Ethylene and ethane adsorbing separation method based on ultramicroporous metal organic framework material

A metal-organic framework, adsorption separation technology, applied in separation methods, adsorption purification/separation, organic chemistry, etc., can solve the problems of high adsorption capacity and high adsorption selectivity, pollution, high energy consumption for regeneration, and achieve enhanced Molecular recognition ability, high adsorption capacity, effect of high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

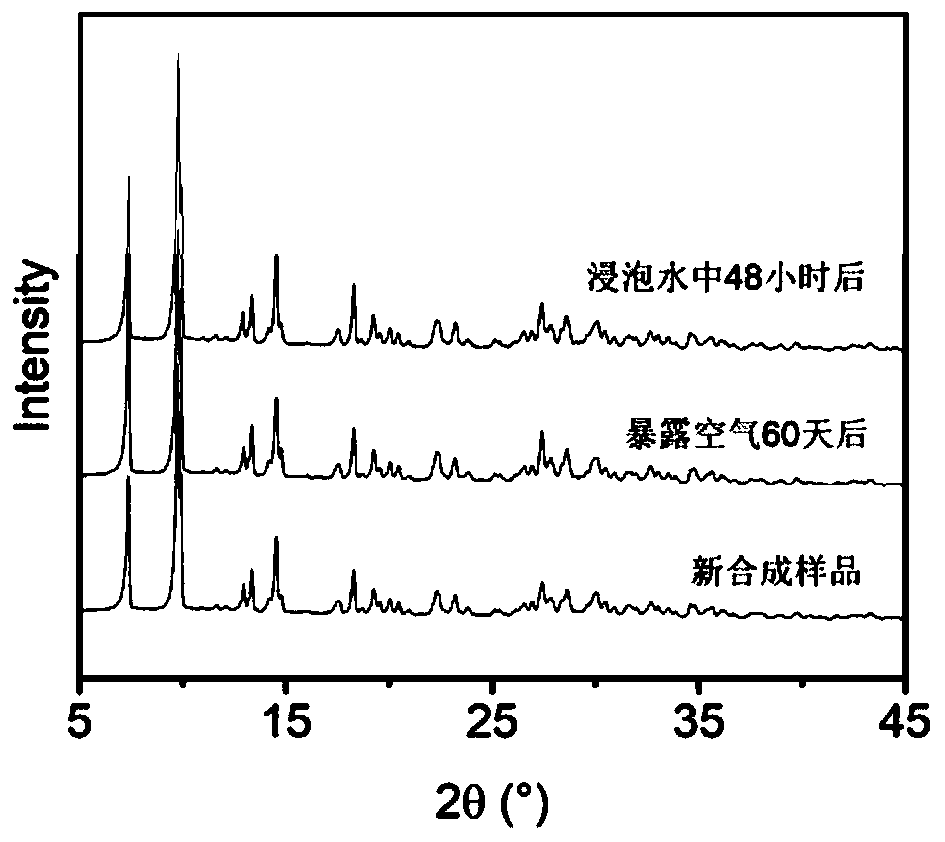

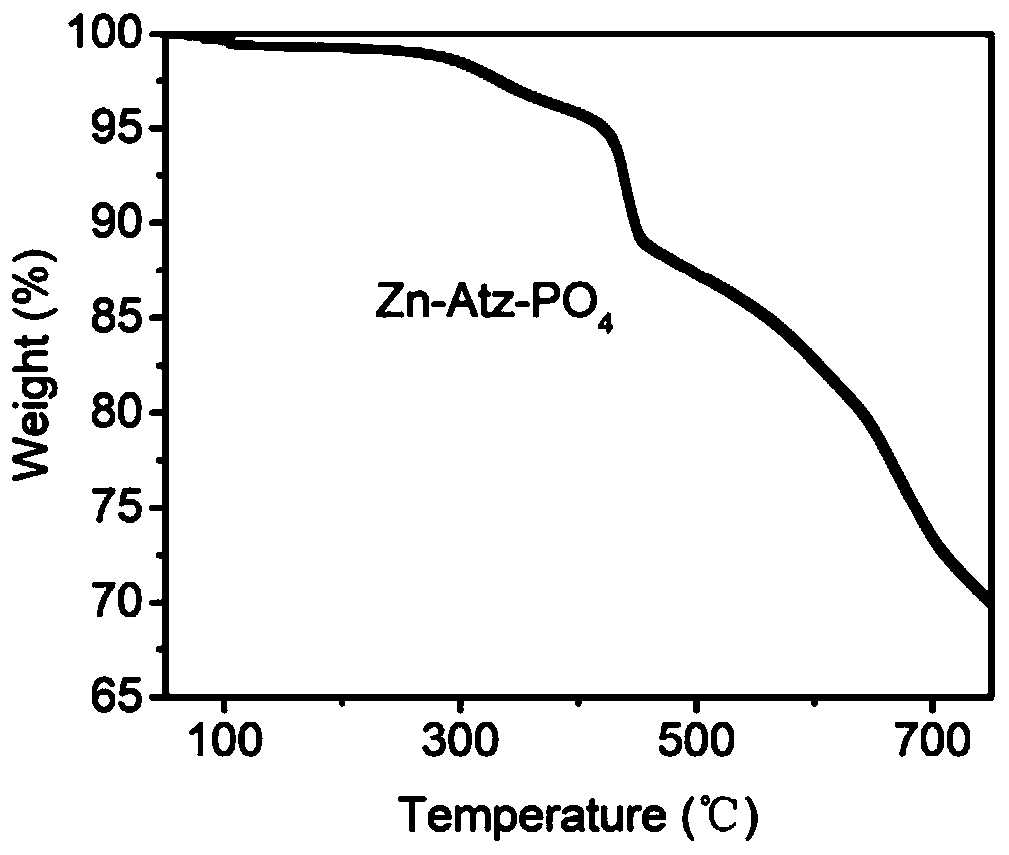

[0044] Using the method reported in the literature (Angewandte Chemie, 2012,124(8):1862-1865.), with phosphoric acid, Zn(OH) 2 · 2ZnCO 3 Synthesis of ultramicroporous metal-organic framework Zn-Atz-PO with 3-amino-1,2,4-triazole as raw material 4 . Utilize X-ray powder diffraction to analyze material, result ( figure 1 ) is consistent with the literature report, the size of the narrowest part of the material pore diameter is Zn-Atz-PO 4 The thermogravimetric curve of the material is as figure 2 As shown, the data show that it has high thermal stability, and its decomposition temperature is close to 420 °C.

