Method for preparing closed-cell structure rubber foam material by molding physical foaming

A technology of physical foaming and closed-cell structure, applied in the field of rubber foam materials, can solve the problems of uneven product performance, harsh production environment, affecting product performance, etc., achieve easy determination of process parameters, solve poor cell uniformity, overcome product Easy to warp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

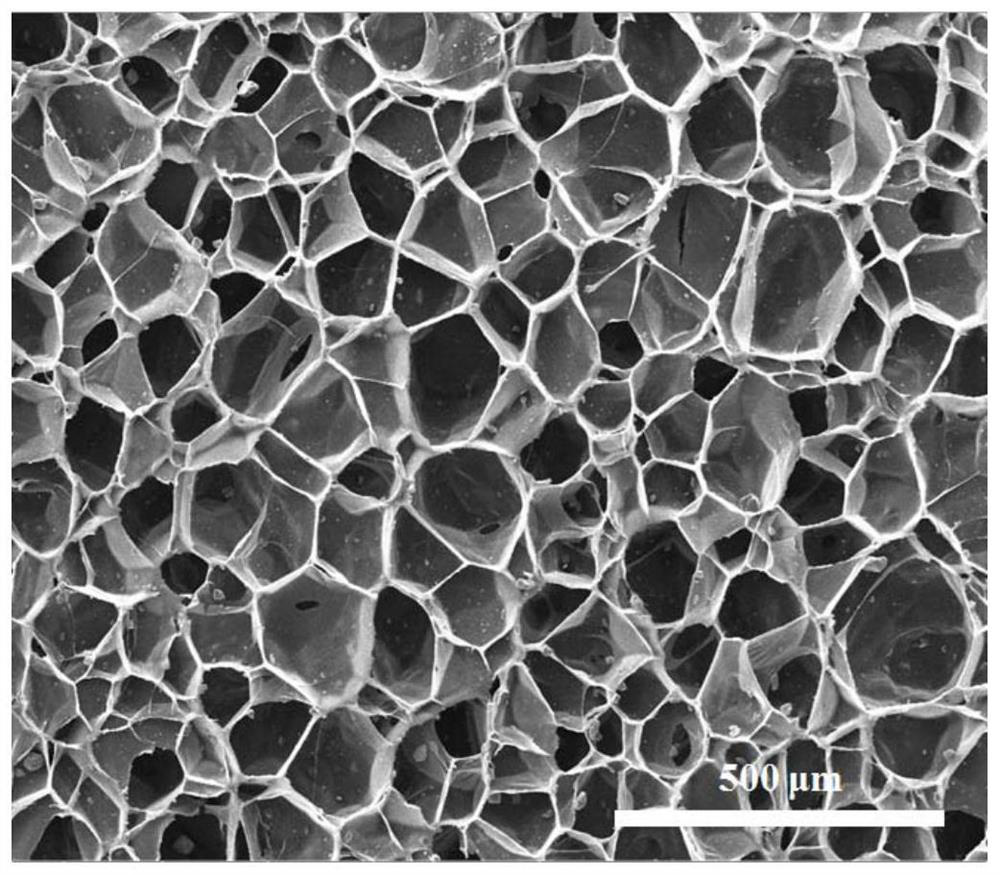

Examples

Embodiment 1

[0053] In this example, a method for preparing a closed-cell structure butyl rubber foam slab by molding physical foaming is provided, and the steps are as follows:

[0054] (1) Preparation of rubber compound

[0055] 100 mass parts of butyl rubber raw rubber, 20 mass parts of reinforcing filler calcium carbonate, 10 mass parts of carbon black, 2 mass parts of vulcanizing agent sulfur, 3 mass parts of zinc oxide, vulcanization accelerator 2,2'-dithiobis 1 mass part of benzothiazole, 0.5 mass part of tetramethylthiuram monosulfide, and 2 mass parts of plasticizer vaseline were added to a kneader and mixed uniformly at room temperature to obtain a rubber compound.

