Indium phosphide quantum dot with core-shell structure as well as preparation method and application thereof

A core-shell structure, indium quantum technology, applied in the field of fluorescent materials, can solve the problems of large lattice mismatch, difficult to widely use, low quantum efficiency, etc., and achieve wide band gap, high application potential, and quantum yield improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

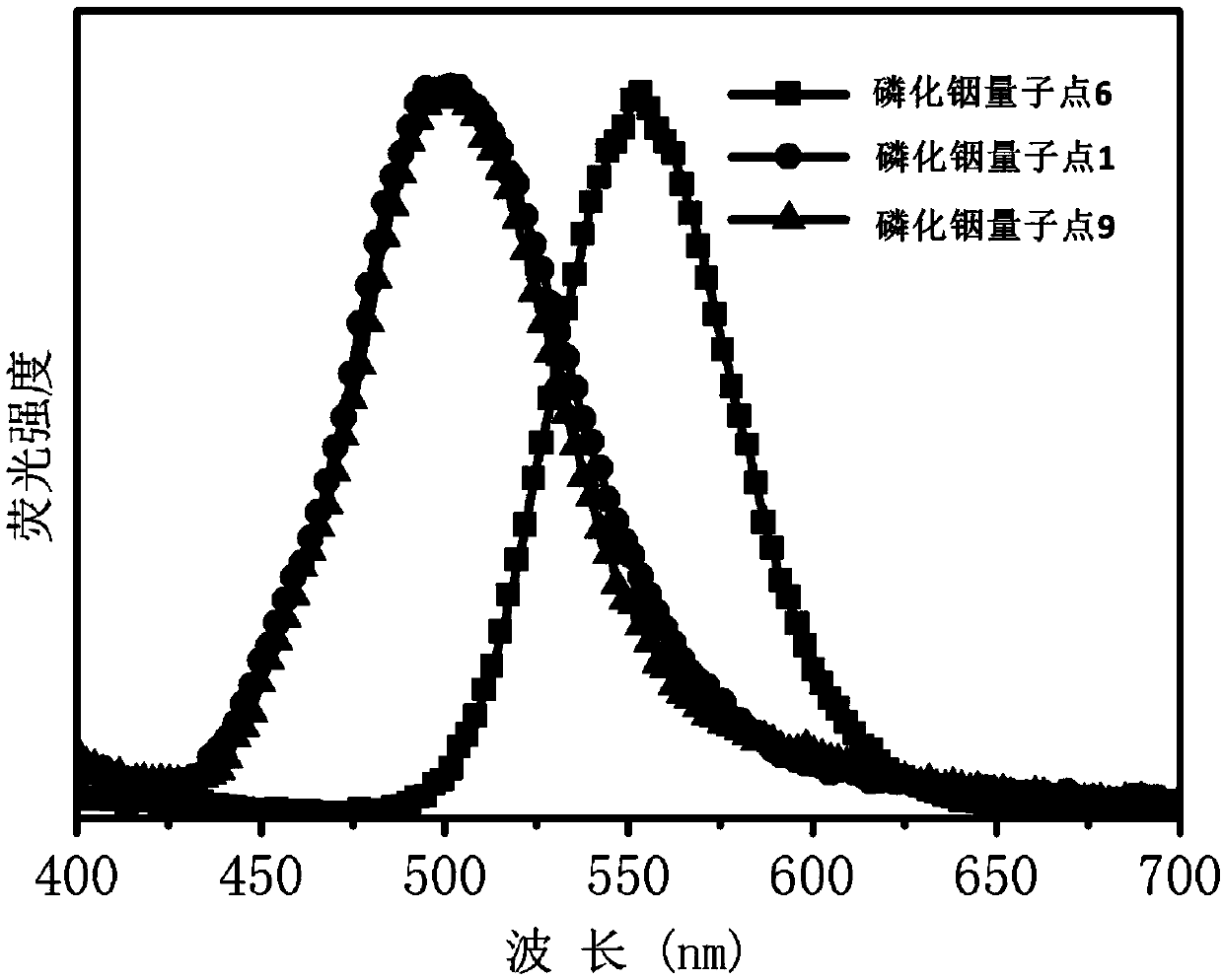

[0047] Indium phosphide quantum dots 1 were prepared by the following steps:

[0048] Step (1), dissolve 0.34mmol indium tribromide in 5mL oleylamine, add 2.2mmol zinc bromide to it, and use an air pump to pump air so that the internal pressure of the above reaction system is 3 P) and 1mL oleylamine, carry out substitution reaction at 200°C for 45min to obtain a solution of indium phosphide quantum dot core;

[0049] Step (2), add 2.2mmol manganese dichloride to the solution of the indium phosphide quantum dot core obtained in step (1), perform a pre-doping reaction at 200°C for 10min, and then add 1mL sulfur source to the reaction system Dodecanethiol and zinc source carry out solvothermal reaction, described zinc source is the mixture of 1.5g zinc stearate and 6mL 1-octadecene, the reaction temperature of solvothermal reaction is 300 ℃, and reaction time is 45min, solvothermal reaction After the reaction, the reaction product was dialyzed and separated to obtain the indium p...

