Preparation method of granular lithium adsorbent

A technology of lithium adsorption and particles, which is applied in the field of preparation of granular lithium adsorbents to achieve the effects of good hydrophilicity, low cost and small difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

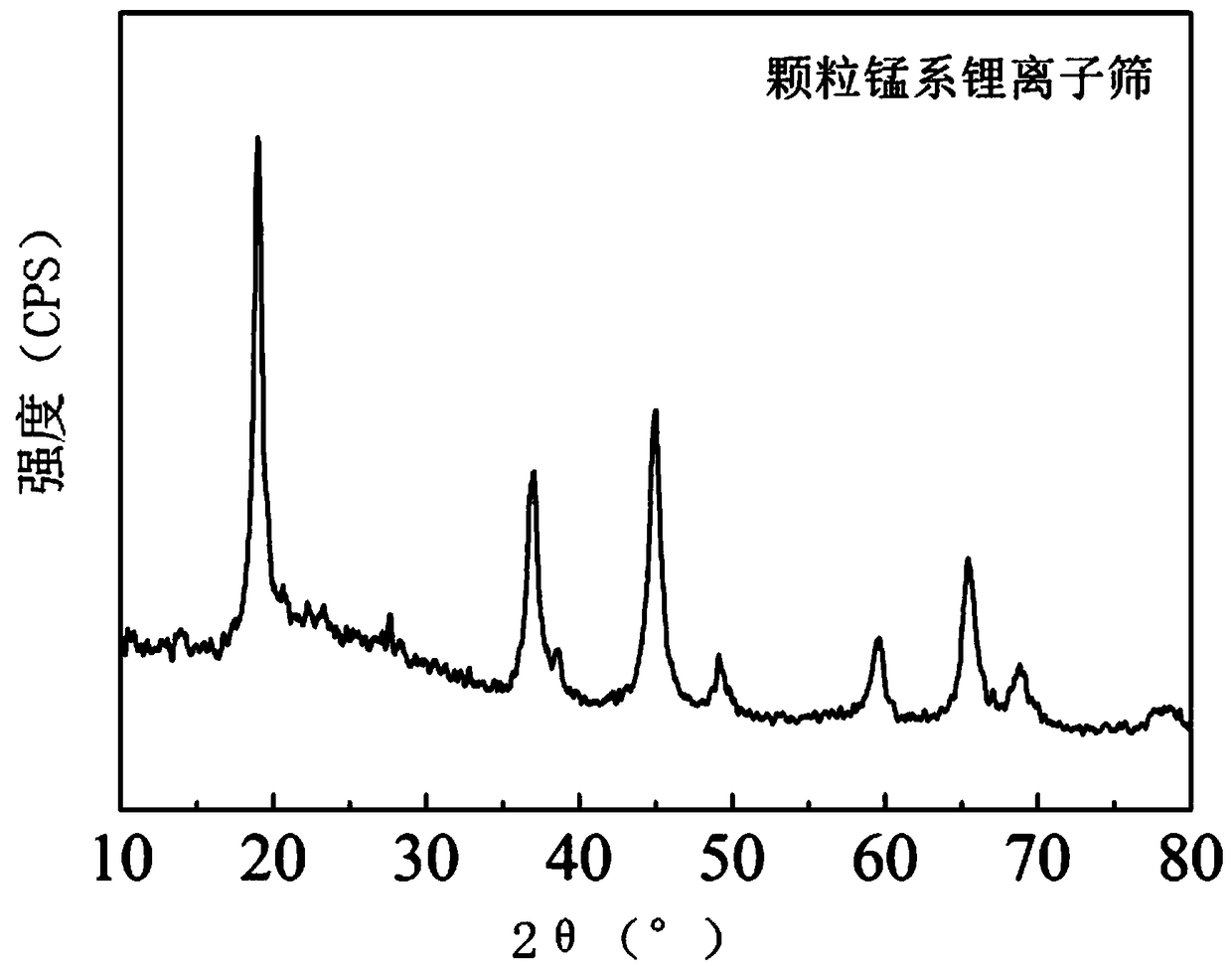

[0036] Li 4 mn 5 o 12 The preparation method of the powder comprises the following steps: after fully grinding the lithium carbonate and manganese carbonate powders in a molar ratio of 1:2.5, calcining at a temperature of 400° C. for more than 24 hours to obtain Li 4 mn 5 o 12 powder.

