Full-priced pellet feed during dry period of milk goats as well as preparation method and application thereof

A technology of pellet feed and dry milk period, which is applied in application, animal feed, animal feed, etc., can solve the problems of health status and production performance decline, endanger human health, and frequent dystocia, so as to reduce the risk of toxins such as aflatoxin, The effect of ensuring health and safety and improving the survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Preparation method of complete pellet feed

[0040] The preparation method of the full-price granular feed for dairy goats during the dry period of milking provided by the invention comprises the following steps:

[0041] Step 1: taking the crushed corn according to parts by weight, and sieving to obtain corn flour;

[0042] Step 2: taking and pulverizing the alfalfa powder, soybean meal, cotton meal, sprayed corn husk, soybean meal, apple pomace, sesame cake, sunflower husk and corn germ cake in parts by weight to obtain a mixed powder;

[0043] Step 3: taking other raw materials by weight, and mixing them evenly with the corn flour obtained in step 1 and the mixed powder obtained in step 2 to obtain a mixture;

[0044] Step 4: Granulating the mixture obtained in Step 3 to obtain granules.

[0045] In some embodiments, the screening in step 1 adopts a double-layer primary cleaning screen, the upper screen mesh of the double-layer primary cleaning sieve is 10mm, and t...

Embodiment 1

[0059] Weigh the following raw materials in parts by weight: 33 parts of corn, 9 parts of wheat bran, 7 parts of alfalfa powder, 8 parts of soybean meal, 3 parts of cotton meal, 3 parts of sprayed corn husks, 10 parts of soybean hulls, 8 parts of apple pomace, 2 parts of sesame cake, 3 parts of sunflower shell, 5.5 parts of corn germ cake, 4 parts of wheat flour, 1.5 parts of stone powder, 0.5 part of calcium hydrogen phosphate, 0.7 part of sodium chloride, 0.5 part of sodium bicarbonate, 0.2 part of ruminant yeast, compound 0.03 part of enzyme preparation, 0.15 part of calcium sulfate, 0.2 part of sweetener, 0.50 part of bentonite, 0.02 part of antifungal agent, 0.1 part of trace element additive, and 0.1 part of multivitamin.

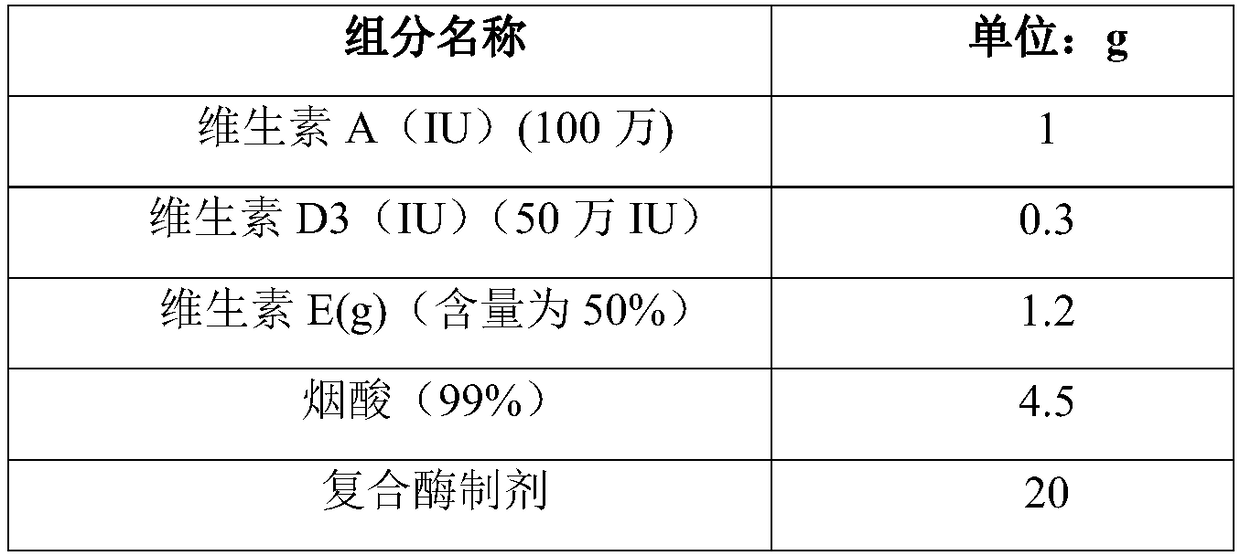

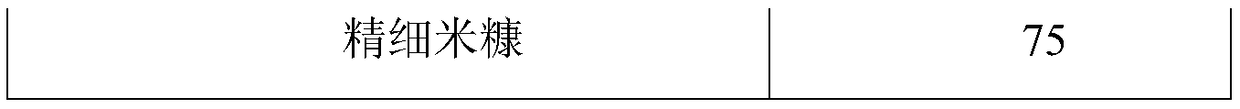

[0060] Wherein, every 100g of trace element additives is composed of the formula in Table 1, and every 102g of multivitamin is composed of the formula in Table 2.

[0061] Table 1 Trace element additive formula table

[0062] component name ...

Embodiment 2

[0069] Weigh the following raw materials by weight: 28 parts of corn, 10 parts of wheat bran, 7.5 parts of alfalfa powder, 8 parts of soybean meal, 3 parts of cotton meal, 3 parts of sprayed corn husks, 10 parts of soybean hulls, 9 parts of apple pomace, sesame seeds 3 parts of cake, 3.5 parts of sunflower shell, 6 parts of corn germ cake, 4.8 parts of wheat flour, 1.2 parts of stone powder, 0.8 part of calcium hydrogen phosphate, 0.6 part of sodium chloride, 0.5 part of sodium bicarbonate, 0.3 part of ruminant yeast, compound enzyme 0.03 part of preparation, 0.2 part of sweetener, 0.50 part of bentonite, 0.02 part of antifungal agent, 0.1 part of trace element additive, and 0.1 part of multivitamin.

[0070] Wherein trace element additive and multivitamin are identical with by embodiment 1.

[0071] In the feed raw material of this embodiment, the ratio of neutral detergent fiber to starch is 0.95.

[0072] Preparation method: crush corn, sieve with double-layer initial clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com