Method for treating organic pollutants and photocatalytic sterilization by using modified carbon quantum dot loaded hollow tubular carbon nitride photocatalyst

A technology of organic pollutants and carbon quantum dots, applied in chemical instruments and methods, physical/chemical process catalysts, water pollutants, etc., can solve problems such as adverse environmental effects, low photocatalytic activity, and poor light absorption ability, and achieve high Application value and commercial value, high photocatalytic efficiency, good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method for treating organic pollutants by using a modified carbon quantum dot-loaded hollow tubular carbon nitride photocatalyst, specifically using a modified carbon quantum dot-loaded hollow tubular carbon nitride photocatalyst to treat tetracycline wastewater, comprising the following steps:

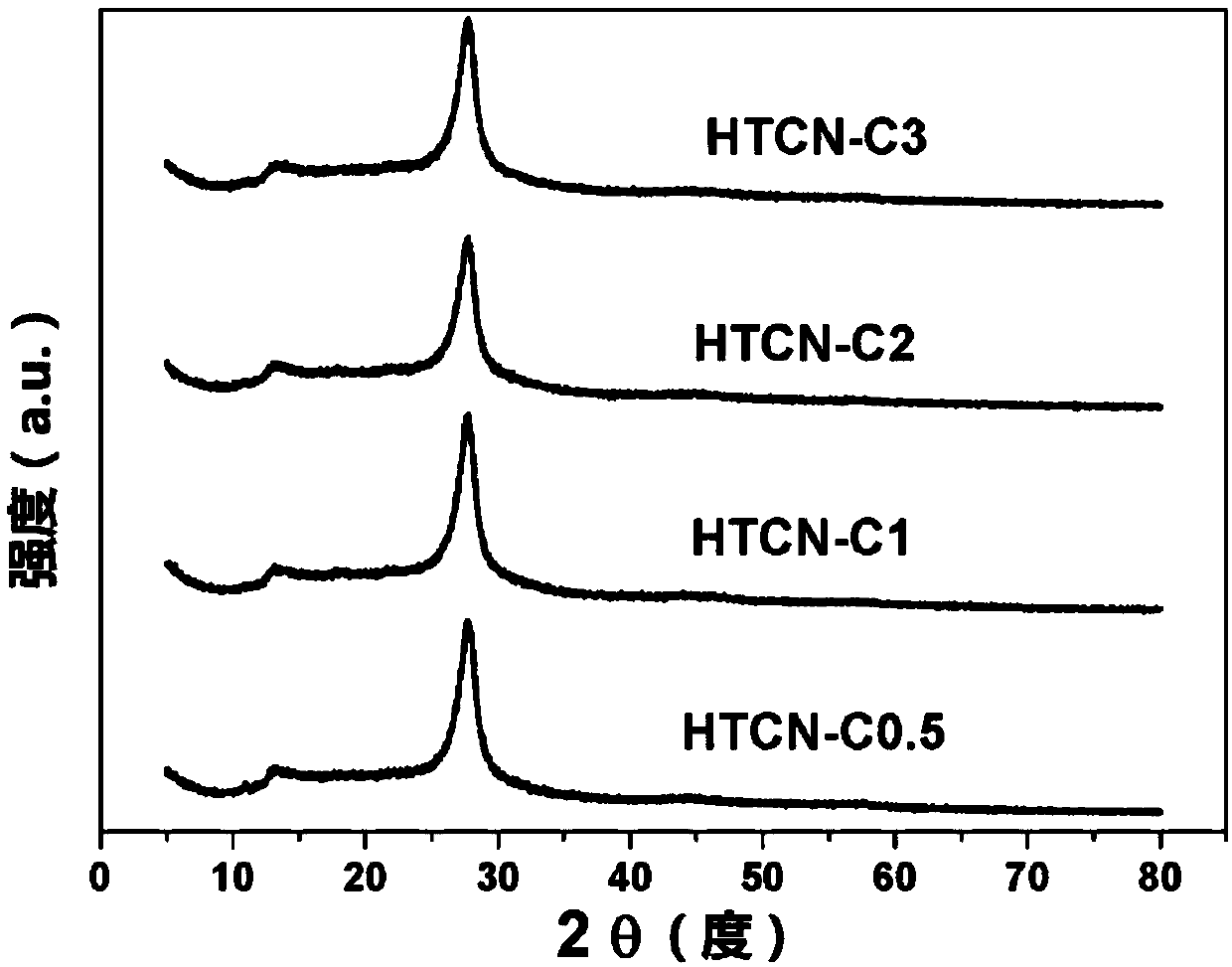

[0058] Weigh modified carbon quantum dot-supported hollow tubular carbon nitride photocatalysts (HTCN-C0.5, HTCN-C1, HTCN-C2, HTCN-C3), each 30mg, add to 30mL tetracycline with a concentration of 20mg / L In the wastewater, stir magnetically for 1 hour in the dark at a rotational speed of 400 r / min. After reaching adsorption equilibrium, turn on the light source (300W xenon lamp), and perform photocatalytic reaction under simulated sunlight for 1 hour to complete the degradation of tetracycline.