[0056] (2) Preparation of rubber body

[0057] The mixed rubber was placed on a molding machine for hot-press molding and cut and cut, and pre-vulcanized during the hot-press molding process to obtain a plate-shaped rubber body with a shore A hardness of 32 and a size of 200×200×8 mm.

[0058] (3) Molded foam

[0...

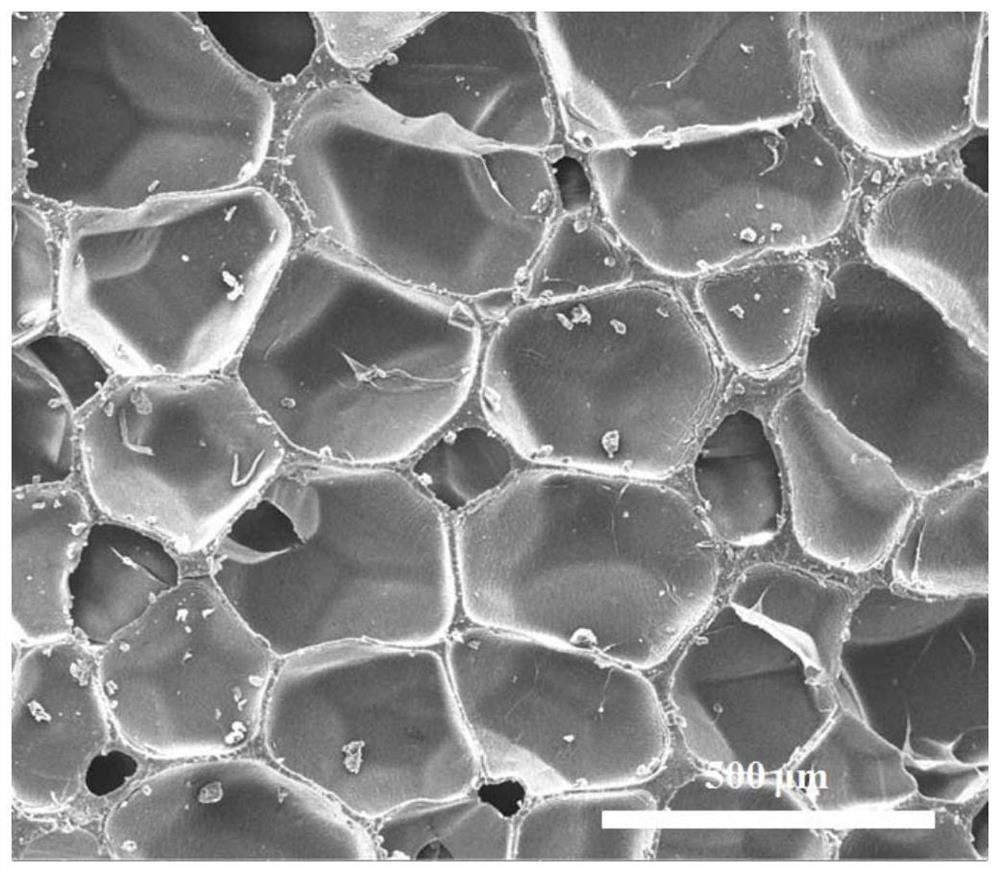

Embodiment 2

[0064] In this example, a method for preparing a closed-cell structure silicone rubber foam slab by molding physical foaming is provided, and the steps are as follows:

[0065] (1) Preparation of rubber compound

[0066] With 100 mass parts of silicone rubber raw rubber, 30 mass parts of reinforcing filler white carbon black, 25 mass parts of wollastonite, 20 mass parts of diatomaceous earth, 3 mass parts of vulcanizing agent dicumyl peroxide, structure control agent methyl Add 4 parts by mass of vinyl silicone oil into an internal mixer at 30°C and knead evenly to obtain a rubber compound.

[0067] (2) Preparation of rubber body

[0068] The mixed rubber was placed on a molding machine for hot-press molding and cut and cut. Pre-vulcanization was realized during the hot-press molding process to obtain a plate-shaped rubber body with a shore A hardness of 49 and a size of 800×600×10 mm.

