Preparation method of high-crystallinity hierarchical pore molecular sieve

A high crystallinity, molecular sieve technology, used in molecular sieve catalysts, molecular sieves and alkali exchange compounds, carbon monoxide or formate reaction preparation, etc., to improve thermal stability, crystallinity and acid strength, improve heat and mass transfer. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

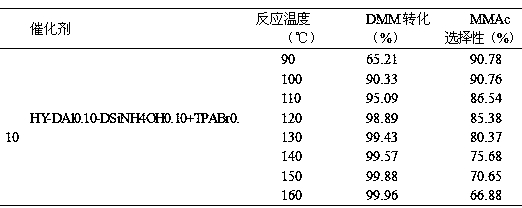

[0026] At 100 °C, 5 g HY was soaked in 0.1 mol L-1 H4EDTA solution (100 mL), stirred and refluxed for 6 h, and then dried and roasted to obtain HY-DAl0.10. 3g of HY-DAl0.10 was treated in a mixed solution of 0.1 mol L-1 tetrapropylammonium bromide (TPABr) and 0.1 mol L-1 NH4OH for 1 h, washed with water until neutral, and dried at 120 °C for 8 h. Calcined at 550°C for 6 h to remove the template agent to obtain HY-DAl0.10-DSiNH4OH0.10+TPABr0.10.

[0027] In the fixed-bed reactor, 1.0 g of the catalysts prepared above were charged respectively, and the pressure in the reaction tube was 5 MPa. CO (99.9999%) with a flow rate of 50mL / min is mixed into the reaction tube through a stainless steel reaction tank filled with methylal (DMM) (98wt%) at room temperature (25°C), and the saturated vapor of DMM is mixed into the reaction tube by adjusting the back pressure valve To keep the reaction tube pressure constant. The reaction temperature was 90-120°C, and the reaction product was ...

Embodiment 2

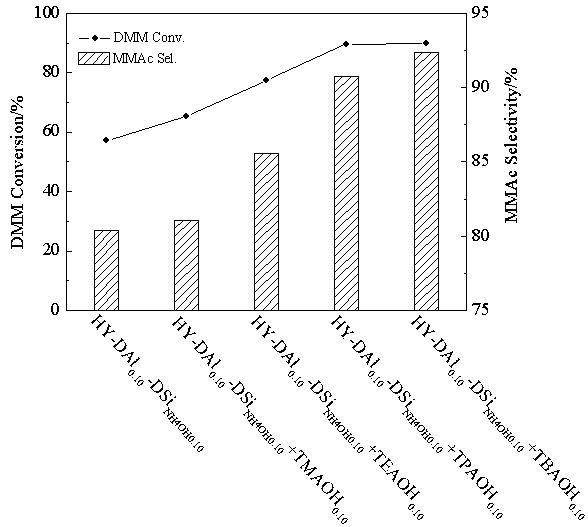

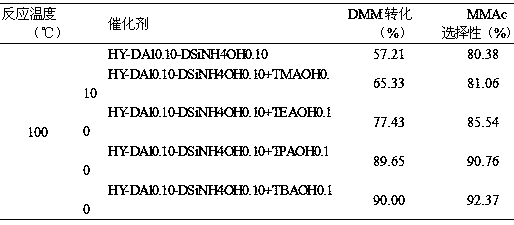

[0032]At 100°C, 5 g HY was soaked in 0.1 mol L-1 H4EDTA solution (100 mL), stirred and refluxed for 6 h, and then dried and roasted to obtain HY-DAl0.10. 3g of HY-DAl0.10 was treated in a mixed solution of 0.1 mol L-1PDA (TMAOH, TEAOH, TPAOH, TBAOH) and 0.1 mol L-1 NH4OH for 1 h, washed with water until neutral, and dried at 120 °C for 8 h. Calcined at 550°C for 6 h to remove the template to obtain HY-DAl0.10-DSiNH4OH0.10+PDA0.10.

[0033] In the fixed-bed reactor, 1.0 g of the catalysts prepared above were charged respectively, and the pressure in the reaction tube was 5.0 MPa. CO (99.9999%) with a flow rate of 50mL / min is mixed into the reaction tube through a stainless steel reaction tank filled with methylal (DMM) (98wt%) at room temperature (25°C), and the saturated vapor of DMM is mixed into the reaction tube by adjusting the back pressure valve To keep the reaction tube pressure constant. The reaction temperature was 100 °C, and the reaction products were analyzed onl...

Embodiment 3

[0038] At 100°C, 5 g HY was soaked in 0.1 mol L-1 H4EDTA solution (100 mL), stirred and refluxed for 6 h, and then dried and roasted to obtain HY-DAl0.10. Take 3g of HY-DAl0.10 and treat it in the mixed solutions with concentrations of 0.01, 0.02, 0.05, 0.1, 0.2 mol L-1TPAOH and 0.1 mol L-1 NH4OH for 1 h, wash with water until neutral, and dry at 120°C for 8 h, calcination at 550°C for 6 h to remove the template agent to obtain HY-DAl0.10-DSiNH4OH0.10+PDAy.

[0039] In the fixed-bed reactor, 1.0 g of the catalysts prepared above were charged respectively, and the pressure in the reaction tube was 5.0 MPa. CO (99.9999%) with a flow rate of 50mL / min is mixed into the reaction tube with saturated steam of DMM through a stainless steel reaction tank filled with methylal (DMM) (98wt%) at room temperature (25°C), and adjusted by adjusting the back pressure valve To keep the reaction tube pressure constant. The reaction temperature was 100 °C, and the reaction products were analyze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com