A kind of high temperature resistant hyperbranched epoxy resin and preparation method thereof

An epoxy resin and high-temperature-resistant technology, which is applied in the field of hyperbranched epoxy resin and its preparation, can solve the problems of low glass transition temperature, low heat resistance, and difficult aerospace high-temperature resistant resins, etc., to achieve improved glass Transformation temperature, short reaction time, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

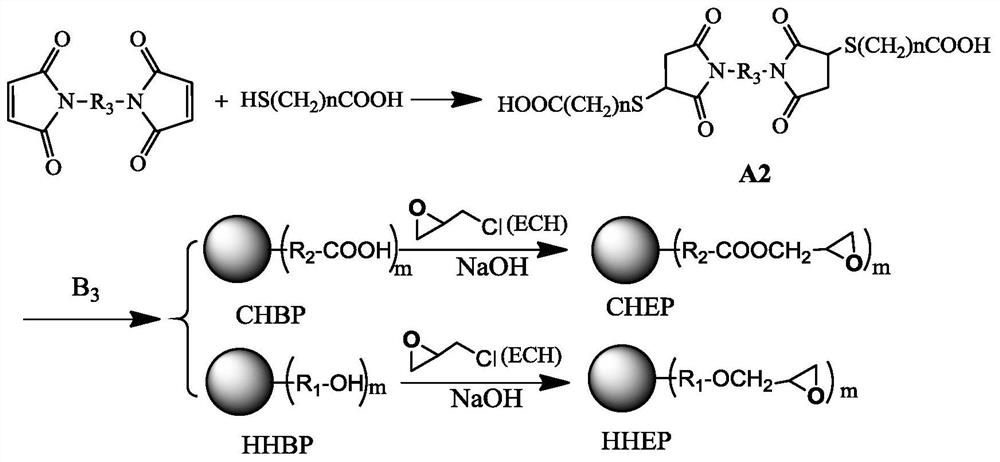

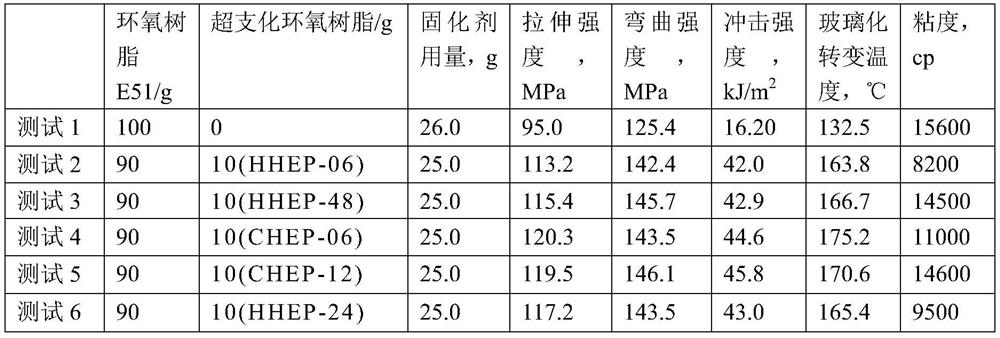

[0045] Embodiment 1 A kind of high temperature resistant hyperbranched epoxy resin, its preparation method step is as follows:

[0046] (a) 0.20mol trimethylolpropane (TMP), 0.15mol dicarboxyimide compound (A2-01), 0.15mol xylene and zinc acetate (the quality of zinc acetate is 0.5% of the total mass of TMP and A2-01) %) mixed evenly, stirred and reacted at 180°C for 10h, then vacuumized at 110°C to remove xylene to obtain a hydroxyl-terminated hyperbranched polymer (HHBP-06, containing 6mol hydroxyl groups per mole of HHBP-06), the number average The molecular weight is about 1500g / mol.

[0047] (b) Add 0.01mol HHBP-06, 0.12mol epichlorohydrin and 0.006mol tetrabutylammonium bromide into a three-necked flask, stir and react at about 120°C for 5 hours, and then vacuum out excess epichlorohydrin, Then add 0.06mol tetrahydrofuran and 0.012mol sodium hydroxide to the three-necked flask, then stir and react at -5~0°C for 8 hours, stop the reaction, let the layers stand, wash the ...

Embodiment 2

[0048] Embodiment 2 A kind of high temperature resistant hyperbranched epoxy resin, its preparation method step is as follows:

[0049] (a) 0.23mol tris (2-hydroxyethyl) isocyanurate (THEIC), 0.225mol dicarboximide compound (A2-02), 0.69mol xylene and tetrapropyl titanate (titanic acid The quality of tetrapropyl ester is 1.0% of the total mass of THEIC and A2-02) mixed uniformly, stirred and reacted at 140°C for 16h, and then vacuumized at 100°C to remove xylene to obtain a hydroxyl-terminated hyperbranched polymer (HHBP- 48, each mole of HHBP-48 contains 48mol hydroxyl groups), and the number average molecular weight is about 27000g / mol.

[0050] (b) Add 0.01mol HHBP-48, 1.92mol epichlorohydrin and 0.0024mol hexadecyltriethylammonium bromide into a three-necked flask, stir and react at about 130°C for 4 hours, and then vacuum out the excess ring Oxychloropropane, then add 1.92mol ethyl acetate and 0.096mol potassium hydroxide to the three-necked flask, then stir and react at...

Embodiment 3

[0051] Embodiment 3 A kind of high temperature resistant hyperbranched epoxy resin, its preparation method step is as follows:

[0052] (a) 0.04mol tris (2-hydroxyethyl) isocyanurate (THEIC), 0.09mol dicarboximide compound (A2-03), 0.06mol xylene, 0.02mol N-methylpyrrolidone and Tetrabutyl titanate (the quality of tetrabutyl titanate is 1.5% of the total mass of THEIC and A2-03) was mixed uniformly, stirred and reacted at 160°C for 14h, and then vacuumized at 120°C to remove xylene and N-formaldehyde Based on pyrrolidone, a carboxyl-terminated hyperbranched polymer (CHBP-06, containing 6 mol carboxyl groups per mole of CHBP-06) was obtained, with a number average molecular weight of about 3200 g / mol.

[0053] (b) Add 0.01mol CHBP-06, 0.6mol epichlorohydrin, and 0.006mol cetyltrimethylammonium bromide into a three-necked flask, stir and react at about 140°C for 3 hours, and then vacuum out the excess ring Oxychloropropane, then add 0.5mol dioxane, 0.4mol butyl acetate and 0.48...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com