[0069] (3) Molded foam

[0070] Put the rubber body in the foaming mold of the molding ...

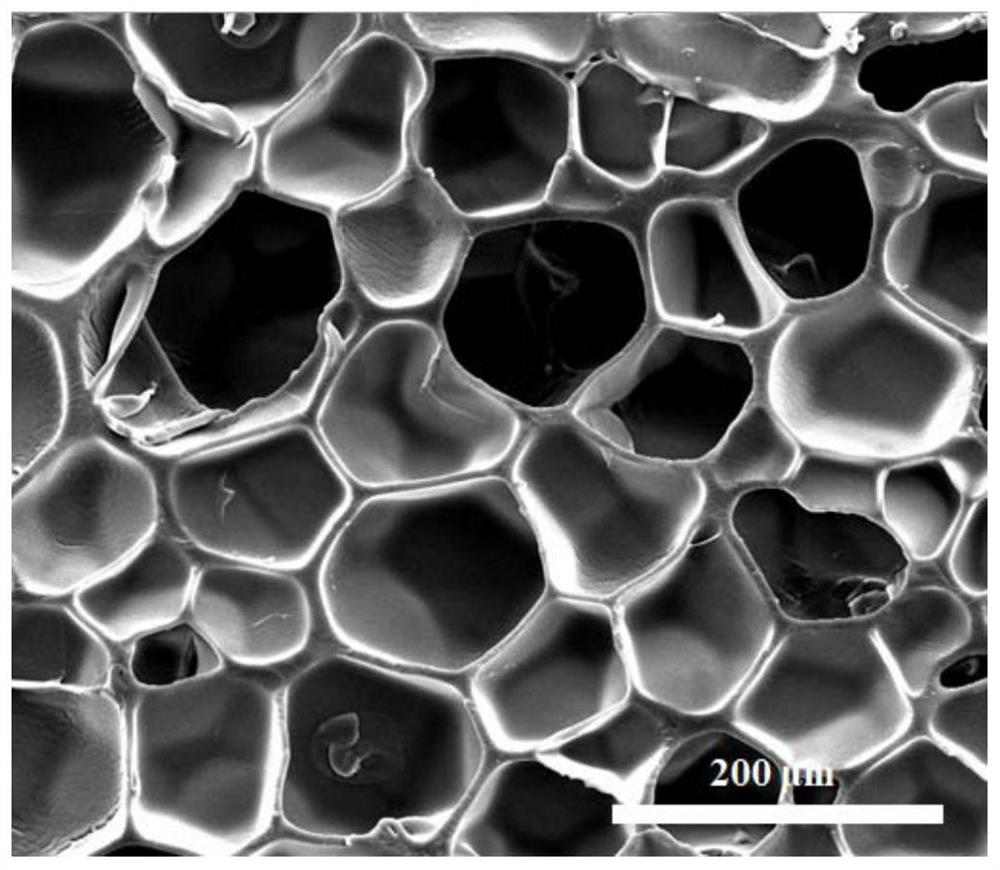

Embodiment 3

[0075] In this example, a method for preparing a closed-cell structure ethylene-vinyl acetate rubber foam slab by molding physical foaming is provided, and the steps are as follows:

[0076] (1) Preparation of rubber compound

[0077] With 100 mass parts of ethylene-vinyl acetate copolymer, 1.2 mass parts of vulcanizing agent dicumyl peroxide, 2 mass parts of flame retardant expanded graphite, 8 mass parts of ammonium polyphosphate, 20 mass parts of aluminum hydroxide, plasticizer Add 0.8 parts by mass of stearic acid into an extruder and knead at 90° C. to obtain a mixed rubber.

[0078] (2) Preparation of rubber body

[0079] The compound rubber is molded through the die of the extruder and put into the radiation cross-linking equipment for pre-vulcanization. The radiation dose of the radiation cross-linking equipment is 20kGy. After cutting, the shore A hardness is 69 and the size is 1000×500×10mm The plate-shaped rubber body.

[0080] (3) Molded foam

[0081] Put the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com