A kind of polypropylene film capacitor filling glue and preparation method thereof

A polypropylene film and capacitor technology, applied in the field of capacitors, can solve problems such as general compatibility and easy cracking, and achieve good fluidity, prevent internal cracking, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

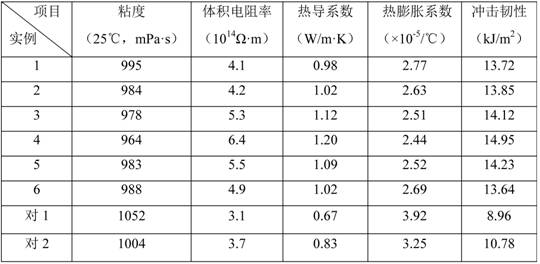

Examples

Embodiment 1

[0027] A kind of polypropylene film capacitor filling glue is made of the following raw materials in parts by weight:

[0028] 40 parts of epoxy resin, 14 parts of silicone resin, 25 parts of aluminum hydroxide, 10 parts of red phosphorus, 7 parts of modified aluminum nitride powder, 20 parts of thinner, 20 parts of curing agent and 1 part of curing accelerator;

[0029] The preparation method of described silicone resin comprises the following steps:

[0030] Adjust the pH to 4-5 with 10 parts of phenyltrimethoxysilane, 5 parts of absolute ethanol, 15 parts of water, and 30% hydrochloric acid, raise the temperature to 60°C, reflux and stir for 3 hours, and remove water and ethanol after the reaction is completed, that is have to;

[0031] The preparation method of the modified aluminum nitride powder comprises the following steps: adding 5 times the weight of isopropanol and 4% weight of titanate coupling agent to the aluminum nitride powder, ultrasonically treating it for 4...

Embodiment 2

[0041] A kind of polypropylene film capacitor filling glue is made of the following raw materials in parts by weight:

[0042] 42 parts of epoxy resin, 16 parts of silicone resin, 28 parts of aluminum hydroxide, 12 parts of red phosphorus, 8 parts of modified aluminum nitride powder, 21 parts of thinner, 22 parts of curing agent and 1.5 parts of curing accelerator;

[0043] The preparation method of described silicone resin comprises the following steps:

[0044] Adjust the pH to 4-5 with 12 parts of phenyltrimethoxysilane, 5 parts of absolute ethanol, 17 parts of water, and 30% hydrochloric acid, raise the temperature to 65°C, reflux and stir for 2 hours, and remove water and ethanol after the reaction is completed. have to;

[0045] The preparation method of the modified aluminum nitride powder comprises the following steps: adding 6 times the weight of isopropanol and 3% weight of titanate coupling agent to the aluminum nitride powder, ultrasonically treating it for 40 min...

Embodiment 3

[0055] A kind of polypropylene film capacitor filling glue is made of the following raw materials in parts by weight:

[0056] 44 parts of epoxy resin, 18 parts of silicone resin, 30 parts of aluminum hydroxide, 15 parts of red phosphorus, 10 parts of modified aluminum nitride powder, 24 parts of thinner, 24 parts of curing agent and 2 parts of curing accelerator;

[0057] The preparation method of described silicone resin comprises the following steps:

[0058] Adjust the pH to 4-5 with 13 parts of phenyltrimethoxysilane, 6 parts of absolute ethanol, 19 parts of water, and 30% hydrochloric acid, raise the temperature to 70°C, reflux and stir for 2.5 hours, and remove water and ethanol after the reaction. instant;

[0059] The preparation method of the modified aluminum nitride powder comprises the following steps: adding 7 times the weight of isopropanol and 5% by weight of titanate coupling agent to the aluminum nitride powder, ultrasonically treating for 30 minutes, filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com