Fireproof and mildew-proof environment-friendly coating used for tunnels

An environment-friendly, mildew-proof technology, applied in fire-resistant coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of easy mildew, poor waterproof and anti-seepage of coatings, cracking of coatings, etc., and achieve the preparation process The effect of simple operation, excellent fireproof performance and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

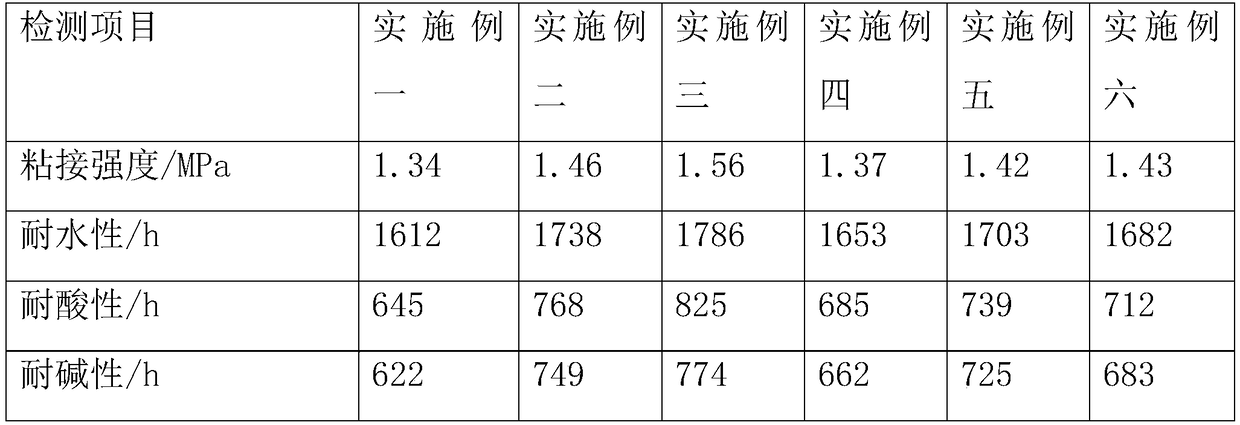

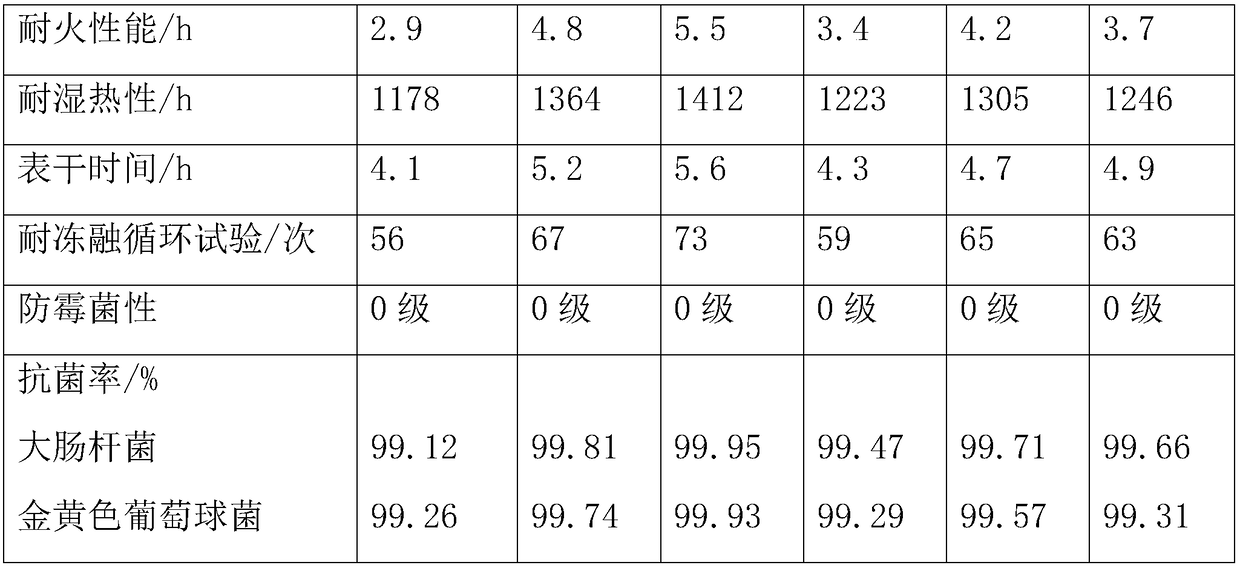

Examples

Embodiment 1

[0018] This embodiment provides a kind of environment-friendly fire-proof and mildew-proof coating for tunnels, which includes the following raw material components in parts by weight: 70 parts of alkyd resin, 30 parts of sodium silicate, 10 parts of polyacrylamide, glycidyl methacrylate 15 parts of ester, 25 parts of polyvinyl alcohol, 30 parts of shell powder, 30 parts of kaolinite, 20 parts of mica powder, 20 parts of vermiculite, 20 parts of pyrophyllite, 10 parts of zinc oxide, 10 parts of hokutou stone powder, 10 parts of charcoal powder , 15 parts of Moringa root powder, 15 parts of Polygonum grass powder, 10 parts of magnesium hydroxide, 8 parts of tangerine peel powder, 5 parts of hydroxypropyl methylcellulose, 2 parts of mineral oil defoamer, aluminate coupling 1.5 parts of agent, 70 parts of deionized water.

[0019] In this embodiment, the root powder of Moringa oleifera is obtained by freeze-drying the root of Moringa oleifera and then ultrafine grinding at low te...

Embodiment 2