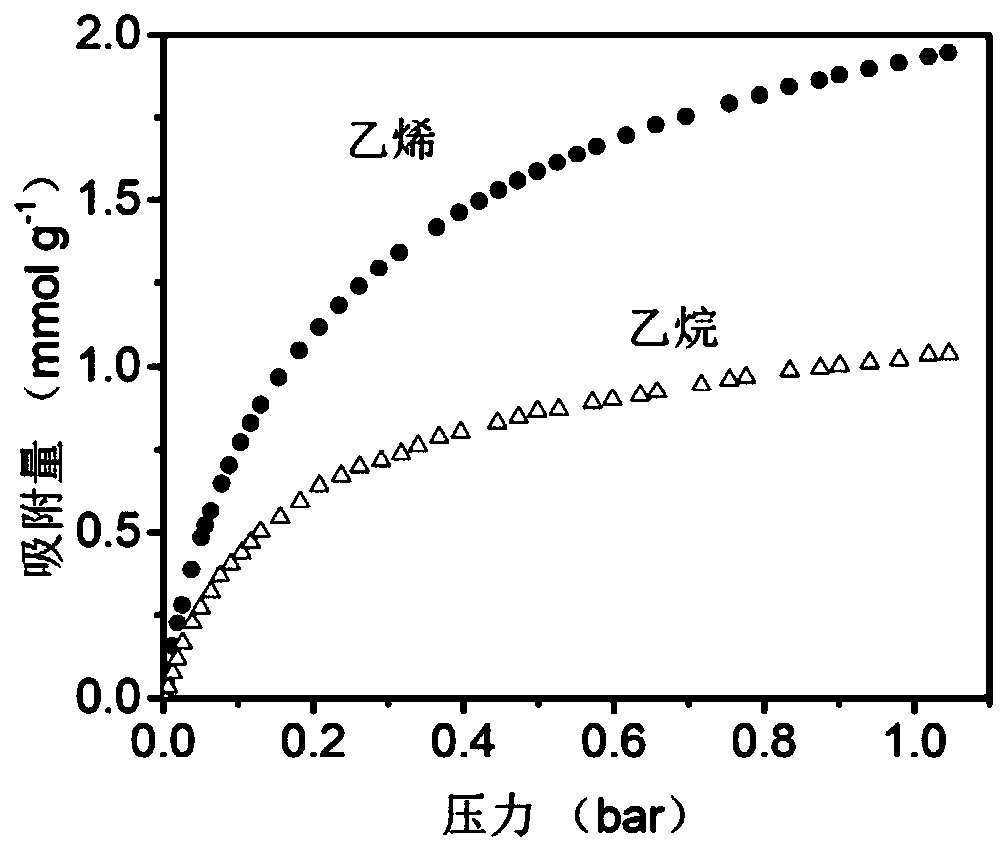

[0045] Measurement of Zn-Atz-PO 4 The adsorption isotherms and dynamic adsorption curves of materials for ethylene and ethane at 273K and 298K, the results are as follows Figure 3-6 shown. The results show that the synthesized Zn-Atz-PO 4 The equilibrium adsorption capacity of the material for ethylene and the diffusion rate of ethylene in its pores are signif...

Embodiment 2

[0048] CoCO 3 、Na 3 VO 4 and 3-chloro-1,2,4-triazole were added into a water / methanol mixed solvent with a volume ratio of 1:1 at a mass ratio of 1:1:4 and stirred evenly, and hydrochloric acid was added to adjust the pH of the reaction solution to 8.5, It was then placed in an oven at 120° C. for 48 hours to react. After the reaction, the obtained solid product was collected by suction filtration, washed several times with methanol, and then activated for 12 hours at 100°C in a vacuum environment to obtain the metal organic framework material Co-Cltz-VO 4 .

[0049] The resulting Co-Cltz-VO 4 The product was loaded into a 5cm fixed-bed adsorption column, and ethylene / ethane mixed gas (volume ratio 90:10) was passed into the bed at 298K and 8bar at a flow rate of 2.0mL / min for fixed-bed breakthrough experiments. Due to the weak interaction between the ethane component and the ultramicroporous material and the slow diffusion rate in its pores, it preferentially penetrates ...

Embodiment 3

[0051] With the Zn-Atz-PO of embodiment 1 gained 4 The material was loaded into a 5cm fixed-bed adsorption column, and ethylene / ethane mixed gas (volume ratio 50:50) was passed into the bed at 273K and 1bar at a flow rate of 0.5mL / min for fixed-bed breakthrough experiments. Such as Figure 8 As shown, after 27 minutes of adsorption, the ethane component preferentially penetrates the adsorption column, and high-purity ethane gas (99.999%) can be obtained from the outlet of the adsorption column. The ethylene component is enriched in the adsorption column and only penetrates the bed after about 70 minutes. After the adsorption column reaches equilibrium, stop the air intake, use the ethylene product gas obtained in Example 2 to sweep the bed for 10 minutes (0.5mL / min), and then vacuumize (<0.05bar) and heat (65°C) to The adsorption column is desorbed to obtain ethylene gas with a purity of 99%, and the regeneration of the adsorption column is completed at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com