Method for preparing lithium ion battery employing organic-inorganic composite gel polymer electrolyte

A lithium-ion battery and composite gel technology, applied in the field of lithium-ion battery preparation, can solve problems such as insufficient contact, large internal resistance, explosion, etc., to reduce interface impedance, improve affinity, and improve compatibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

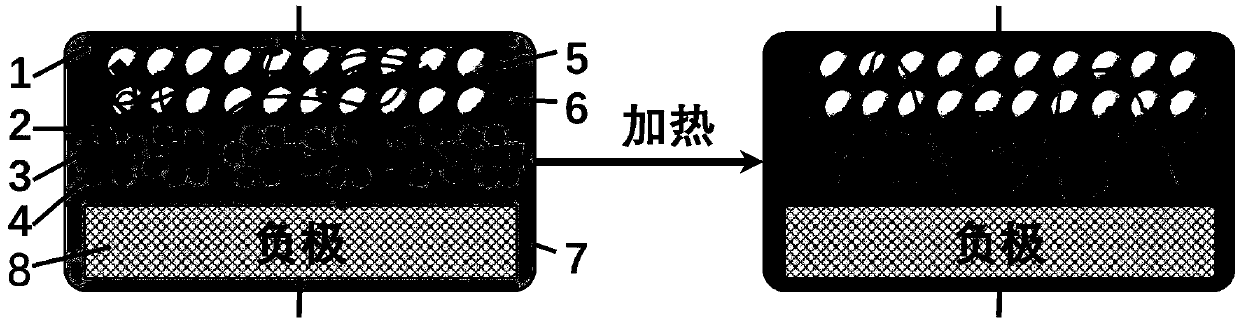

[0030] In this example, see figure 1 , a preparation method of a lithium ion battery using an organic-inorganic composite gel polymer electrolyte, comprising the steps of:

[0031] The ethylene separator was modified with 3-methacryloxypropyltrimethoxysilane functionalized silica nanoparticles, and the surface-functionalized inorganic oxide nanoparticles 4 were uniformly immobilized on the surface of the separator 3 and its internal pores. The separator 3 is modified; then the modified separator 3 is cut to the size required for the preparation of the target lithium ion battery, and the cut and modified separator 3 is sandwiched between the lithium cobaltate positive electrode 1 and the metal lithium negative electrode material 8 for setting , put it into the battery outer packaging 7 after being stacked; then inject the initiator group containing functionalized oligomer component 2, namely polyethylene glycol dimethacrylate and azobisisoheptanonitrile, into the electrolyte ca...

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1, especially in that:

[0048] In this embodiment, a method for preparing a lithium-ion battery using an organic-inorganic composite gel polymer electrolyte includes the following steps:

[0049] The polyethylene-polypropylene-polyethylene composite separator is modified with vinyltriethoxysilane functionalized zirconia nanoparticles, and the surface-functionalized inorganic oxide nanoparticles 4 are uniformly fixed on the surface of the separator 3 and its internal pores , modify the separator 3; then cut the modified separator 3 to the size required for the preparation of the target lithium-ion battery, sandwich the trimmed modified separator 3 between the lithium iron phosphate positive electrode 1 and the graphite negative electrode material 8 After being stacked, put them into the battery outer packaging 7; then inject the functionalized oligomer component 2, namely ethoxylated trimethylolpropane triallyl ether a...

Embodiment 3

[0056] This embodiment is basically the same as the previous embodiment, and the special features are:

[0057] In this embodiment, a method for preparing a lithium-ion battery using an organic-inorganic composite gel polymer electrolyte includes the following steps:

[0058] The cellulose separator was modified with titanium dioxide nanoparticles functionalized with 3-methacryloyloxypropyltris(2-methoxyethoxy)silane, and the surface-functionalized inorganic oxide nanoparticles 4 were uniformly immobilized on the surface of the separator 3 and its internal pores, the diaphragm 3 is modified; then the modified diaphragm 3 is cut into the size required for the preparation of the target lithium ion battery, and the trimmed modified diaphragm 3 is sandwiched between the ternary lithium positive electrode 1 and carbon silicon Set between the composite negative electrode materials 8, put them into the battery outer packaging 7 after being stacked; then inject the functionalized olig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com