High-activity-concentration green olive juice with bitterness removing function and preparation method thereof

A green olive, high-activity technology, applied in food science and other directions, can solve the problems such as the taste is not well improved, the food safety of the product is affected, the actual curative effect is reduced, etc., to achieve good health care function, improve food safety, loss low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

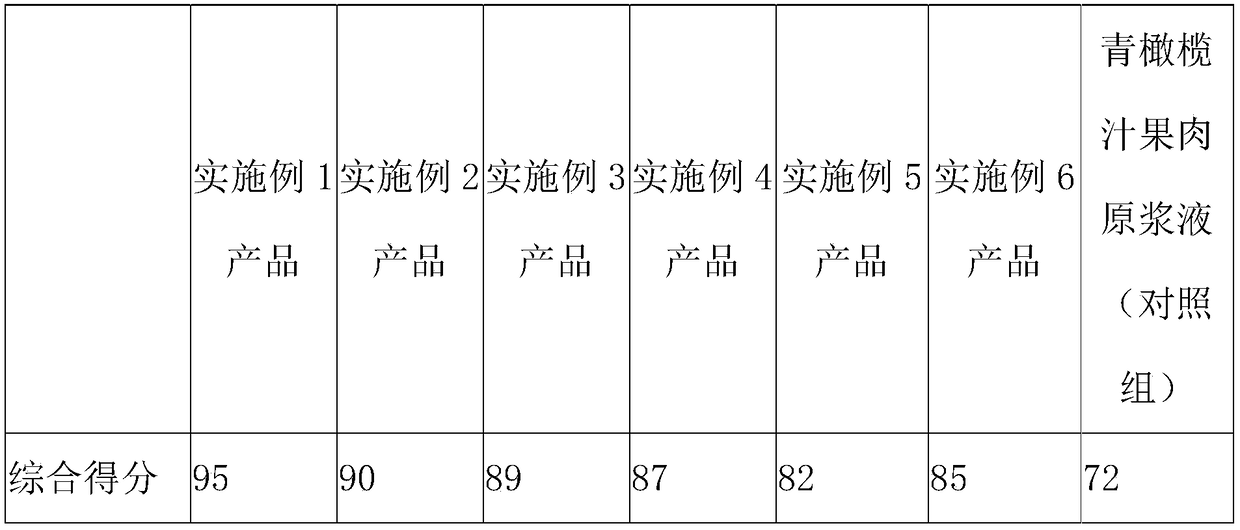

Embodiment 1

[0032] Preparation of Guya malt fermentation extract: Weigh 1.0kg of Guya and 1.0kg of malt, add 6.0kg of distilled water and decoct at 100°C for 30 minutes, filter to obtain the filtrate, add active yeast equivalent to 2.0% of the mass of the filtrate to ferment at 40°C After 3 hours, the fermented gluten malt extract was obtained for subsequent use;

[0033] Prepare the original slurry: take the green olives, wash, dry, remove the core to obtain 6.0 kg of pulp, add 10.0 kg of distilled water, and stir for 1 minute with a high-speed crusher (power 1300W) to obtain the original slurry;

[0034] Preparation of shiitake mushroom powder: crushing dried shiitake mushrooms in vacuum dehydration to obtain uniform shiitake mushroom powder;

[0035] Mixing and homogenization: Mix 10.0kg of the original slurry with 0.5kg of shiitake mushroom powder, and add 1.5kg of grain bud malt fermentation extract, mix well, and homogenize with a homogenizer (pressure: 20MPa, time 2 minutes, make t...

Embodiment 2

[0037] Preparation of Guya malt fermentation extract: Weigh 1.0kg of Guya and 1.0kg of malt, add 12.0kg of distilled water and decoct at 100°C for 30 minutes, filter to obtain the filtrate, add active yeast equivalent to 2.0% of the mass of the filtrate, and ferment for 4 hours at 30°C Afterwards, obtain the fermented extract of the glutinous malt and malt, and set aside;

[0038] Prepare the original slurry: take the green olives, wash, dry, remove the core to obtain 13.0 kg of pulp, add 10.0 kg of distilled water, and stir for 2 minutes with a high-speed crusher (power 1300W) to obtain the original slurry;

[0039] Preparation of shiitake mushroom powder: crushing dried shiitake mushrooms in vacuum dehydration to obtain uniform shiitake mushroom powder;

[0040] Mixing and homogenization: Mix 10.0kg of the original slurry with 0.5kg of shiitake mushroom powder, add 1.5kg of grain bud malt fermentation extract, add 0.2kg of lecithin, mix well, and homogenize with a homogenize...

Embodiment 3

[0042] Preparation of soybean homogenate: take 5.0kg of soybeans, soak them in distilled water for 12 hours, cook them in a boiler at 100°C for 10 minutes, cool to room temperature, homogenize pressure: 10MPa, 2 minutes, and the material temperature does not exceed 50°C to obtain soybean homogenate for later use ;

[0043]Preparation of Guya malt fermentation extract: Weigh 1.0kg of Guya and 0.5kg of malt, add 8.0kg of distilled water and decoct at 100°C for 30 minutes, filter to obtain the filtrate, add active yeast equivalent to 2.0% of the mass of the filtrate, and ferment at 45°C for 1 hour Afterwards, obtain the fermented extract of the glutinous malt and malt, and set aside;

[0044] Prepare the original slurry: take green olives, wash, dry, remove the core to obtain 10.0 kg of pulp, add 10.0 kg of distilled water, and stir for 2 minutes with a high-speed crusher (power 1300W) to obtain the original slurry;

[0045] Preparation of shiitake mushroom powder: crushing drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com