, inoculate the Aspergillus miliformis seed liquid in a fermentation container filled with medium;

[0059] (3) Preparation of cellulase: Ferment the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com