Nano particle/carbon fiber cloth composite electrode material and preparation method thereof

A composite electrode and nanoparticle technology, which is applied in hybrid capacitor electrodes, battery electrodes, nanotechnology and other directions, can solve the problems of easy shedding of active materials and easy damage to the structure of active materials. The effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

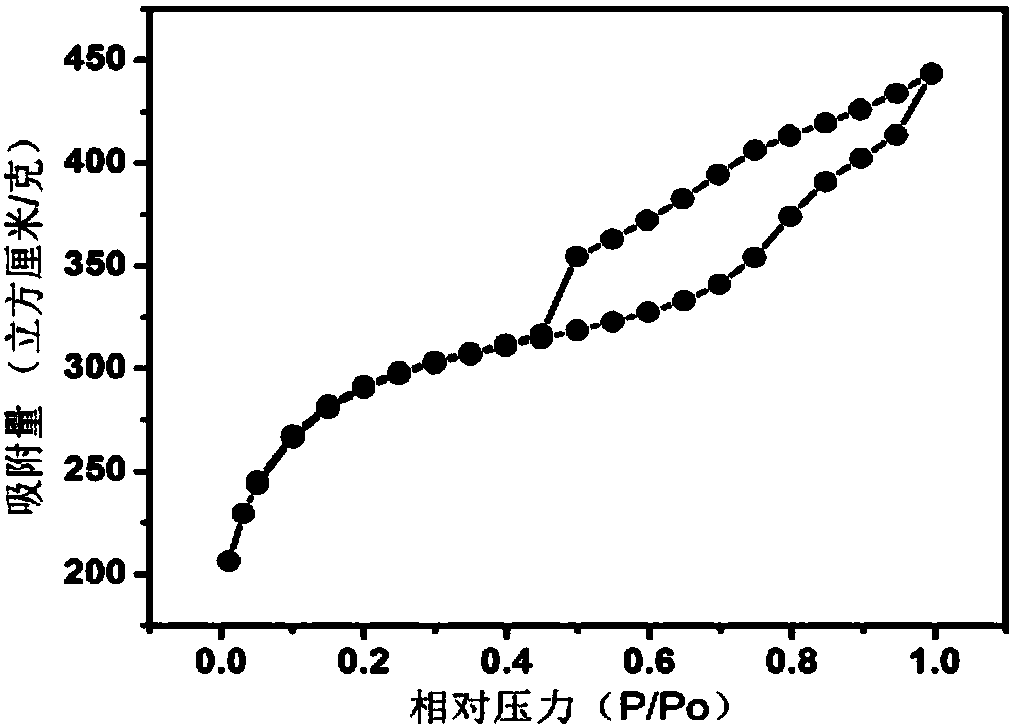

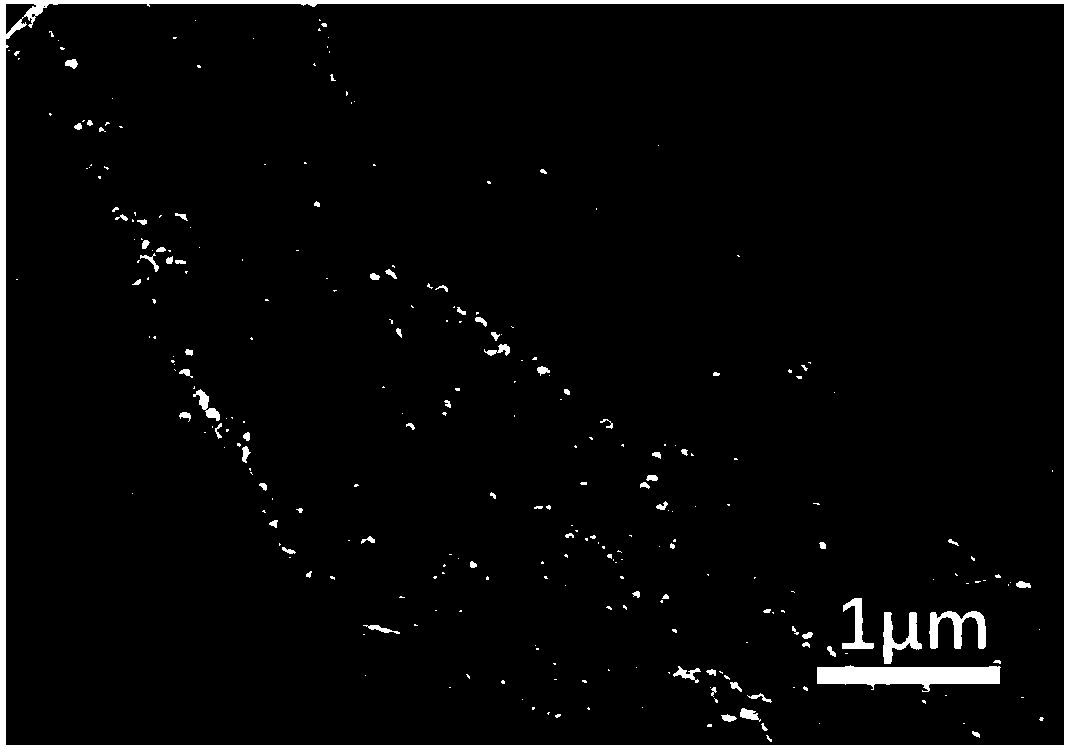

[0030] A piece of phenolic-based activated carbon fiber cloth was immersed in concentrated nitric acid at 100°C for 12 hours, and then cleaned with water and ethanol for later use. Soak the pretreated carbon fiber cloth in 0.5M nickel nitrate aqueous solution at 20°C for 6h. The carbon fiber cloth loaded with nickel nitrate was placed in a tube furnace, heated to 800°C with an argon-hydrogen mixture, and kept for 0.5h to obtain a composite of mesoporous carbon fibers embedded with nano-nickel particles. Among them, the BET specific surface area of mesoporous carbon fiber cloth is about 1100m 2 / g, the specific pore volume is about 0.5cm 3 / g, nickel particle size is 20-60nm. The obtained composite is placed in a tube furnace, and the sulfur powder is placed at one end of the tube furnace near the air inlet. The molar ratio of nickel and sulfur powder in the composite is 1:2, and the argon is heated to 200°C, heat preservation for 10h, and finally get the NiS embedded in t...

Embodiment 2

