Silicon nitride, ceramic slurry and preparation method

A technology of ceramic slurry and silicon nitride, which is applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve problems such as thermal shock resistance and mechanical strength, and avoid large-area hard agglomeration. Simple and consistent particle shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

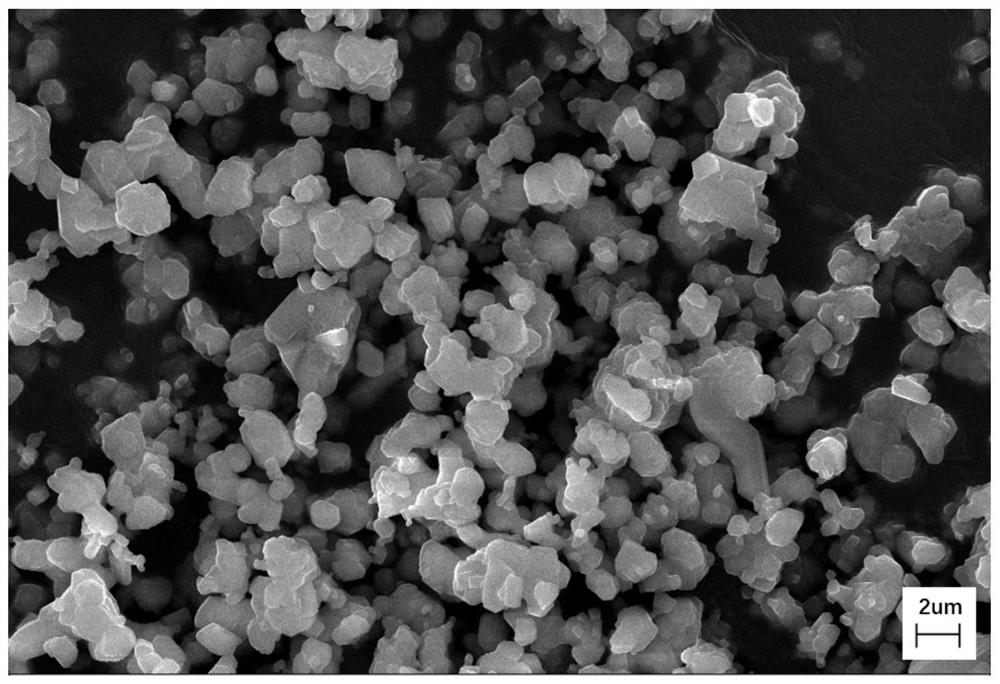

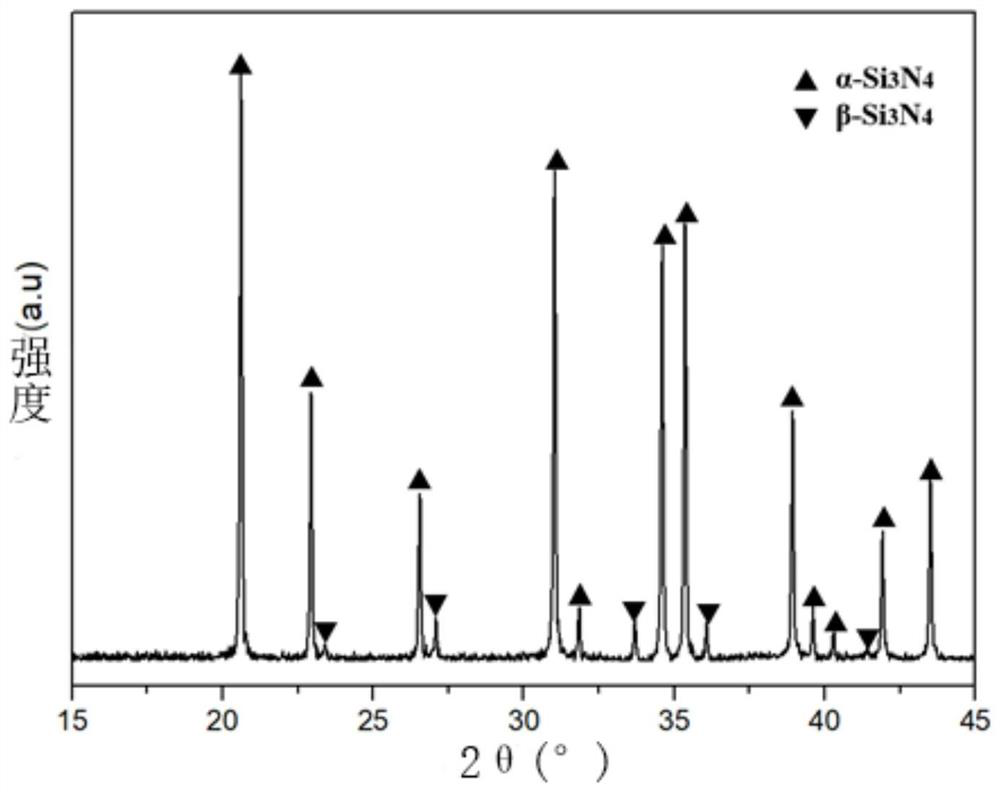

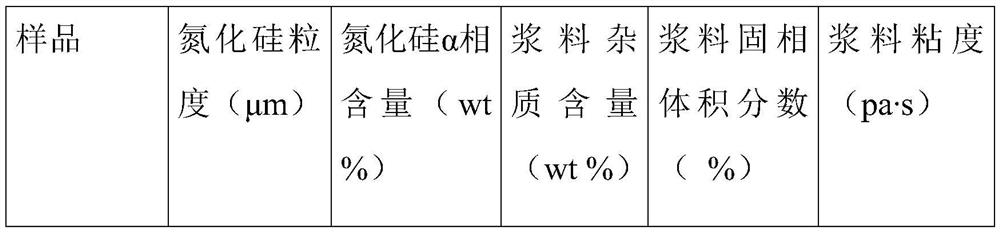

[0052] Under the nitrogen pressure of 1 MPa, the high-purity α-silicon nitride powder with a particle size of 3 μm, an α-phase content of 85%, an impurity content of 2%, and a consistent particle shape was prepared by a temperature-controlled activated combustion synthesis method. The silicon nitride powder is coarsely sieved with a 600-mesh screen, and placed in nitric acid, hydrochloric acid, sulfuric acid (the volume content ratio is respectively 20%, 60%, 20%, and the acid solution mass fraction is respectively 40%, 15%, 58% %) composition of the mixed acid was pickled for 3 hours, then washed 3 times with water, and dried by vacuum drying after suction filtration. Afterwards, place the silicon nitride powder in a heating furnace for heat treatment. The specific process is to heat treat at 600°C for 5 hours under a flowing nitrogen atmosphere, with a heating rate of 8°C / min, in which the nitrogen purity is 99.999%, and the flow rate is 3m / s . The specific surface area of ...

Embodiment 2

[0056] Under 3MPa nitrogen pressure, the high-purity α-silicon nitride powder with a particle size of 5 μm, an α-phase content of 90%, an impurity content of 1.6%, and a consistent particle shape was prepared by a temperature-controlled activated combustion synthesis