Acridine fluorescent material for detecting nerve gas analogue

A technology of fluorescent materials and analogs, applied in the field of fluorescence sensing, can solve the problems of long detection time, large-scale instruments, limited application, etc., and achieve the effects of low cost of instruments and equipment, easy operation, and simple synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preparation of spin-coated thin film: spin-coated thin film has the advantages of simple operation and low cost. The substrate used in the present invention may be a translucent optical material represented by glass sheet, quartz sheet, indium tin oxide (ITO), or filter paper. The solvent used in the present invention can be N,N-dimethylacetamide, N,N-dimethylformamide, acetonitrile, tetrahydrofuran, chloroform, dichloromethane or pyridine, or a mixture of the above solvents.

[0032] The optimized film preparation process is as follows: prepare the TPA-9AC solution at a concentration of 0.5 mg / mL, use tetrahydrofuran as a solvent, rotate at a speed of 1500 r / min, and take 30 seconds for the film to be homogenized. The thickness of the obtained thin film is about 7 nm.

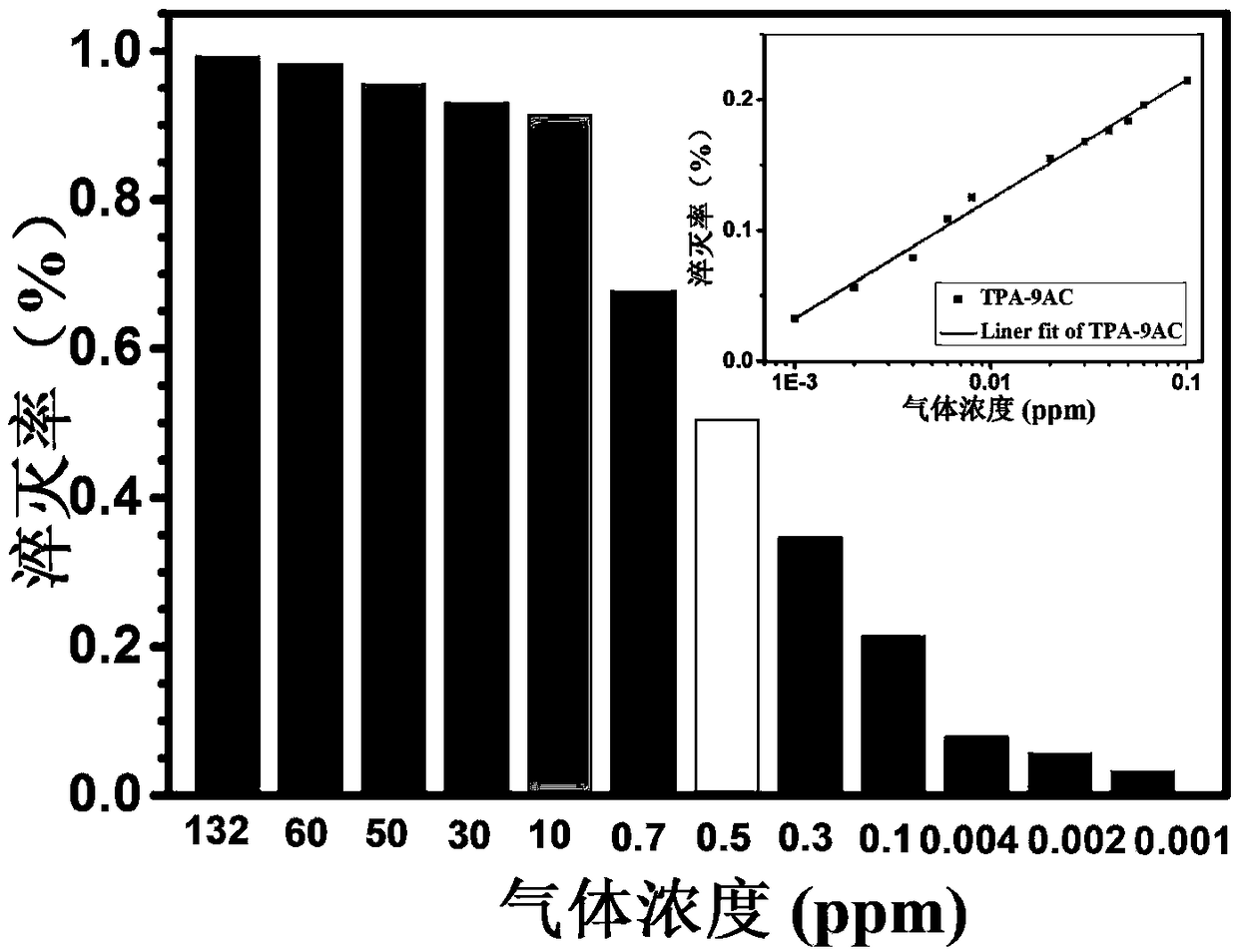

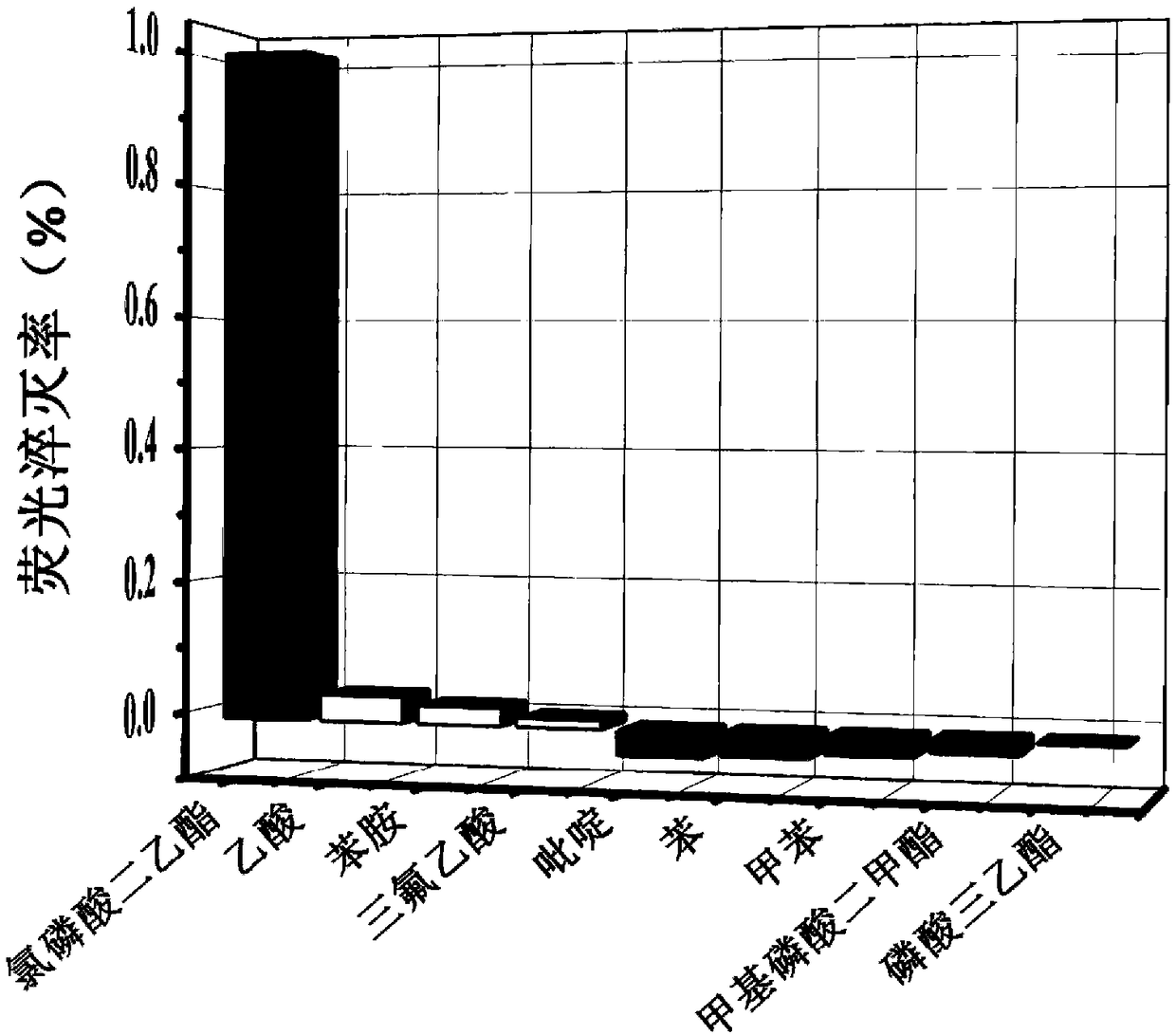

[0033] Application of this kind of thin film in DCP gas detection: the thin film prepared above is placed in different concentrations of DCP gas, and the fluorescence spectrometer records the change of...

Embodiment 1

[0036] Synthesis of compound TPA-9AC:

[0037]

[0038] Synthesis of TPA-9AC:

[0039] 213.66mg 9-chloroacridine, 371.29mg triphenylamine borate was dissolved in 12mL toluene, 8mL salt of wormwood and 6mL ethanol, under the protection of nitrogen, by liquid nitrogen freezing 8min, vacuumize 5min then, add catalyst (four ( Triphenylphosphine) palladium) 166mg, then freeze and vacuum three times to remove oxygen, and reflux at 85°C for 24h. Transfer the solution to a separatory funnel and extract. Using a mixed solvent of dichloromethane and petroleum ether as an eluent, a yellow solid was obtained by column chromatography with a yield of 60%.

