Lithium-replenishing material li for positive electrode of lithium ion battery 5 feo 4 The preparation method and application of

A lithium-ion battery, cathode technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of metal lithium safety risks, severe process conditions, large investment, etc., and improve the first charge and discharge efficiency. , the effect of high purity and large charging capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of lithium-ion battery positive electrode supplement lithium material Li 5 FeO 4 The preparation method comprises the following steps:

[0028] (1) Accurately weigh 184.6g of lithium carbonate, 201.9g of ferric nitrate, 50g of citric acid, and 400g of methanol, mix well, stir at 60°C, and pass condensed water to reflux for 60min to prepare a sol;

[0029] (2) drying the sol in an oven at 120°C for 24 hours to obtain a xerogel;

[0030] (3) Under the protection of argon gas, the dry gel was pretreated at a low temperature of 450 ° C for 10 h, then cooled to room temperature, and ground. Speed up to 750°C and sinter for 24 hours, then cool naturally to room temperature to obtain lithium-ion battery cathode material Li 5 FeO 4 .

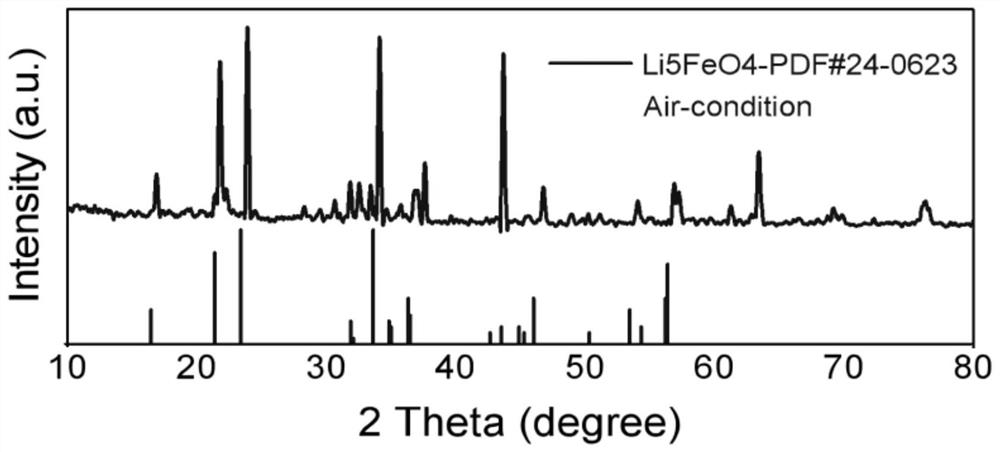

[0031] Positive electrode lithium supplement material Li 5 FeO 4 The XRD chart sees figure 1 . From the XRD structure, it can be seen that pure Li 5 FeO 4 structure, no impurity appears.

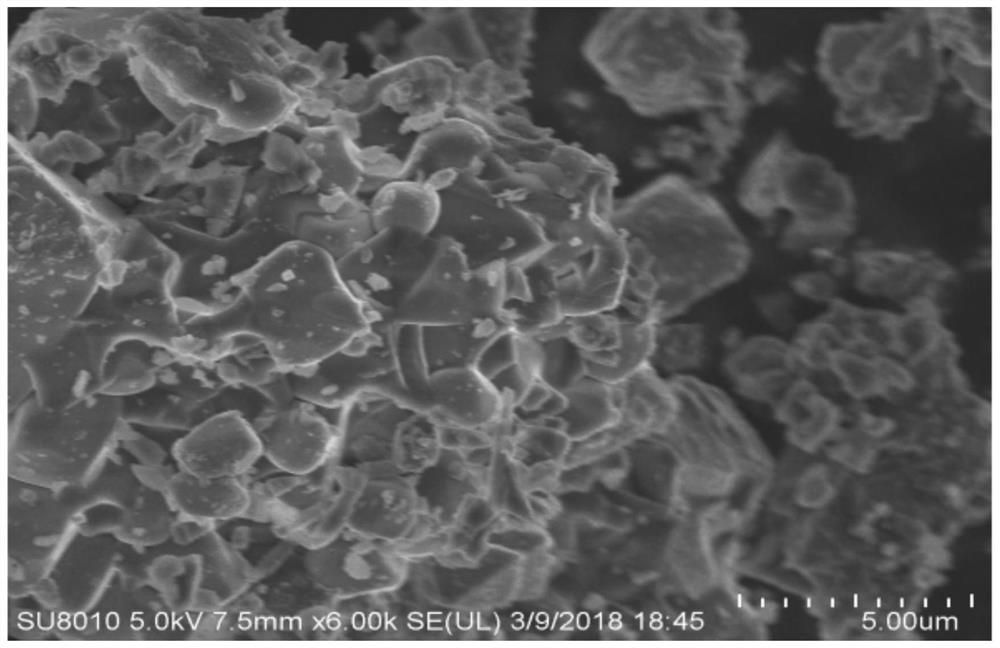

[0032] Positive electrode lithium su...