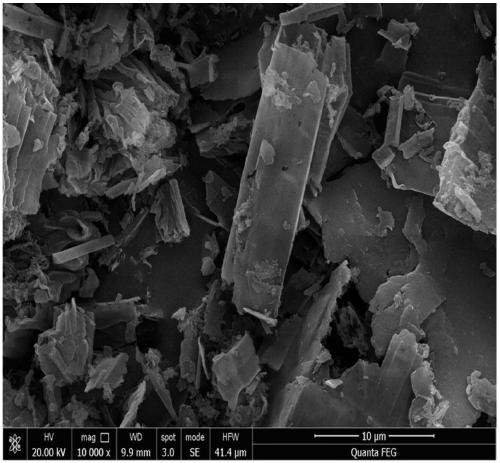

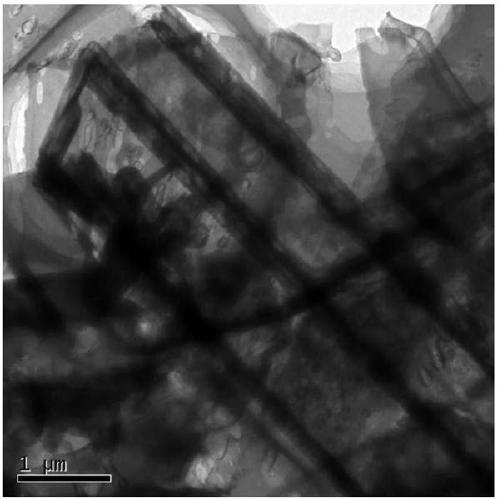

[0059] In this example, the modified carbon quantum dot-supported hollow tubular carbon nitride photocatalyst (HTCN-C0.5) was used as a carrier, and the hollow tubular carbon nitride w...

Embodiment 3

[0080] A method for photocatalytic sterilization of bacteria using a modified carbon quantum dot-loaded hollow tubular carbon nitride photocatalyst, specifically treating Escherichia coli with a modified carbon quantum dot-loaded hollow tubular carbon nitride photocatalyst, comprising the following steps:

[0081] Weigh 30 mg of the modified carbon quantum dot-loaded hollow tubular carbon nitride photocatalyst (HTCN-C2) prepared in Example 1, add it to 49.5 mL of sterile water, add 0.5 mL, the concentration is 30 mL, and the concentration is 3× 10 9 CFU / mL E. coli solution, at this time the concentration of E. coli in the system was diluted to 3×10 7 CFU / mL, turn on the light source (300W xenon lamp), irradiate under simulated sunlight to carry out photocatalytic sterilization reaction for 1 hour, and complete the inactivation of Escherichia coli.

[0082] Take 100uL of reaction liquid every 15 minutes, then dilute these bacterial liquids appropriately, and finally use the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com