Silicon carbide film and preparation method thereof

A silicon carbide membrane and silicon carbide-based membrane technology, which is applied in the field of membrane separation, can solve the problems of scarcity of varieties and difficult to meet different application fields, and achieve the effects of solid material, large flux and high filtration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

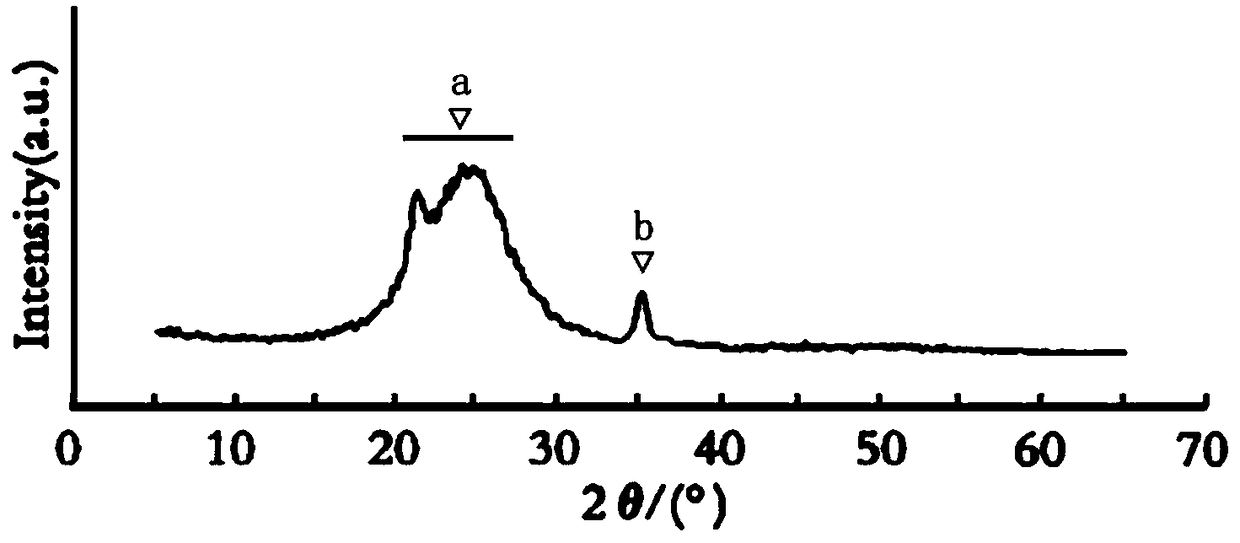

Image

Examples

preparation example Construction

[0022] The preparation method of the silicon carbide film provided by the invention comprises the following steps:

[0023] S1, mixing graphene with a silicon carbide precursor and a first solvent to form a first mixed solution, drying to obtain a powder, wherein the silicon carbide precursor reacts to form an intermediate product during the drying process, the powder The body is graphene modified through the intermediate product;

[0024] S2, mixing the powder with a second solvent to obtain a second mixed liquid;

[0025] S3, providing a silicon carbide base film, forming the second mixed solution on the silicon carbide base film to obtain a preform;

[0026] S4, sintering the preform to obtain a silicon carbide film comprising a graphene composite film and a silicon carbide base film, wherein the intermediate product reacts to form silicon carbide during the sintering process, and the graphene is formed by the carbonization Silicon is closely attached to the silicon carbi...

Embodiment 1

[0058] Mix and mix graphene, amino polysiloxane, and ethanol aqueous solution according to the mass ratio of 10:5:85, wherein the mass ratio of ethanol and water in the ethanol aqueous solution is 50:50, and then pass through a planetary mill filled with silicon carbide grinding balls Disperse by ball milling for 2 hours to obtain the first mixed liquid. Then put the first mixed liquid in an oven, dry it at 120° C. for 24 hours, take it out and pulverize it to form a powder.

[0059] Mix powder, carboxymethyl cellulose, polyethyleneimine, modified polydimethylsiloxane, and solvent according to the mass ratio of 5:0.05:0.1:0.02:94.83, wherein the solvent is ethanol, ammonia water and water It is mixed according to the mass ratio of 60:5:35, and then dispersed by a planetary mill filled with silicon carbide grinding balls for 16 hours, and then dispersed by ultrasonic waves for 30 minutes to obtain the second mixed solution.

[0060] Fix and seal the two ends of the silicon car...

Embodiment 2

[0063] Graphene oxide, modified polydimethylsilane, and ethanol aqueous solution are mixed and mixed according to the mass ratio of 30:20:50, wherein the mass ratio of ethanol and water in the ethanol aqueous solution is 30:70, and then filled with silicon carbide grinding balls The planetary mill was used to disperse for 10 hours to obtain the first mixed liquid. Then put the first mixed solution in an oven, dry it at 100° C. for 16 hours, take it out and pulverize it to form a powder.

[0064] Mix the powder, carboxyethyl cellulose, tetramethylammonium hydroxide, polyether siloxane, and solvent according to the mass ratio of 10:0.1:0.4:0.08:89.42, wherein the solvent is ethanol, ammonia water and water by mass Mixed at a ratio of 40:3:55, then dispersed by a planetary ball mill filled with silicon carbide grinding balls for 20 hours, and then dispersed by ultrasonic waves for 40 minutes to obtain the second mixed solution.

[0065] Fix and seal the two ends of the silicon c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com