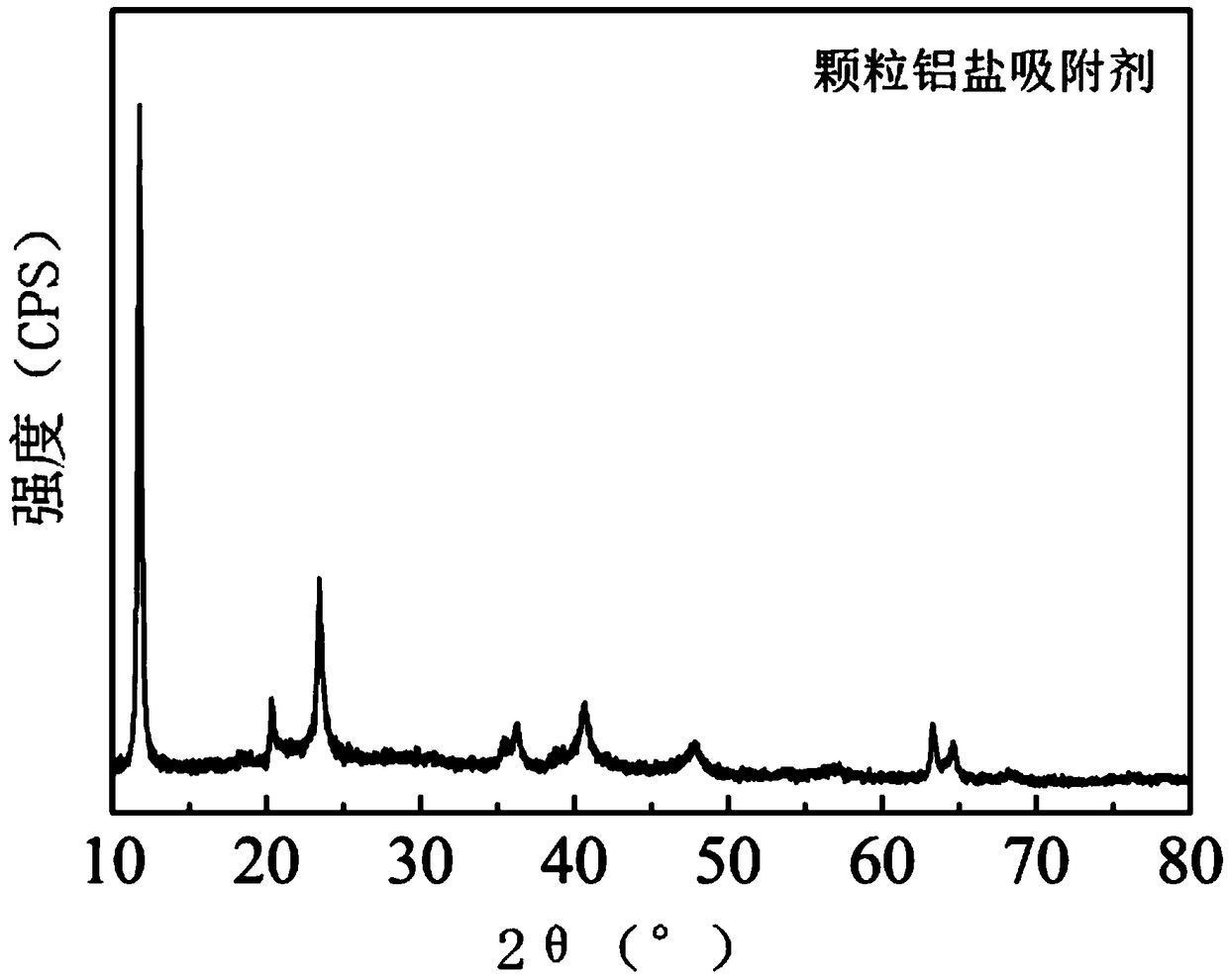

[0037] Aluminum salt adsorbent powder (LiCl 2Al(OH) 3 ·nH 2 O, the value range of n is 0-2) the preparation method comprises the following steps: the concentration is 2.28mol L -1 Lithium chloride with a concentration of 3.8mol L -1 Aluminum chloride mixed solution 175mL, with a concentration of 6mol L -1 100mL of sodium hydroxide solution was stirred and reacted, and at 80°C, using deionized water, delithiated at a ratio of 50mL / g powder for 1h to obtain aluminum salt adsorbent powder.

[0038] Li 4 Ti 5 o 12 The preparation method of the powder comprises the following steps: after fully grinding lithium carbonate and titanium dioxide powder at a mass ratio of 1.05:2.5, calcining a...

Embodiment 1

[0040] Under normal pressure and temperature at 80°C, dissolve 5.00g polyvinylidene fluoride and 1.00g polyvinyl alcohol in 20mL acetone, add 10g Li 4 mn 5 o 12 Ultrafine powder and 2.0g sodium chloride powder were stirred with a high-speed homogenizer for 8 minutes to obtain a uniform mixture; the mass ratio of various polymer polyvinylidene fluoride to organic solvents was 0.38:1; the pore-forming agent sodium chloride and organic The mass ratio of the solvent is 0.13:1; the mass ratio of the lithium adsorbent or its precursor powder to the organic solvent is 0.63:1.

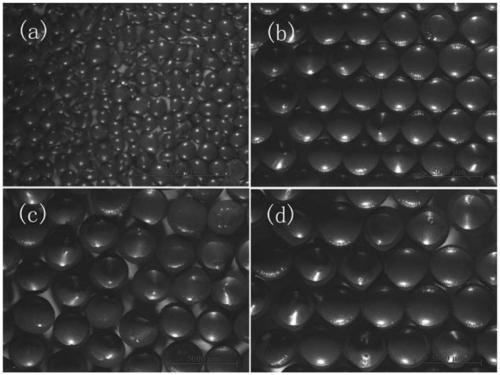

