Higher hydrocarbon steam conversion upper-section catalyst and preparation method thereof

A catalyst, advanced hydrocarbon technology, applied in catalyst activation/preparation, carbon compound catalysts, catalysts, etc., can solve the problems of environmental hazards, low waste consumption, and high processing costs, reducing preparation costs, relieving huge pressure, and simplifying production. The effect of the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

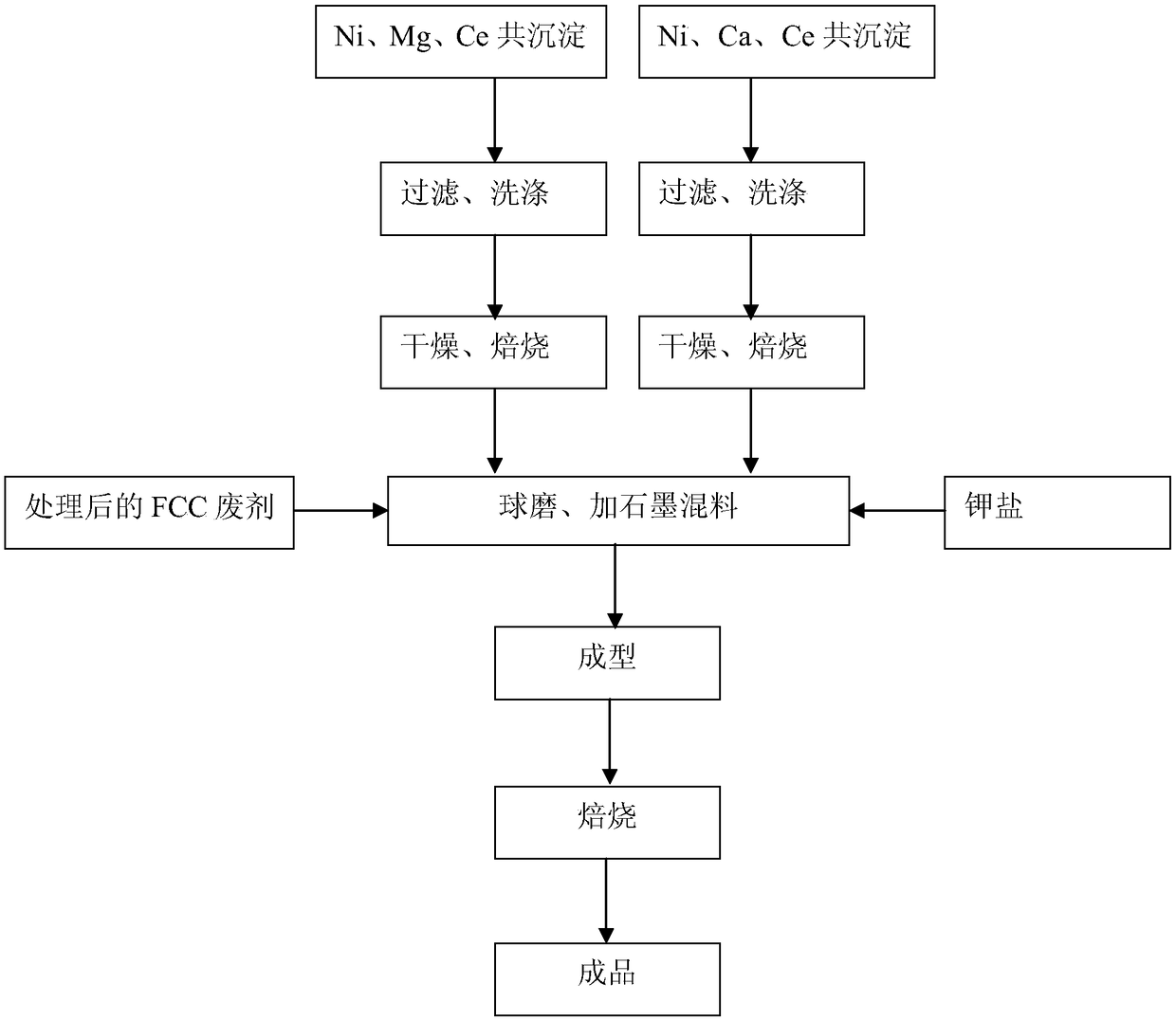

Embodiment 1

[0040] Mix 1163g of nickel nitrate, 205g of magnesium nitrate, and 17.4g of cerium nitrate to prepare a 2L solution. Dissolve 616g of sodium carbonate in water to form a 4L solution. The temperature of the nickel-magnesium-cerium solution was raised to 85° C., the stirring speed was 60 r / min, and the sodium carbonate solution was slowly dropped into it, and the titration time was controlled to be 30 minutes. After the titration, continue to stir for 30 minutes, turn off the stirring, and maintain 85°C for aging for 4 hours. After completing the above operations, wash and filter the precipitate to remove Na in the precipitate + and NO 3- , baked at 380°C for 4 hours after drying.

[0041] Mix 1045g of nickel nitrate, 1898g of calcium nitrate and 17.4g of cerium nitrate to prepare a 4L solution. Dissolve 1562g of sodium carbonate in water to form an 8L solution. The temperature of the nickel-magnesium-cerium solution was raised to 80° C., the stirring speed was 60 r / min, an...

Embodiment 2

[0045] Mix 1018g of nickel nitrate, 1019g of magnesium nitrate and 9.18g of cerium nitrate to prepare a 3L solution. Dissolve 953g of sodium carbonate in water to form a 6L solution. The temperature of the nickel-magnesium-cerium solution was raised to 85° C., the stirring speed was 60 r / min, and the sodium carbonate solution was slowly dropped into it, and the titration time was controlled to be 30 minutes. After the titration, continue to stir for 30 minutes, turn off the stirring, and maintain 85°C for aging for 4 hours. After completing the above operations, wash and filter the precipitate to remove Na in the precipitate + and NO 3- , and baked at 650°C for 2 hours after drying.

[0046] Mix 1047g of nickel nitrate, 2361g of calcium nitrate and 17.4g of cerium nitrate to prepare a 5L solution. Dissolve 1732g of sodium carbonate in water to form a 10L solution. The temperature of the nickel-magnesium-cerium solution was raised to 80° C., the stirring speed was 60 r / min...

Embodiment 3

[0050] Mix 1977g of nickel nitrate, 1230g of magnesium nitrate, and 51.9g of cerium nitrate to prepare a 4L solution. Dissolve 1500g of sodium carbonate in water to form a 10L solution. The temperature of the nickel-magnesium-cerium solution was raised to 75° C., the stirring speed was 100 r / min, and the sodium carbonate solution was slowly dropped into it, and the titration time was controlled to be 60 minutes. After the titration, continue to stir for 60 minutes, turn off the stirring, and keep aging at 75°C for 2 hours. After completing the above operations, wash and filter the precipitate to remove Na in the precipitate + and NO 3- , and baked at 420°C for 6 hours after drying.

[0051] Mix 1744g of nickel nitrate, 1794g of calcium nitrate, and 34.6g of cerium nitrate to prepare a 4L solution. Dissolve 1740g of sodium carbonate in water to form a 9L solution. The temperature of the nickel-magnesium-cerium solution was raised to 85° C., the stirring speed was 100 r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dry point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com