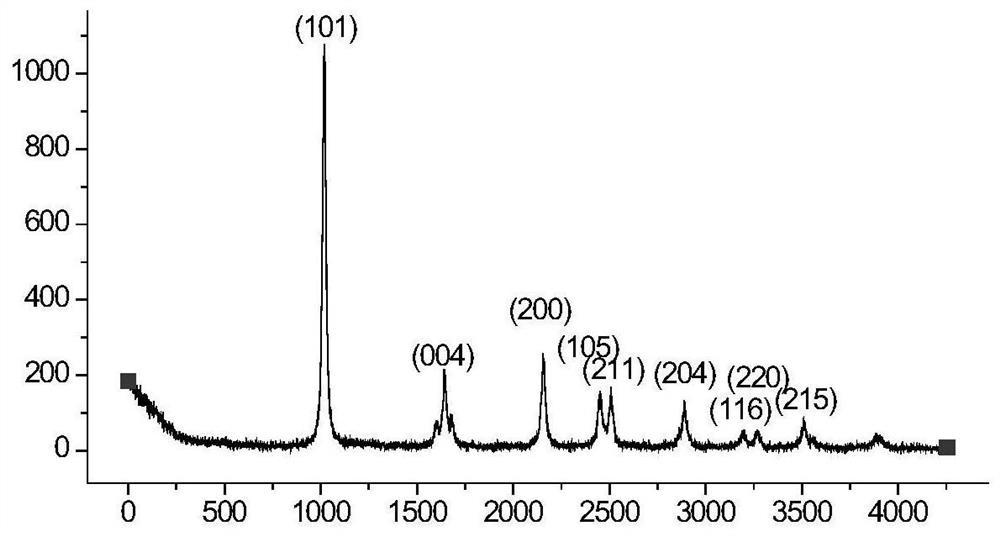

A broad-spectrum excited macroporous tio 2 Photocatalytic composite material and preparation method thereof

A composite material and photocatalytic technology, which is applied in the field of macroporous TiO2 composite material and its preparation, can solve the problems of reducing the absorption source of rare earth luminescent materials, and achieve the effects of stable photocatalytic performance, reduced desorption, and improved conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