[0041] Use droppers of different calibers to drop the above homogeneous mixture into 100 mL of the mixed solution of water and ethanol with a volume ratio of 1:1, the mass ratio of the homogeneous mixture to the solution is 0.02:1, and the distance between the homogeneous mixture and the solution is 0.5 m, to obtain granular manganese-based lithium ion sieve precursors with a particle size of 0.8-3.3mm, and ...

Embodiment 2

[0043] Under normal pressure and temperature at 50°C, dissolve 4.50g ABS resin and 2.00g polyvinylpyrrolidone in 20mL chloroform, add 9g aluminum salt adsorbent powder LiCl·2Al(OH) 3 Mix with 0.5g sodium chloride powder and stir with a high-speed homogenizer for 8 minutes to obtain a uniform mixture; the mass ratio of various polymers to organic solvents is 0.22:1; the mass ratio of pore-forming agent sodium chloride to organic solvents is 0.017:1 ; The mass ratio of the lithium adsorbent or its precursor powder to the organic solvent is 0.3:1.

[0044] Use a syringe to drop the above-mentioned homogeneous mixture into 100mL of a mixed solution of water and ethanol with a volume ratio of 1:1, the mass ratio of the homogeneous mixture to the solution is 0.02:1, and the distance between the homogeneous mixture and the solution is 0.3m to obtain the particle size The aluminum salt adsorbent precursor of 1.0 mm was washed three times with 100 mL of deionized water to obtain a gran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com