Catalytic ozonation catalyst and method of using same for treating biochemical waste gas

A technology of ozone catalytic oxidation and catalyst, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. Complexity and other problems, to achieve the effect of simple and easy operation, realization of recycling, and high degree of technical integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

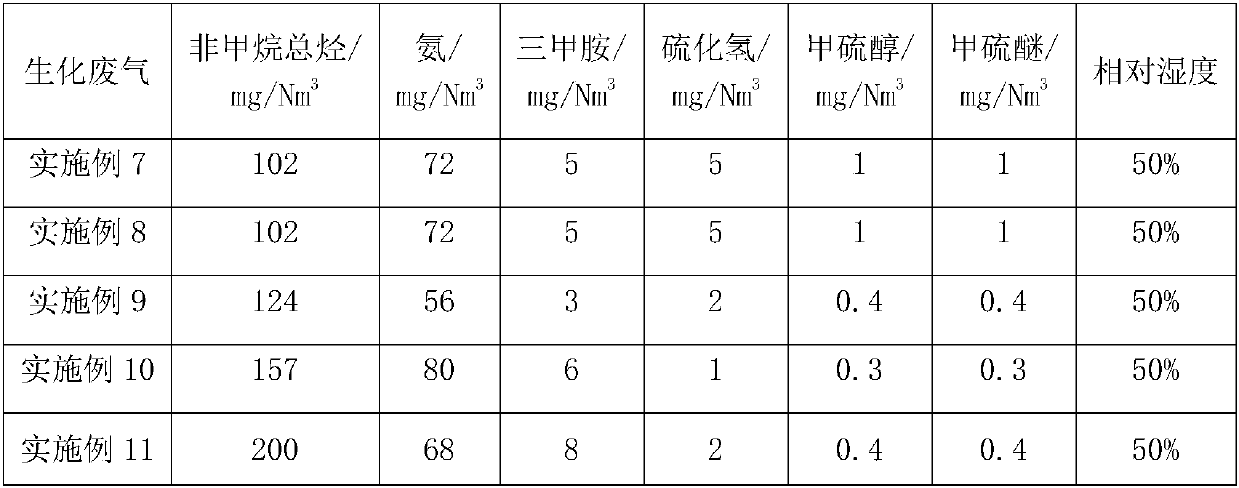

Examples

Embodiment 1

[0054] Example 1: Preparation of plasma modified struvite and dried sludge

[0055] Take 20g of struvite and dried sludge mixed at a ratio of 1:1 and place it in 200mL of pure water, then slowly pour it into the plasma reactor, vacuumize the reactor, and then turn on the power to discharge. The voltage is 16kV, and the discharge frequency is 100Hz. After reacting for 10 minutes, the struvite and dried sludge mixture was taken out, rinsed with pure water and then dried to obtain plasma-modified struvite and dried sludge.

Embodiment 2

[0056] Embodiment 2: the preparation of 0# catalyst

[0057] Take 20g of struvite and dried sludge mixed at a ratio of 1:1 and place it in a dipping bottle for vacuum pretreatment. The vacuum pretreatment time is 20min and the vacuum degree is 96.0KPa; Cobalt nitrate aqueous solution 6.0mL, nickel nitrate aqueous solution 2.7mL containing nickel 0.15g / mL, manganese nitrate aqueous solution 3.0mL, cerium nitrate aqueous solution 2.7mL containing cerium 0.15g / mL, neodymium 0.10g / mL Add 2.0 mL of neodymium nitrate aqueous solution to 10 wt % ethanol aqueous solution to prepare an impregnating solution with a total volume of 16.4 mL. Add the above impregnation solution into the vacuum impregnation bottle with the above struvite and dried sludge carrier and mix evenly, impregnate the above struvite and dried sludge carrier with equal volume, after immersion for 60min, take it out and put it in the oven Dry at 120°C for 3 hours, and then bake at 500°C for 3 hours in a muffle furnac...

Embodiment 3

[0059] Embodiment 3: the preparation of 1# catalyst

[0060] Take struvite and dried sludge 20g after plasma modification in Example 1 and place them in a dipping bottle for vacuum pretreatment. The vacuum pretreatment time is 20min, and the vacuum degree is 96.0Kpa; Cobalt nitrate aqueous solution 6.0mL, nickel nitrate aqueous solution 2.7mL containing nickel 0.15g / mL, manganese nitrate aqueous solution 3.0mL, cerium nitrate aqueous solution 2.7mL containing cerium 0.15g / mL, neodymium 0.10g Add 2.0mL of neodymium nitrate aqueous solution per mL to the ethanol aqueous solution with an ethanol concentration of 10wt%, to prepare an impregnation solution with a total volume of 16.4mL. Add the above impregnation solution into the vacuum impregnation bottle with the above struvite and dried sludge carrier and mix evenly, impregnate the above struvite and dried sludge carrier with equal volume, after immersion for 60min, take it out and put it in the oven It was dried at 120°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com