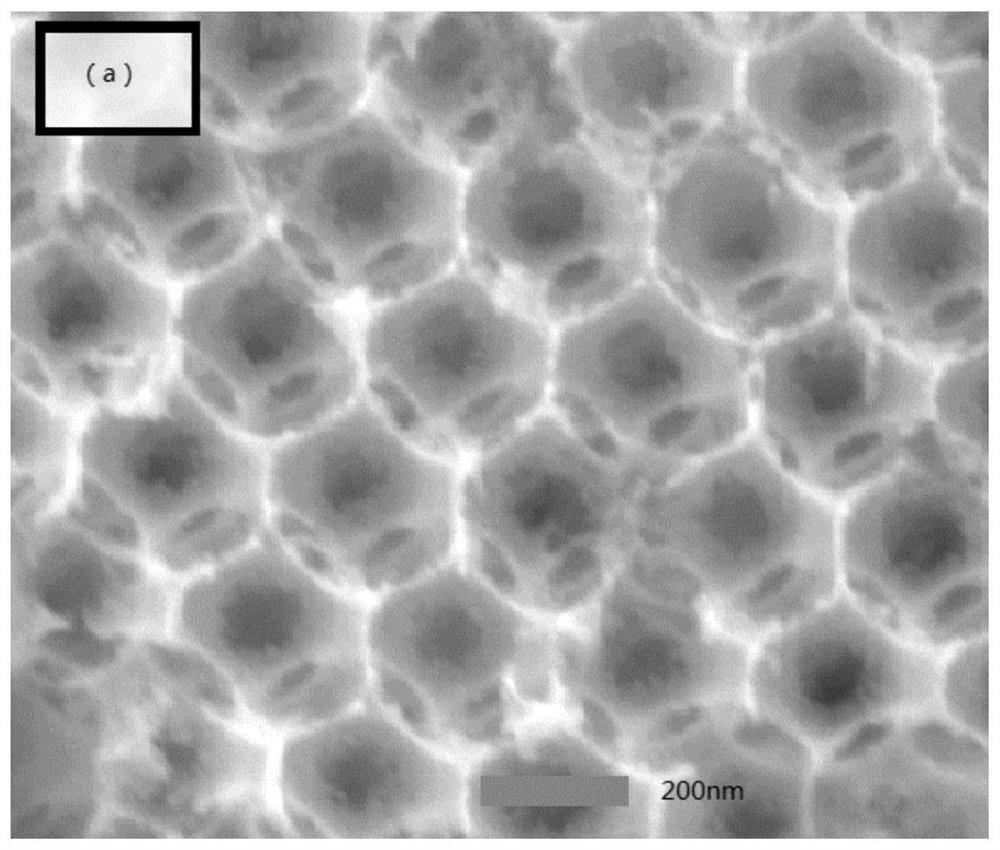

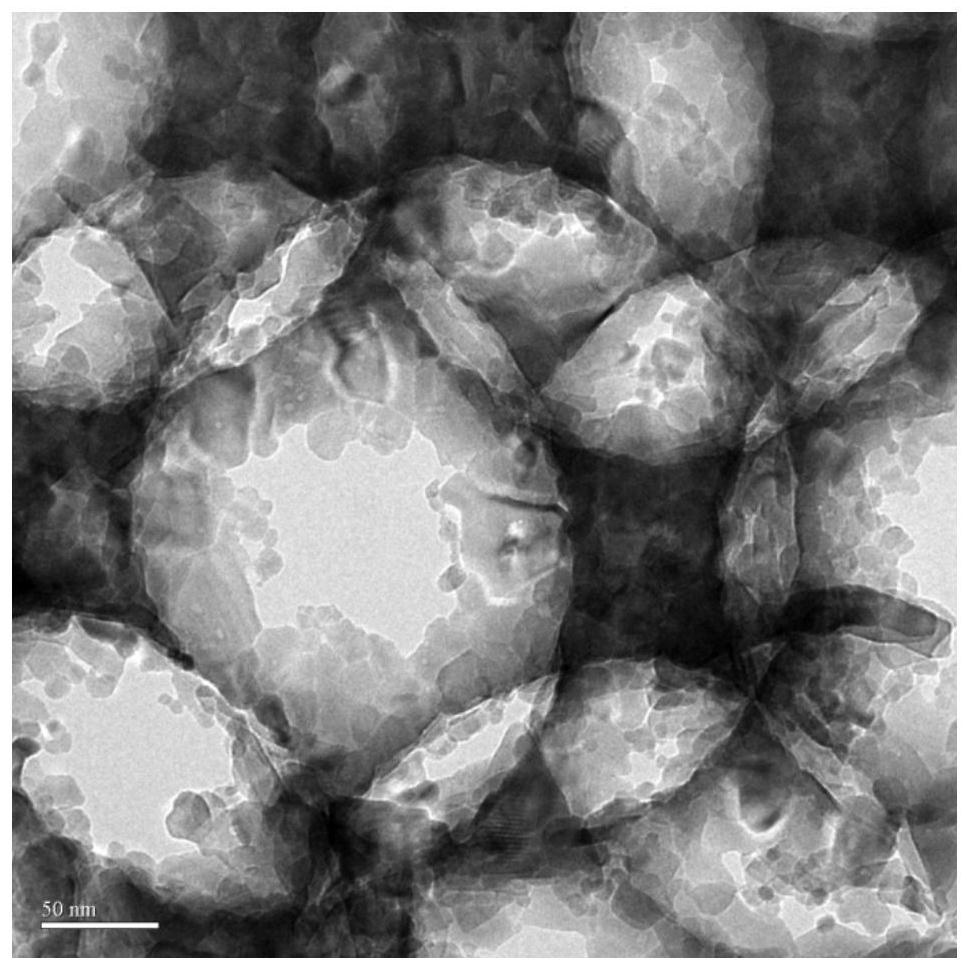

[0043] Preparation of three-dimensional ordered macroporous TiO using PMMA template 2 , including the following steps:

[0044] (1) Cleaning of methyl methacrylate (MMA)

[0045] Take 80-100mL of MMA, add sodium hydroxide to prepare a 0.1-0.2mol / L sodium hydroxide suspension, centrifuge (8000r / min, 10min) to get the supernatant, and repeat 2-3 times, then add deionized water Centrifuge to take the supernatant, and repeat 2 to 3 times;

[0046] (2) Underpressure distillation of methyl methacrylate (MMA)

[0047] The cleaned MMA obtained in step (1) is distilled under reduced pressure at a temperature of 50 to 70°C and 0 MPa for further purification; (3) Synthesis of polymethyl methacrylate (PMMA)

[0048] Take a four-neck flask, add 120-150mL deionized water, heat, and when the temperature reaches 70-80°C, pass argon, stir with a stirring paddle, and add the purified MMA obtained in step (2) into it, and wait for the temperature to recover After reaching 70-80°C, add 10-20 ...

specific Embodiment approach 2

[0063] Specific embodiment two: Preparation of three-dimensional ordered macroporous TiO by ligand-assisted template method 2 ,Specific steps are as follows:

[0064] Using dodecylamine as a template, mix 20-30g of titanium isopropoxide with 6-7g of dodecylamine, then add 500-600mL of water for hydrolysis, and a solid precipitate will immediately form in the mixture, and then add 0.3- Add 0.5mL of 37% hydrochloric acid to the mixture. The mixture was left to stand overnight at room temperature, then transferred to an oven for aging, and placed at 40-80°C for 2-4 days. Filter the mixture, put the filtrate into a sealed tube, continue aging in an oven, and place it at 100-140°C for 2-4 days. The obtained solid material is fully washed with a certain amount of methanol for 5-7 times, and finally the product is obtained by filtering and put into an oven at 150-200° C. for drying for 1-2 days to obtain a porous titanium oxide material.

[0065] Examples 6-10 Prepare three-dimens...

specific Embodiment approach 3

[0068] Specific embodiment three: Preparation of three-dimensional ordered macroporous TiO by hydrothermal crystallization method 2 ,Specific steps are as follows:

[0069] Weigh 30-40g of industrial metatitanic acid (containing about 10-15gTiO 2) into a beaker, add 50-60mL of deionized water, place the beaker in an ultrasonic cleaner and stir until it is evenly mixed. The mixed industrial metatitanic acid solution is poured into a 100mL hydrothermal reaction kettle, and then the hydrothermal crystallization reaction is carried out in an oven, the reaction temperature is set at 140-160°C, and the reaction time is 7-8h. After the reaction, the reaction kettle was taken out, and the outer surface of the reaction kettle was washed with tap water until it cooled to room temperature, and the reaction product was filtered and washed to obtain hydrated TiO 2 Precipitation, hydrated TiO obtained by industrial metatitanic acid and hydrothermal crystallization 2 Dry in an oven at 60-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com