Flame-retardant polymer solid electrolyte material and electrolyte membrane and application thereof

A solid electrolyte membrane, flame retardant polymer technology, used in circuits, electrical components, secondary batteries, etc., can solve the problems of reduced lithium ion conductivity, environmental and construction personnel damage, and electrolyte membrane brittleness. The effect of improving flame retardancy, ensuring safety, and improving ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A flame-retardant polymer solid electrolyte material, comprising: 60% flame-retardant water-based polyurethane, 35% lithium trifluoromethanesulfonate and 5% nano-α-alumina; the flame-retardant polymer solid electrolyte material is prepared When forming an electrolyte membrane, it includes: stirring the flame-retardant water-based polyurethane and nano-α-alumina according to the above weight percentage to obtain a mixed solution, adding lithium trifluoromethanesulfonate to the mixed solution, stirring evenly to obtain a casting solution, and mixing the The casting solution is cast in a mold, and dried at 40° C. for 48 hours in a vacuum state to obtain the electrolyte membrane;

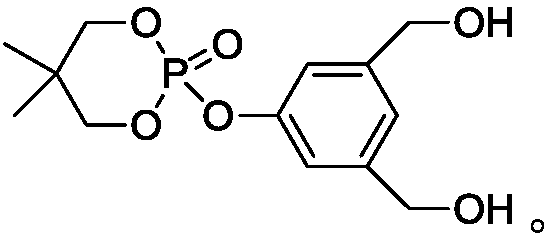

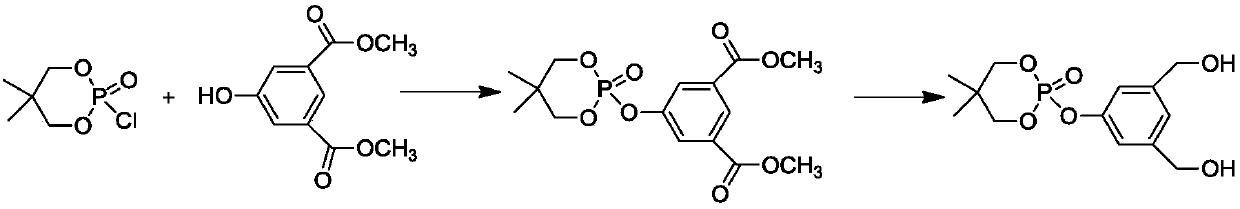

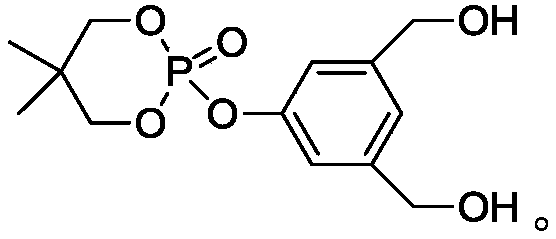

[0026] Wherein, the flame-retardant water-based polyurethane is synthesized by the following method: mix 35 parts of polyadipate-1,4-butylene glycol ester diol and 40 parts of isophorone diisocyanate in parts by weight, and mix them at 80° C. Lower the prepolymerization reaction for 2 hours, then...

Embodiment 2

[0029]A flame-retardant polymer solid electrolyte material, comprising: flame-retardant water-based polyurethane 80%, bistrifluoromethanesulfonimide lithium 15% and nanometer α-alumina 5%; the flame-retardant polymer solid When the electrolyte material is prepared into an electrolyte membrane, it includes: stirring the flame-retardant water-based polyurethane and nano-α-alumina according to the above weight percentage to obtain a mixed solution, adding lithium bistrifluoromethylsulfonimide to the mixed solution, and stirring evenly to obtain Casting solution, casting the casting solution in a mold, drying at 100°C for 12 hours in a vacuum state, to obtain the electrolyte membrane;

[0030] The flame-retardant water-based polyurethane is synthesized by the following method: mix polycaprolactone diol, 65 parts, and hexamethylene diisocyanate 10 parts by weight, prepolymerize at 90°C for 1 hour, and then add two 10 parts of hydroxymethyl butyric acid, 6 parts of 1,4-butanediol, 2...

Embodiment 3

[0033] A flame-retardant polymer solid electrolyte material, comprising: 70% flame-retardant water-based polyurethane, 29% lithium bisfluorosulfonimide and 1% nano-α-alumina by weight percentage; the flame-retardant polymer solid electrolyte material is prepared Forming the electrolyte membrane includes: stirring the flame-retardant water-based polyurethane and nano-α-alumina according to the above weight percentage to obtain a mixed solution, adding lithium bisfluorosulfonyl imide to the mixed solution, stirring evenly to obtain a casting solution, and mixing the The casting solution is cast in a mold, and dried at 60° C. for 20 hours in a vacuum state to obtain the electrolyte membrane;

[0034] Wherein, the flame-retardant water-based polyurethane is synthesized by the following method: mix 50 parts of polycarbonate diol and 25 parts of toluene diisocyanate in parts by weight, prepolymerize at 85°C for 1.5 hours, and then add dimethylol 6 parts of propionic acid, 9 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com