Preparation method of styrene-free unsaturated resin

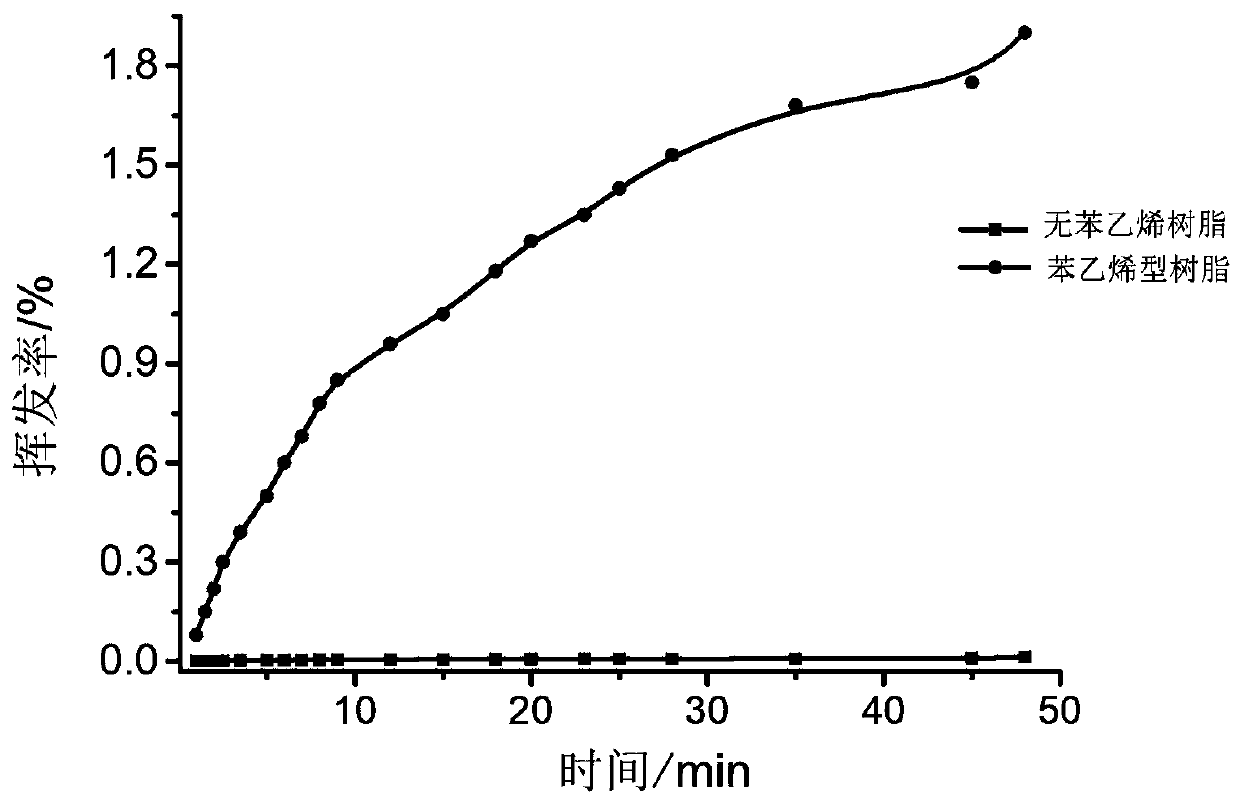

A styrene-free and unsaturated technology, applied in the field of preparation of styrene-free unsaturated resins, can solve the problems of complex components, complicated steps, high isocyanate toxicity, etc., and achieve a simple and convenient synthesis route, improved copolymerization characteristics, and moderate viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