Embodiment 2

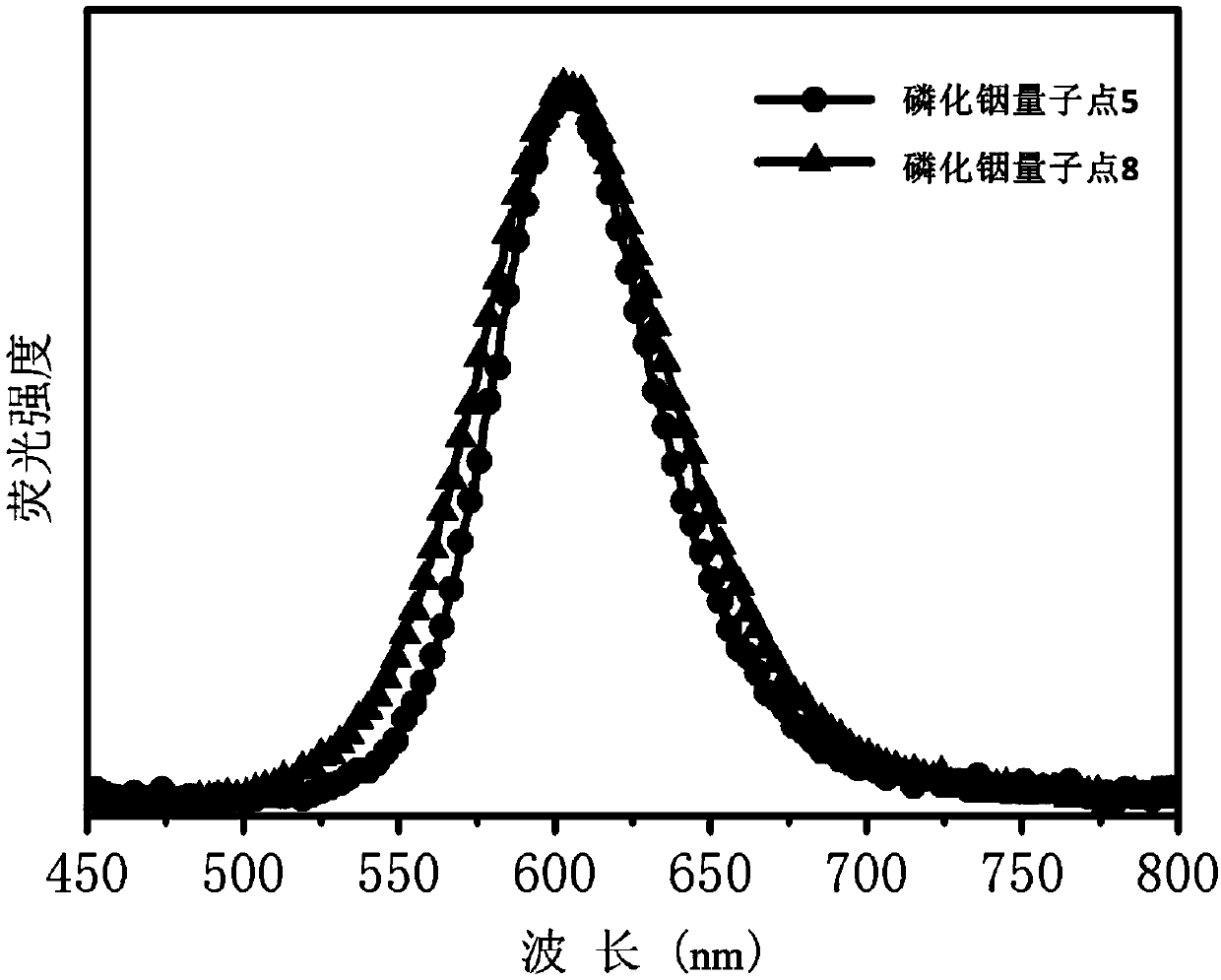

[0051] Indium phosphide quantum dots 2 were prepared by the following steps:

[0052] The only difference from Example 1 is that the temperature of the pre-doping reaction in step (2) is 100° C., and the reaction time is 20 minutes; the temperature of the solvothermal reaction is 100° C., and the reaction time is 60 minutes.

