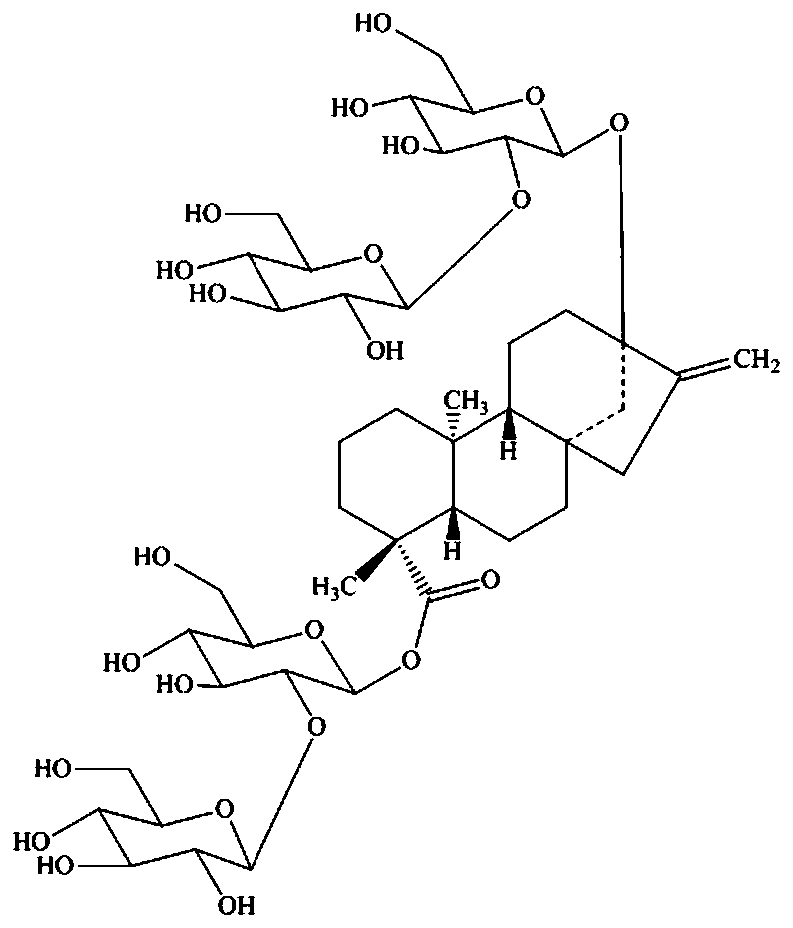

Method for preparing Rebaudioside E through enzyme method

A technology of enzymatic preparation and glycosyltransferase, which is applied in the field of enzymatic preparation of rebaudioside E, can solve the problems of low economic efficiency of rebaudioside E, simplify material preparation steps, improve preparation efficiency, and reduce work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the construction of recombinant escherichia coli genetically engineered bacteria

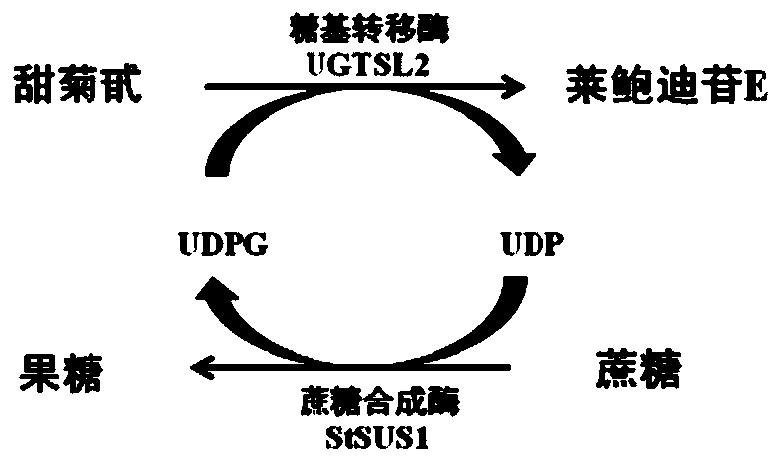

[0031] 1), acquisition of recombinant plasmids co-expressing UGTSL2 and StSUS1

[0032] The full sequence of UGTSL2 and StSUS1 genes was synthesized by Nanjing GenScript Company and constructed on the plasmid pRSFDuet-1 (Novagen Company), wherein the UGTSL2 gene fragment was inserted between the Nde I and Xho I restriction sites of the plasmid vector, and StSUS1 The gene fragment was inserted between the Nco I and EcoR I restriction sites of the plasmid vector, and finally a recombinant plasmid, pRSFDuet-UGTSL2-StSUS1, which can co-express glycosyltransferase UGTSL2 and sucrose synthase StSUS1 was provided.

[0033] 2), the acquisition of recombinant Escherichia coli genetically engineered bacteria

[0034] Add 40uL ddH 2 O into the recombinant plasmid pRSFDuet-UGTSL2-StSUS1 dry powder, fully dissolved, take 5ul of heat shock and transform into Escherichia coli BL21 (DE3) ...

