Soil remediation agent and preparation method thereof

The technology of a soil remediation agent and a high boiling point solvent is applied in the field of soil remediation, and can solve the problems of no insect and bacteria prevention and fertilization effects, a narrow crop range, and poor remediation effect, achieving low equipment dependence and a preparation method. And the use method is simple and easy, and the effect of improving the repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

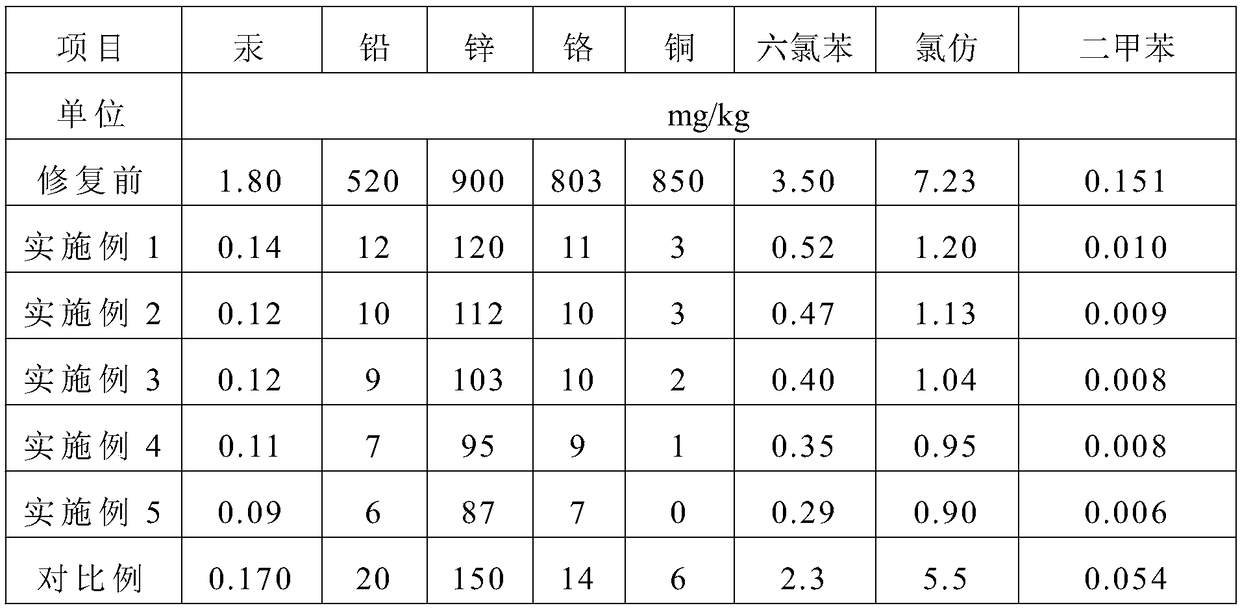

Examples

Embodiment 1

[0034] A soil remediation agent, consisting of the following raw materials in parts by weight: 30 parts of ferrous fumarate-based ionic organic fertilizer, 5 parts of activated sludge, 1 part of starch-modified graphene oxide, 2 parts of coconut shell activated carbon, bamboo 1 part of leaf powder.

[0035] The preparation method of described ferrous fumarate-based ionic organic fertilizer comprises the steps:

[0036] ⅠDissolve 1510g of quaternary ammonium salt, 20g of ferrous fumarate, 10g of L-vinylglycine, and 0.2g of azobisisobutyronitrile in 150g of dimethyl sulfoxide, stir and react for 4 hours under a nitrogen atmosphere at 70°C, and then Precipitate in acetone, place the precipitated polymer in a vacuum oven at 70°C and bake for 10 hours to obtain intermediate product A;

[0037] Ⅱ The intermediate product A20g prepared by step I, [[[[(2R,3S,4R,5R)-5-(6-aminopurine)-3,4-dihydroxytetrahydrofuran-2-yl]methoxy -Hydroxyphosphoryl]oxyl-hydroxyphosphoryl]amino]phosphonic ...

Embodiment 2

[0046] A soil remediation agent, consisting of the following raw materials in parts by weight: 33 parts of ferrous fumarate-based ionic organic fertilizer, 7 parts of activated sludge, 2 parts of starch-modified graphene oxide, 4 parts of coconut shell activated carbon, bamboo 2 parts of leaf powder.

[0047] The preparation method of described ferrous fumarate-based ionic organic fertilizer comprises the steps:

[0048] ⅠDissolve 1510g of quaternary ammonium salt, 20g of ferrous fumarate, 10g of L-vinylglycine, and 0.25g of azobisisoheptanonitrile in 160g of N,N-dimethylformamide, in a helium atmosphere at 72°C The reaction was stirred for 4.5 hours, and then precipitated in acetone, and the precipitated polymer was dried in a vacuum oven at 72°C for 11 hours to obtain intermediate product A;

[0049] Ⅱ The intermediate product A20g prepared by step I, [[[[(2R,3S,4R,5R)-5-(6-aminopurine)-3,4-dihydroxytetrahydrofuran-2-yl]methoxy -Hydroxyphosphoryl]oxyl-hydroxyphosphoryl]ami...

Embodiment 3

[0058] A soil remediation agent, consisting of the following raw materials in parts by weight: 35 parts of ferrous fumarate-based ionic organic fertilizer, 8 parts of activated sludge, 3 parts of starch-modified graphene oxide, 5 parts of coconut shell activated carbon, bamboo 4 parts of leaf powder.

[0059] The preparation method of described ferrous fumarate-based ionic organic fertilizer comprises the steps:

[0060] ⅠDissolve 1510g of quaternary ammonium salt, 20g of ferrous fumarate, 10g of L-vinylglycine, and 0.3g of azobisisobutyronitrile in 175g of N-methylpyrrolidone, and stir for 5 hours in a neon atmosphere at 75°C , and then precipitated in acetone, and placed the precipitated polymer in a vacuum oven at 75°C for 13.5 hours to obtain intermediate product A;

[0061] Ⅱ The intermediate product A20g prepared by step I, [[[[(2R,3S,4R,5R)-5-(6-aminopurine)-3,4-dihydroxytetrahydrofuran-2-yl]methoxy -Hydroxyphosphoryl] oxygen group-hydroxyphosphoryl] amino] phosphonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com