[0034] A piece of phenolic-based activated carbon fiber cloth was pretreated by immersing in concentrated nitric acid at 90°C for 4 hours, and then cleaned with water and ethanol for later use. Place the pretreated carbon fiber cloth in 0.1M ferric chloride ethanol solution and soak at 40°C for 24h. The carbon fiber cloth loaded with ferric chloride was placed in a tube furnace, heated to 900°C with argon gas, and kept for 2 hours to obtain a composite of mesoporous carbon fibers embedded with nano-iron particles. The prepared composite was placed in a tube furnace, heated to 350 °C with oxygen, and kept for 10 h, and finally the mesoporous carbon fiber cloth embedded with Fe was obtained. 2 o 3 Nanoparticle composite electrode materials.

[0035] will get Fe 2 o 3 Composite carbon fiber cloth was used as supercapacitor electrode material for three-electrode system test, platinum sheet was used as counter electrode, Ag / AgCl was used as reference electrode, 1M Na 2 SO 4 A...

Embodiment 3

[0037] A piece of phenolic-based activated carbon fiber cloth was immersed in concentrated nitric acid at 120°C for 4 hours, and then cleaned with water and ethanol for later use. Place the pretreated carbon fiber cloth in 0.05M titanium tetrachloride aqueous solution and soak at 20°C for 48h. The carbon fiber cloth loaded with titanium tetrachloride was placed in a tube furnace, heated to 1200°C with argon gas, and kept for 1 hour to obtain a composite of mesoporous carbon fibers embedded with nano-titanium oxide particles. The prepared composite was placed in a tube furnace, heated to 650° C. with ammonia gas, and kept for 10 h. Finally, a composite electrode material with TiN nanoparticles embedded in mesoporous carbon fiber cloth was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com