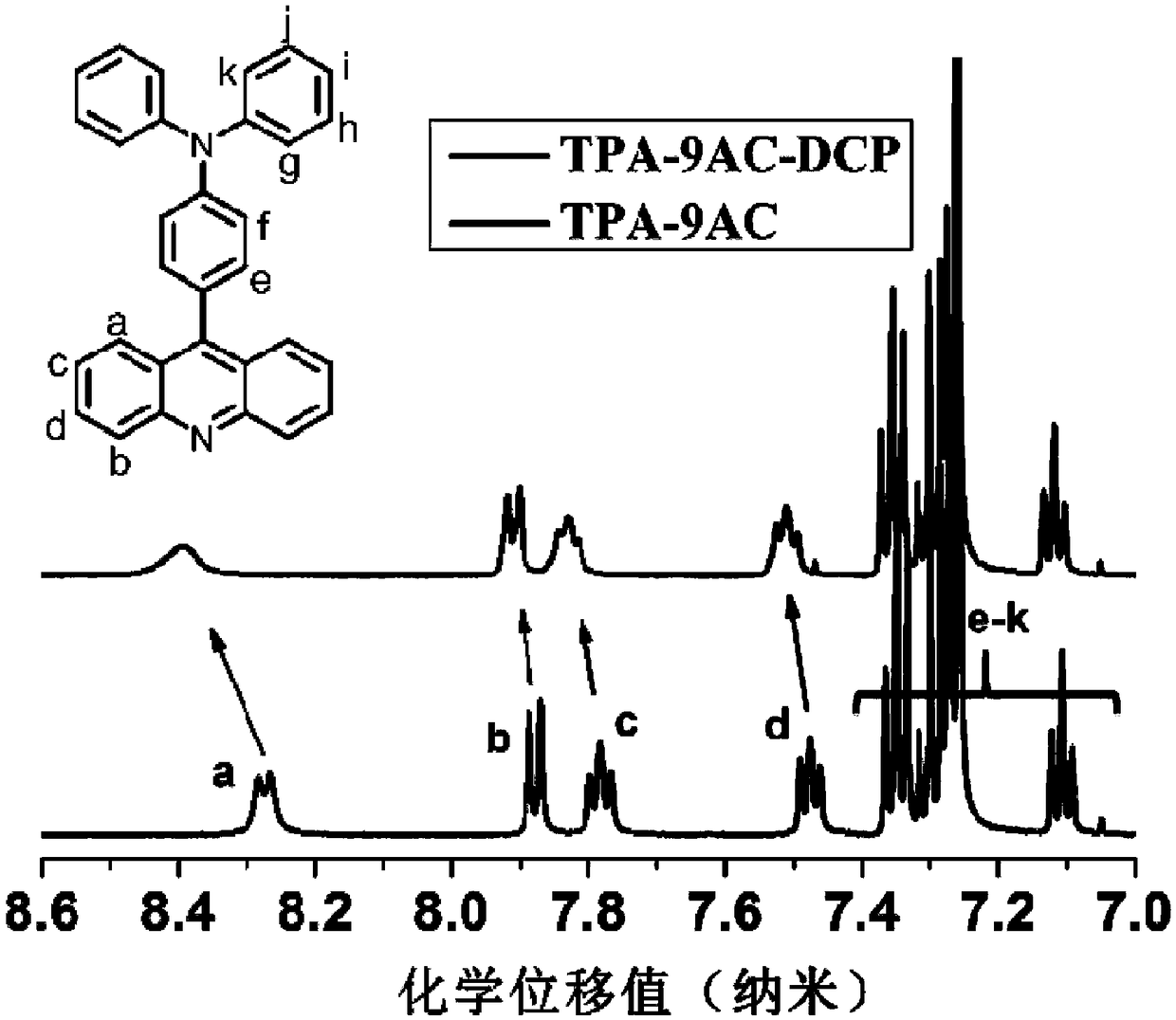

[0040] TPA-9AC: 1 H NMR (500MHz, DMSO) δ8.21(d, J=8.7Hz, 2H), 7.84-7.93(m, 2H), 7.77-7.84(d, J=8.6Hz, 2H), 7.64-7.57(m, 2H), 7.56-7.64 (m, 2H), 7.43-7.38 (m, 6H), 7.24-7.18 (m, 6H), 7.17-7.13 (t, J=7.3Hz, 2H). Mass spectrum molecular ion peak: 422.33. Elemental analysis theoretical value: C: 88.12%, H: 5.25%, N: 6.63%. Actual e...

Embodiment 2

[0042] Preparation of spin-coated thin films:

[0043] Prepare a TPA-9AC solution with a concentration of 0.5mg / mL, the solvent is tetrahydrofuran, the speed of the homogenizer is 1500r / min, and the homogenization time is 30s. Finally, the film is vacuum-dried for 10min. The thickness of the film obtained on the substrate is 7nm. ITO (Indium Tin Oxide) glass electrodes are selected. Before use, ITO needs to be ultrasonicated with water, ethanol, acetone, toluene and other solvents for 10 minutes to remove surface impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com