Method for chemically plating copper on carbon fiber surface by utilizing sodium hypophosphite as reducing agent

A technology of sodium hypophosphite and surface chemistry, which is applied in the direction of liquid chemical plating, metal material coating technology, coating, etc., can solve problems such as environmental pollution, human hazards, toxicity, etc., and achieve increased surface roughness, plating solution Stabilization, effect of increased deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

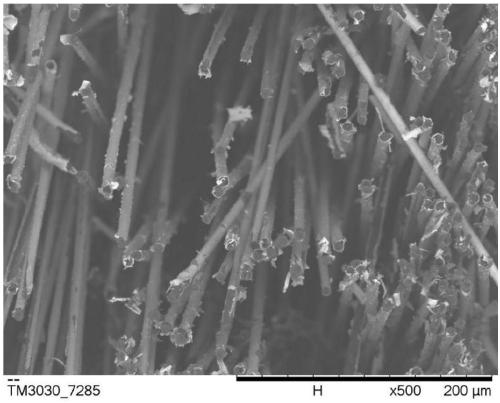

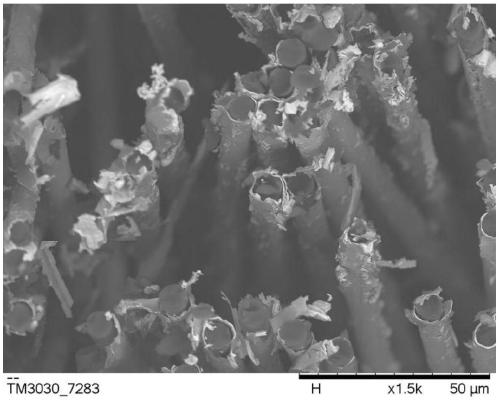

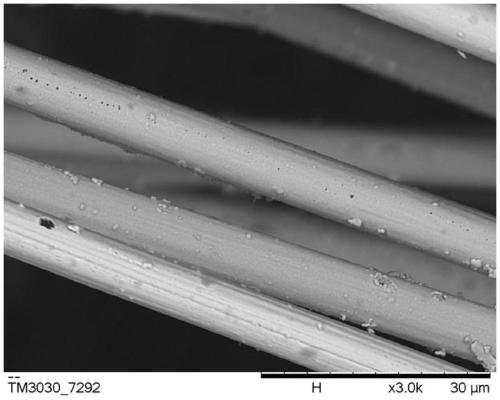

Image

Examples

Embodiment 1

[0038] A kind of method utilizing sodium hypophosphite to do reducing agent carbon fiber surface electroless copper plating, comprises the following steps:

[0039] (1) Pretreatment: carbon fiber pretreatment is followed by degreasing treatment, coarsening treatment, neutralization treatment, sensitization treatment, activation treatment and reduction treatment; degreasing treatment: sodium hydroxide 10g / L, sodium carbonate 15g / L, Sodium phosphate 15g / L; roughening treatment: potassium dichromate 10g / L; neutralization treatment: sodium hydroxide 8g / L; sensitization treatment: stannous chloride 20g / L; activation treatment: palladium chloride 0.2g / L L; reduction treatment: sodium hypophosphite 5g / L; preferably, 8ml / L concentrated sulfuric acid needs to be added for roughening treatment; 40ml / L concentrated hydrochloric acid needs to be added for sensitization treatment; 8ml / L concentrated hydrochloric acid needs to be added for activation treatment . The temperature of degreasi...

Embodiment 2

[0044] A kind of method utilizing sodium hypophosphite to do reducing agent carbon fiber surface electroless copper plating, comprises the following steps:

[0045] (1) Pretreatment: Carbon fiber pretreatment is followed by degreasing treatment, coarsening treatment, neutralization treatment, sensitization treatment, activation treatment and reduction treatment; degreasing treatment: sodium hydroxide 30g / L, sodium carbonate 30g / L, Sodium phosphate 30g / L; coarsening treatment: potassium dichromate 30g / L; neutralization treatment: sodium hydroxide 15g / L; sensitization treatment: stannous chloride 25g / L; activation treatment: palladium chloride 0.5g / L L; reduction treatment: sodium hypophosphite 20g / L; preferably, 12ml / L concentrated sulfuric acid needs to be added for roughening treatment; 50ml / L concentrated hydrochloric acid needs to be added for sensitization treatment; 12ml / L concentrated hydrochloric acid needs to be added for activation treatment . The temperature of degr...

Embodiment 3

[0050] A kind of method utilizing sodium hypophosphite to do reducing agent carbon fiber surface electroless copper plating, comprises the following steps:

[0051] (1) Pretreatment: carbon fiber pretreatment is followed by degreasing treatment, coarsening treatment, neutralization treatment, sensitization treatment, activation treatment and reduction treatment; degreasing treatment: sodium hydroxide 20g / L, sodium carbonate 22g / L, Sodium phosphate 23g / L; coarsening treatment: potassium dichromate 20g / L; neutralization treatment: sodium hydroxide 10g / L; sensitization treatment: stannous chloride 22g / L; activation treatment: palladium chloride 0.3g / L L; reduction treatment: sodium hypophosphite 12g / L; preferably, 10ml / L concentrated sulfuric acid needs to be added for roughening treatment; 45ml / L concentrated hydrochloric acid needs to be added for sensitization treatment; 10ml / L concentrated hydrochloric acid needs to be added for activation treatment . The temperature of degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com