A kind of gas phase arsenic removal agent and preparation method thereof

A technology of arsenic removal and gas phase, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, and can solve problems such as complex preparation process, small arsenic capacity, and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

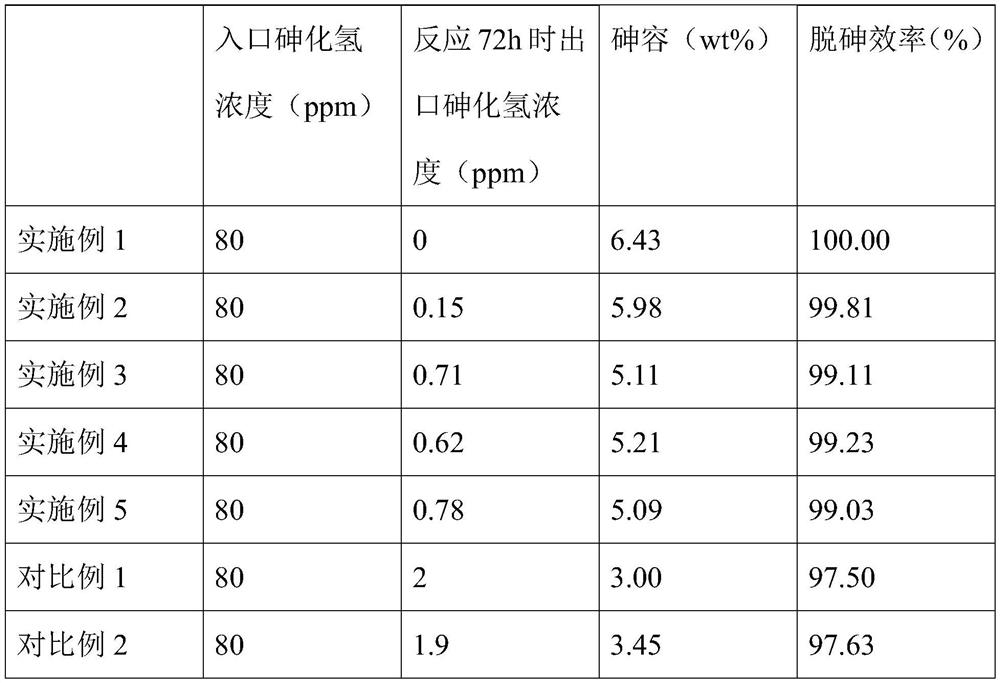

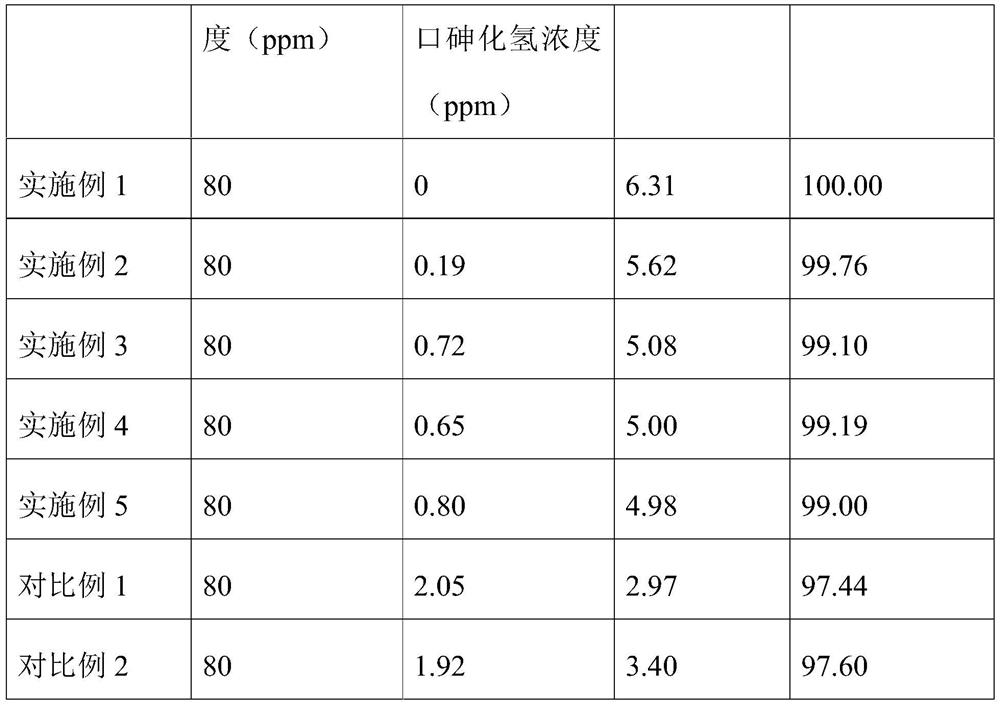

Examples

Embodiment 1

[0040] This embodiment provides a gas-phase arsenic removal agent and its preparation method. The gas-phase arsenic removal agent has a specific surface area of 500m 2 / g of 13X molecular sieve, penetrating agent-EDTA, oxidant-potassium permanganate, γ-alumina powder and binder-cellulose powder are prepared as raw materials, wherein, EDTA 1g, potassium permanganate 1g, 13X molecular sieve 0.67g, γ-alumina powder 2.67g, cellulose powder 0.28g.

[0041] The preparation method of the above gas-phase arsenic removal agent comprises the following steps:

[0042] S1, the specific surface area is 500m 2 The 13X molecular sieve per g is impregnated in the mixed aqueous solution containing EDTA and potassium permanganate, in terms of mass percentage, in the mixed aqueous solution, the EDTA content is 1wt%, the potassium permanganate content is 1wt%, the immersion time is 12h, and then at 90 Under the temperature of ℃, dry for 10h to obtain the precursor sample;

[0043] S2. Dry-mi...

Embodiment 2

[0045] This embodiment provides a gas-phase arsenic removal agent and its preparation method. The gas-phase arsenic removal agent has a specific surface area of 400m 2 / g sodium Y molecular sieve, penetrating agent-mass concentration of 25% ammonia, oxidant-nickel oxide, β-alumina powder and binder-water are prepared from raw materials, wherein the mass concentration is 25% of ammonia 1g, 4g of nickelous oxide, 5g of sodium Y molecular sieve, 30g of β-alumina powder, and 0.40g of water.