Embodiment 2

[0035] Embodiment 2: the co-expression of genetically engineered bacteria double enzyme

[0036] Inoculate the recombinant genetically engineered bacteria containing plasmid pRSFDuet-UGTSL2-StSUS1 into LB medium containing 50mg / L kanamycin resistance (0.5g / L yeast powder, 1g / L sodium chloride, 1g / L tryptone) , shake overnight at 37°C and 200rpm, and then insert the culture bacteria into 100mL TB medium (2.5g / L yeast powder, 1g / L sodium chloride, 1.5g / L tryptone, 0.2g / L glucose, 0.05g / L lactose) in a 500mL shake flask, cultured at 200rpm at 37°C for 2h, then transferred to 25°C for 24h, and centrifuged to collect the bacteria. The cells were disrupted by ultrasonication, and the supernatant obtained by centrifugation was the crude cell extract, which was stored at 4°C until use.

Embodiment 3

[0037] The method of embodiment 3 enzymatic preparation rebaudioside E

[0038] 1), catalytic reaction system

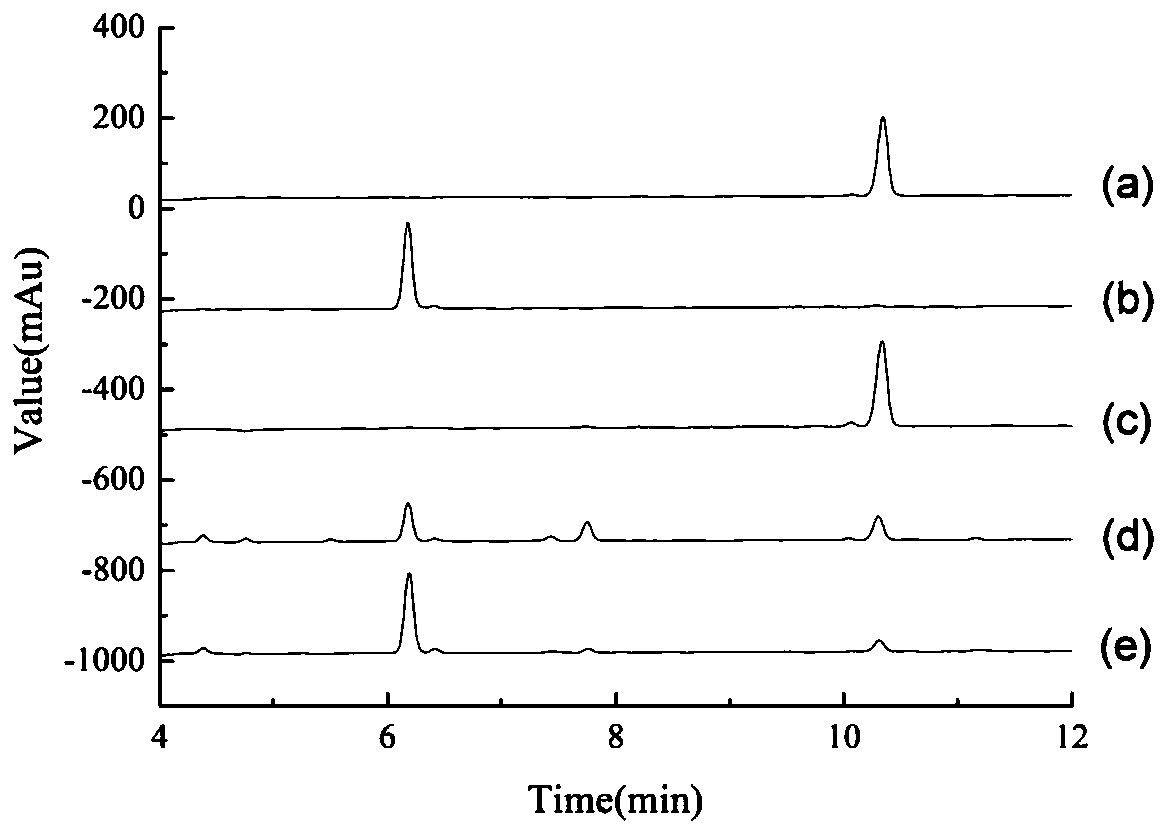

[0039] Add 20g / L stevioside, 60g / L sucrose, 3mM Mg 2+ And an appropriate amount of crude cell extract (~6 mg / mL total protein) co-expressing UGTSL2 and StSUS1 in 50 mM potassium phosphate buffer (pH 7.2), and the total volume was quantified to 20 mL. React at 30°C and 200rpm for 24h, sample 500uL at regular intervals, heat in a water bath at 95°C for 15min, centrifuge at room temperature at 12000rpm for 1min, separate the supernatant into a new 1.5mLEP tube, store at 4°C, and wait for HPCL detection. From the results (Table 1), it is feasible to catalyze the synthesis of rebaudioside E from stevioside by the coupling of glycosyltransferase UGTSL2 to sucrose synthase, and at the time of reaction for 24 hours, the conversion rate of stevioside has reached 94.12%. The yield of diglycoside E was 66.32%.

[0040] 2), PHLC detection method

[0041] Chromatographic colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com