[0053] In Example 2, indium phosphide quantum dots 2 were obtained. The quantum yield of indium phosphide quantum dots 2 was 82%, and the molar ratio of zinc sulfide to heteroatoms was 10-100:1.

Embodiment 3

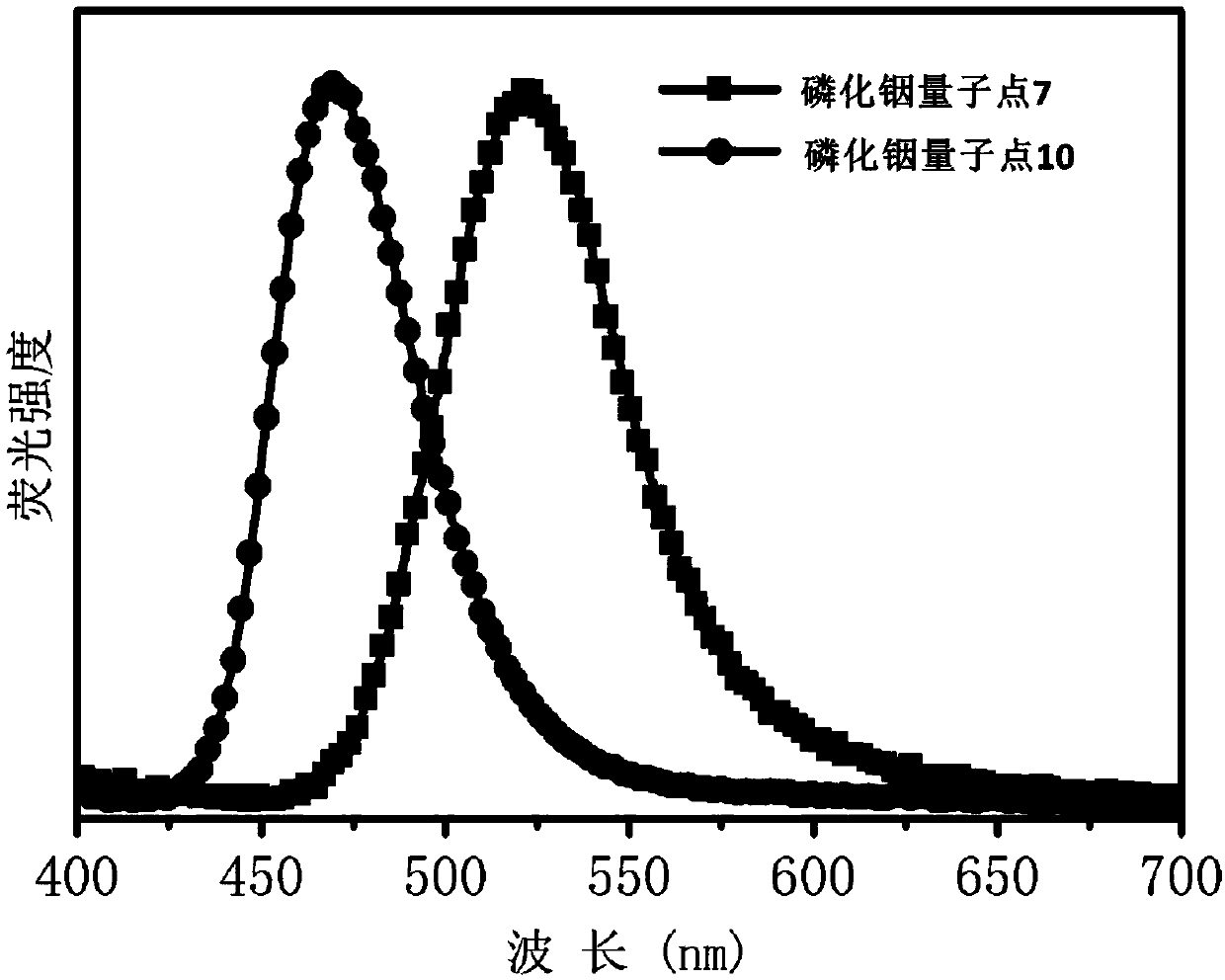

[0055] Indium phosphide quantum dots 3 were prepared by the following steps:

[0056] The only difference from Example 1 is that the temperature of the pre-doping reaction in step (2) is 300° C., the reaction time is 5 minutes, and the temperature of the solvothermal reaction is 300° C., and the reaction time is 30 minutes.

[0057] In Example 3, indium phosphide quantum dots 3 were obtained. The quantum yield of indium phosphide quantum dots 3 was 88%, and the molar ratio of zinc sulfide to heteroatoms was 10-100:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com