[0046] The preparation method of the above gas-phase arsenic removal agent comprises the following steps:

[0047] S1, set the specific surface area to 400m 2 The sodium Y molecular sieve per g is impregnated in the mixed aqueous solution containing ammoniacal liquor and nickelous oxide with a mass concentration of 25%. In terms of mass percentage, in the mixed aqueous solution, the ammoniacal liquor content is 1wt%, and the nickelous oxide content is 4wt%, and the immersion time is 1h, t...

Embodiment 3

[0050] This embodiment provides a gas-phase arsenic removal agent and its preparation method, the gas-phase arsenic removal agent has a specific surface area of 300m 2 / g of calcium Y molecular sieve, penetrating agent-acetic acid, oxidant-ferric chloride, γ-alumina powder and binder-silica sol are prepared as raw materials, wherein, acetic acid 1g, ferric chloride 7g, calcium Y molecular sieve 1.6 g, gamma-alumina powder 48g, silica sol 6.4g.

[0051] The preparation method of the above gas-phase arsenic removal agent comprises the following steps:

[0052] S1, set the specific surface area to 300m 2 Calcium Y molecular sieve per g is impregnated in the mixed aqueous solution containing acetic acid and ferric chloride, in terms of mass percentage, the acetic acid content in the mixed aqueous solution is 1wt%, the ferric chloride content is 7wt%, the immersion time is 6h, and then at 120 ℃ Under the temperature, dry 5h, obtain precursor sample;

[0053] S2. Dry-mix the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com