All-solid-state organic electrochemical phototransistor and preparation method thereof

A phototransistor and all-solid-state technology, which is applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, circuits, etc., can solve problems such as difficult integration of electronic devices, volatile liquid electrolytes, and unstable device performance, achieving significant economic and Social benefits, beneficial to popularization and application, excellent photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

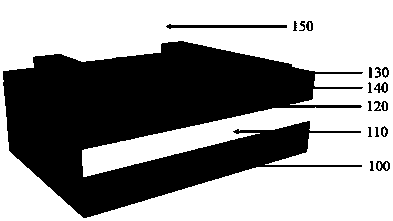

[0025] 1) Wash the cut 1.5cm×1.5cm heavily doped P-type silicon wafer with acetone, isopropanol, chloroform, and distilled water (three times), and dry it with nitrogen to obtain a clean silicon wafer Make the base.

[0026] 2) Preparation of ion gel electrolyte: polyacrylonitrile, lithium bistrifluoromethanesulfonimide, ethylene carbonate and propylene carbonate were mixed in a mass ratio of 14.1:3.9:41:41 and heated in a 90°C water bath. Stir until clear, transparent colloidal gel state;

[0027] 3) Use a syringe to cover the silicon wafer with the electrolyte gel prepared in step 2), and then use a low speed of 500rpm (5s) and a high speed of 3500rpm (45s) to spin the solution to form a uniform film on the silicon wafer, and then place the silicon wafer Move it into a vacuum drying oven at 120°C for annealing for 10 hours to form a 2 μm electrolyte layer.

[0028] 4) Spin-coat the dispersion of PEDOT:PSS at 1000rpm (60s) to prepare the active layer, and then anneal at 120...

Embodiment 2

[0032] 1) Wash the cut 1.5cm×1.5cm heavily doped P-type silicon wafer with acetone, isopropanol, chloroform, and distilled water (three times), and dry it with nitrogen to obtain a clean silicon wafer Make the base.

[0033] 2) Preparation of ion gel electrolyte: polyacrylonitrile, lithium bistrifluoromethanesulfonimide, ethylene carbonate and propylene carbonate were mixed in a mass ratio of 14.1:3.9:41:41 and heated in a 90°C water bath. Stir until clear, transparent colloidal gel state;

[0034] 3) Use a syringe to spread the electrolyte prepared in step 2) on the edge of the junction between the scraper and the silicon wafer. The distance between the scraper and the silicon substrate is 200 μm, and the scraping speed is 20 mm / s. After forming a uniform film, move it into a vacuum drying oven for annealing at 120 ° C for 10 h .

[0035] 4) On the basis of step 3), spread the PEDOT:PSS dispersion on the edge of the junction between the scraper and the silicon wafer. The di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com