Embodiment 2

[0036] A kind of lithium-ion battery positive electrode supplement lithium material Li 5 FeO 4 The preparation method comprises the following steps:

[0037] (1) Accurately weigh 125.9g of lithium hydroxide, 201.9g of ferric nitrate, 40g of citric acid, and 400g of methanol, mix well, stir at 65°C, and pass condensed water to reflux for 50min to prepare a sol;

[0038] (2) drying the sol in an oven at 100°C for 30 hours to obtain a xerogel;

[0039] (3) Under the protection of argon gas, the dry gel was pretreated at a low temperature of 400 ° C for 10 h, then cooled to room temperature, and ground. Speed up to 700°C and sinter for 20 hours, then cool naturally to room temperature to obtain lithium-ion battery cathode material Li 5 FeO 4 .

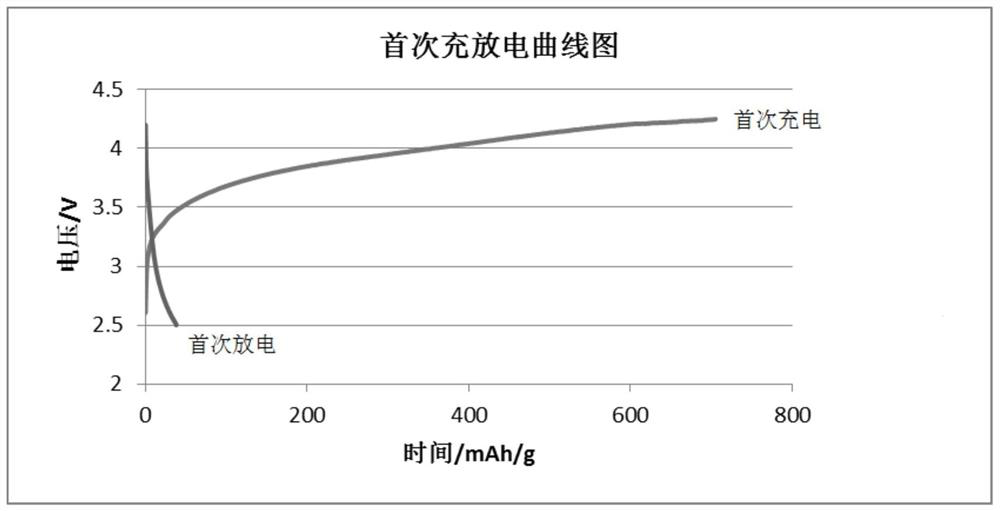

[0040] The obtained positive electrode lithium supplement material Li 5 FeO 4 , Carbon black conductive agent (SP) and binder polyvinylidene fluoride (PVDF) are mixed according to the ratio of 8:1:1 by weight, and then N-methylpyr...

Embodiment 3

[0042] A kind of lithium-ion battery positive electrode supplement lithium material Li 5 FeO 4 The preparation method comprises the following steps:

[0043] (1) Accurately weigh 125.9g of lithium hydroxide, 135.1g of ferric chloride, 50g of citric acid, and 420g of methanol, mix well, stir at 70°C, and pass condensed water to reflux for 65min to prepare a sol;

[0044] (2) drying the sol in an oven at 100°C for 28 hours to obtain a xerogel;

[0045] (3) Under the protection of argon gas, the dry gel was pretreated at a low temperature of 470°C for 8 hours, then cooled to room temperature, and ground. Speed up to 680°C and sinter for 28 hours, then cool naturally to room temperature to obtain lithium-ion battery cathode material Li 5 FeO 4 .

[0046] The obtained positive electrode lithium supplement material Li 5 FeO 4 , Carbon black conductive agent (SP) and binder polyvinylidene fluoride (PVDF) are mixed according to the ratio of 8:1:1 by weight, and then N-methylp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com