method. The silicon nitride powder is coarsely sieved with a 600-mesh screen, and placed in nitric acid, hydrochloric acid, sulfuric acid (the volume content ratio is respectively 20%, 60%, 20%, and the acid solution mass fraction is respectively 40%, 15%, 58% %) of the mixed acid composition was pickled for 5 hours, then washed 5 times with water, and dried by vacuum drying after suction filtration. Afterwards, place the silicon nitride powder in a heating furnace for heat treatment. The specific process is heat treatment at 700°C for 4 hours under a flowing nitrogen atmosphere, with a heating rate of 8°C / min, in which the nitrogen purity is 99.999%, and the flow rate is 3m / s . The specific surface area of the...

Embodiment 3

[0060] Under the nitrogen pressure of 0.6MPa, the high-purity α-silicon nitride powder with particle size of 1.5μm, α-phase content of 93%, impurity content of 1.3% and consistent particle shape was prepared by temperature-controlled activated combustion synthesis method. The silicon nitride powder is coarsely sieved with a 600-mesh screen, and placed in nitric acid, hydrochloric acid, sulfuric acid (the volume content ratio is respectively 20%, 60%, 20%, and the acid solution mass fraction is respectively 40%, 15%, 58% %) of the mixed acid composition was pickled for 5 hours, then washed 5 times with water, and dried by vacuum drying after suction filtration. Afterwards, place the silicon nitride powder in a heating furnace for heat treatment. The specific process is heat treatment at 800°C for 6 hours under a flowing nitrogen atmosphere, with a heating rate of 8°C / min, in which the nitrogen purity is 99.999%, and the flow rate is 3m / s . The specific surface area of the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com