[0026] This embodiment provides a kind of environment-friendly fire-proof and mildew-proof coating for tunnels, which includes the following raw material components in parts by weight: 75 parts of alkyd resin, 30 parts of sodium silicate, 15 parts of polyacrylamide, glycidyl methacrylate 18 parts of ester, 25 parts of polyvinyl alcohol, 35 parts of shell powder, 35 parts of kaolinite, 20 parts of mica powder, 20 parts of vermiculite, 20 parts of pyrophyllite, 15 parts of zinc oxide, 15 parts of hokutou stone powder, 10 parts of charcoal powder , 18 parts of Moringa root powder, 18 parts of Polygonum grass powder, 10 parts of magnesium hydroxide, 10 parts of tangerine peel powder, 7 parts of hydroxypropyl methylcellulose, 3 parts of mineral oil defoamer, aluminate coupling 2 parts of agent, 75 parts of deionized water.

[0027] In this embodiment, the root powder of Moringa oleifera is obtained by freeze-drying the root of Moringa oleifera and then ultrafine grinding at low tem...

Embodiment 3

[0034]This embodiment provides a kind of environment-friendly fire-proof and mildew-proof coating for tunnels, which includes the following raw material components in parts by weight: 75 parts of alkyd resin, 35 parts of sodium silicate, 15 parts of polyacrylamide, glycidyl methacrylate 18 parts of ester, 27 parts of polyvinyl alcohol, 35 parts of shell powder, 35 parts of kaolinite, 25 parts of mica powder, 25 parts of vermiculite, 25 parts of pyrophyllite, 15 parts of zinc oxide, 15 parts of hokutolite powder, 12 parts of charcoal powder , 20 parts of Moringa root powder, 20 parts of Polygonum grass powder, 15 parts of magnesium hydroxide, 10 parts of tangerine peel powder, 10 parts of hydroxypropyl methylcellulose, 4 parts of mineral oil defoamer, aluminate coupling 2 parts of agent, 75 parts of deionized water.

[0035] In this embodiment, the root powder of Moringa oleifera is obtained by freeze-drying the root of Moringa oleifera and then ultrafine grinding at low temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com