A kind of organic-inorganic composite lithium single-ion conductive material and preparation method

A conductive material, single-ion technology, used in circuits, electrical components, battery electrodes, etc., can solve problems such as failure to meet the requirements of high-performance lithium-ion batteries and low room temperature conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

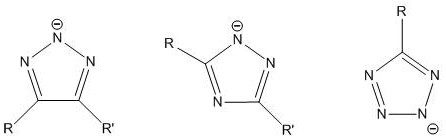

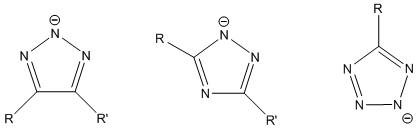

Image

Examples

Embodiment 1

[0017] (1) Take 0.91g lithium aminotetrazolium salt, disperse it in 50mL DMSO, add an equimolar amount of IPDI diisocyanate (2.22g) dropwise at room temperature, stir until the emulsion becomes clear and set aside;

[0018] (2) Take 6.0 g of polyethylene glycol (PEG600) in a single-necked bottle, add an equimolar amount of triethoxysilyl propyl isocyanate (2.5 g) dropwise under stirring at 80°C, and stir for 4 hours to obtain a uniform transparent solution spare;

[0019] (3) Add the solution obtained in step (1) dropwise into the solution obtained in step (2) under stirring, and after reacting for 12 hours, add 0.1wt.% of H 2 O, after mixing evenly, apply a film; after the solvent is evaporated to dryness at 60°C, continue to dry at 80°C for 24 hours to obtain a solid film. The room temperature conductivity of the solid film is 1.5×10 -5 S cm -1 , the electrochemical window is 4.7V (for Li / Li + ), the lithium ion migration number is 0.89.

Embodiment 2

[0021] (1) Take 0.91g lithium aminotetrazolium salt, disperse it in 50mL DMSO, add an equimolar amount of IPDI diisocyanate (2.22g) dropwise at room temperature, stir until the emulsion becomes clear and set aside;

[0022] (2) Take 8.0 g of polyethylene glycol (PEG800) in a single-necked bottle, add dropwise an equimolar amount of triethoxysilyl propyl isocyanate (2.5 g) under stirring at 80°C, and stir for 6 hours to obtain a uniform and transparent The solution is ready for use;

[0023] (3) Add the solution obtained in step (1) dropwise to the solution obtained in step (2) while stirring, and after reacting for 12 hours, add 0.1wt.% of H 2 O. After mixing evenly, apply a film. After the solvent is evaporated to dryness at 60°C, continue to dry at 80°C for 24 hours to obtain a solid film. The conductivity at room temperature is 7.6×10 -6 S cm -1 , the electrochemical window is 4.6V (for Li / Li + ), the lithium ion migration number is 0.90.

Embodiment 3

[0025] (1) Take 0.91g lithium aminotetrazolium salt, disperse it in 50mL DMSO, add an equimolar amount of IPDI diisocyanate (2.22g) dropwise at room temperature, stir until the emulsion becomes clear and set aside;

[0026] (2) Take 10.0 g of polyethylene glycol (PEG1000) in a single-necked bottle, add dropwise an equimolar amount of triethoxysilyl propyl isocyanate (2.5 g) under stirring at 80 ° C, and stir for 6 hours to obtain a uniform and transparent The solution is ready for use;

[0027] (3) Add the solution obtained in step (1) dropwise to the solution obtained in step (2) while stirring, and after reacting for 12 hours, add 0.1wt.% of H 2 O. After mixing evenly, apply a film. After the solvent is evaporated to dryness at 60°C, continue to dry at 80°C for 24 hours to obtain a solid film. The room temperature conductivity of the solid film is 6.1×10 -7 S cm -1 , the electrochemical window is 4.6V (for Li / Li + ), the lithium ion migration number is 0.91.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com