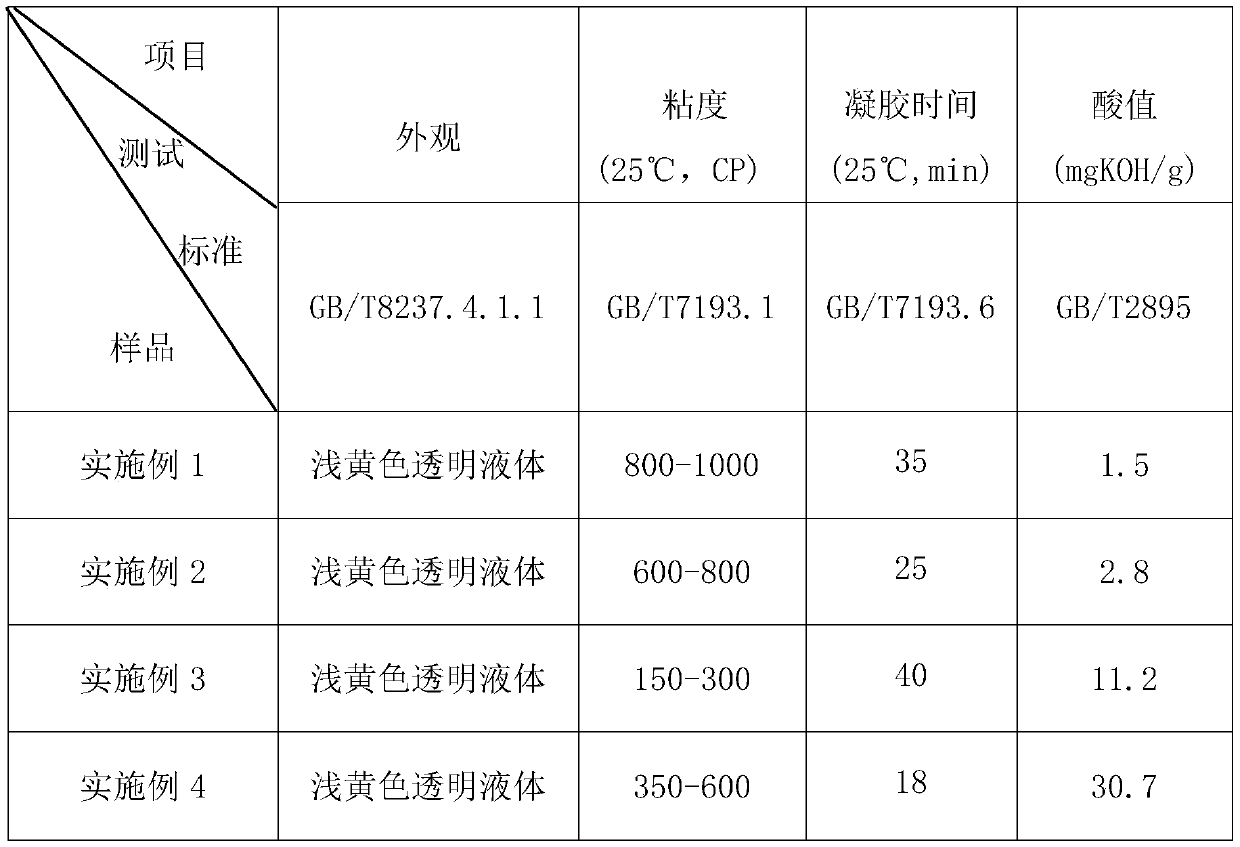

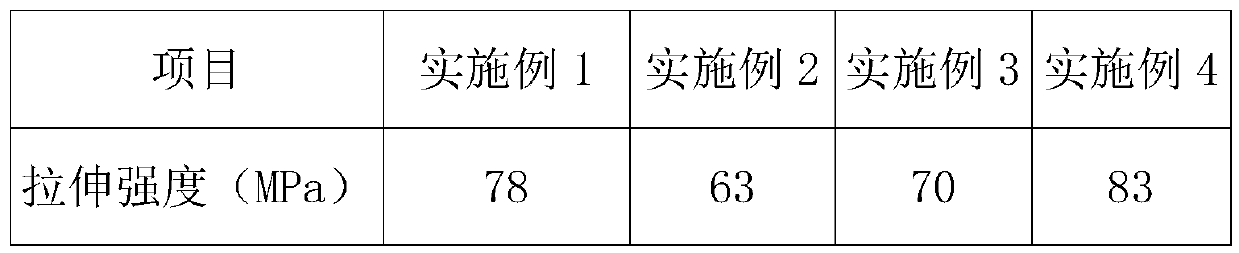

Embodiment 1

[0030] A styrene-free unsaturated resin is prepared according to the following raw material formula and preparation method.

[0031] The formula is:

[0032] specific components

Weight / g

30

20

tetrahydrophthalic anhydride

60

1-octanol

30

40

120

500

2

p-methoxyphenol

0.2

[0033] The preparation method steps are as follows:

[0034] (1) Add 1-octanol and diethylene glycol into a reaction kettle with a heating device and a stirring device, start stirring, blow nitrogen, slowly heat up to 80-85°C, add phthalic anhydride, isophthalic acid, tetrahydro Phthalic anhydride, gradually increase the temperature to 210-215°C, and react until the acid value is 85-90mgKOH / g.

[0035](2) After the above reaction is completed, adjust the temperature of ...

Embodiment 2

[0038] A styrene-free unsaturated resin is prepared according to the following raw material formula and preparation method.

[0039] The formula is:

[0040] specific components

Weight / g

80

40

Trimethylolpropane diallyl ether

80

1,4-Butanediol

60

60

Tripropylene glycol diacrylate

260

220

1.8

Methylhydroquinone

0.3

copper naphthenate

0.1

[0041] The preparation method steps are as follows:

[0042] (1) Add trimethylolpropane diallyl ether and 1,4-butanediol into a reaction kettle with a heating device and a stirring device, start stirring, blow nitrogen, and slowly heat up to 80-85°C, Add maleic anhydride and benzoic acid, gradually raise the temperature to 160-170°C, and react until the acid value is 52-60mgKOH / g.

[0043] (2) After the above reaction is co...

Embodiment 3

[0046] A styrene-free unsaturated resin is prepared according to the following raw material formula and preparation method.

[0047] The formula is:

[0048] specific components

Weight / g

160

Ethylene glycol monoallyl ether

80

10

10

140

Glycerol formal methyl acrylate

200

200

2.0

p-tert-butylcatechol

0.1

2,6-di-tert-butyl-p-methylphenol

0.2

[0049] The preparation method steps are as follows:

[0050] (1) Add ethylene glycol monoallyl ether, propylene glycol and neopentyl glycol into a reaction kettle with a heating device and a stirring device, start stirring, blow nitrogen, slowly heat up to 80-85°C, add phthalic anhydride, Gradually raise the temperature to 160-170°C, and react until the acid value is 205-210mgKOH / g.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com