A kind of cobalt tetroxide catalyst for catalytic combustion of methane and its preparation and application

A cobalt tetroxide catalyst, methane catalytic combustion technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as high temperature and long reaction time, and achieve The effect of simple raw materials, easy access to raw materials, and simple operation of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 4

[0024] Example 1 Cobalt Tetroxide Nanosheets Co 3 o 4 - Preparation of NSs

[0025] Mix 4.2g cobalt acetate tetrahydrate and 40mL ethylene glycol solution uniformly to prepare solution A; add 8g sodium hydroxide to 40mL ethylene glycol solution and mix uniformly to prepare solution B. Wherein, the ethylene glycol solution is obtained by uniformly mixing ethylene glycol and deionized water at a volume ratio of 1:1. Solution A and solution B were mixed after magnetic stirring for 3 hours to form a sol; the obtained sol was transferred to a hydrothermal autoclave (100 mL), and gradually heated to 150 ° C in a blast drying oven and kept for 20 hours; the obtained product was then deionized with After washing with water, dry at 70°C for 12h; place the dried sample in a muffle furnace and calcinate at 300°C for 4h, and the obtained material is named Co 3 o 4 -NSs.

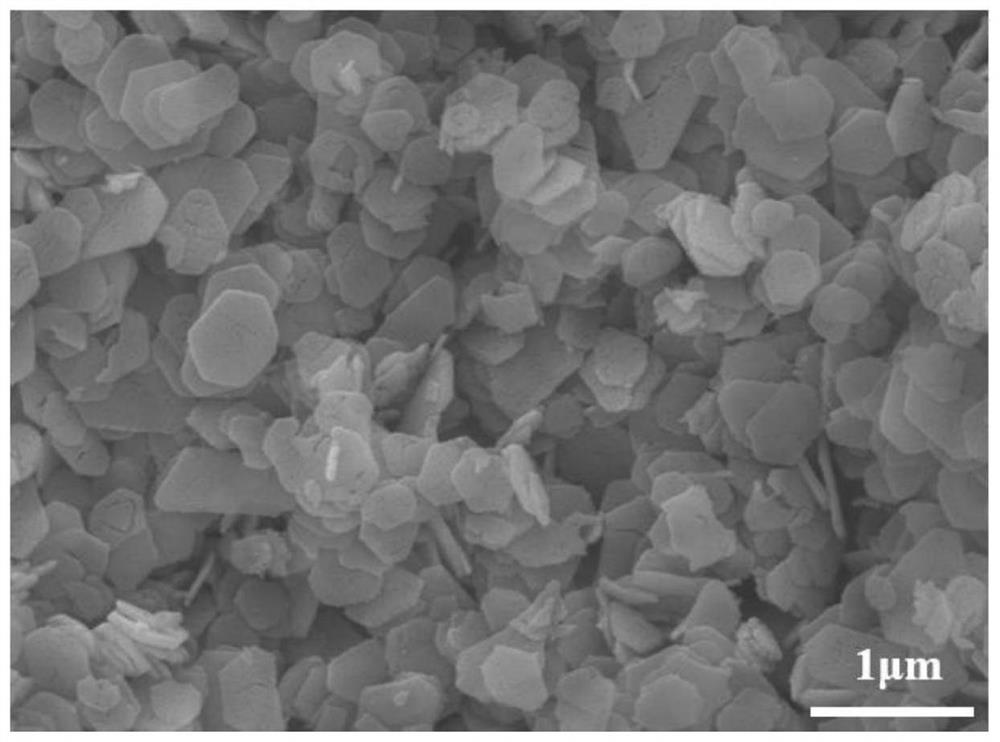

[0026] figure 1 For the Co prepared in Example 1 3 o 4 -SEM images of NSs, figure 1 Shown in Co 3 o 4 -Nano...

Embodiment 2

[0027] Embodiment 2 is used for the tricobalt tetroxide catalyst Co of methane catalytic combustion 3 o 4 -Preparation of Na

[0028] In a glove box filled with Ar, the Co prepared in Example 1 3 o 4 -NSs and elemental sodium were manually ground in an agate mortar for 1 h at a grinding rate of 2 rpm; the mass of elemental sodium was Co 3 o 4 -0.5% of the mass of NSs, put the ground sample in a beaker, add 100mL of deionized water and a rotor, and stir for 1h. Use a vacuum pump filter device, wash with deionized water to PH = 7, and dry the obtained sample at 70 °C for 12 hours in a blast drying oven. The obtained material is named Co 3 o 4 -Na.

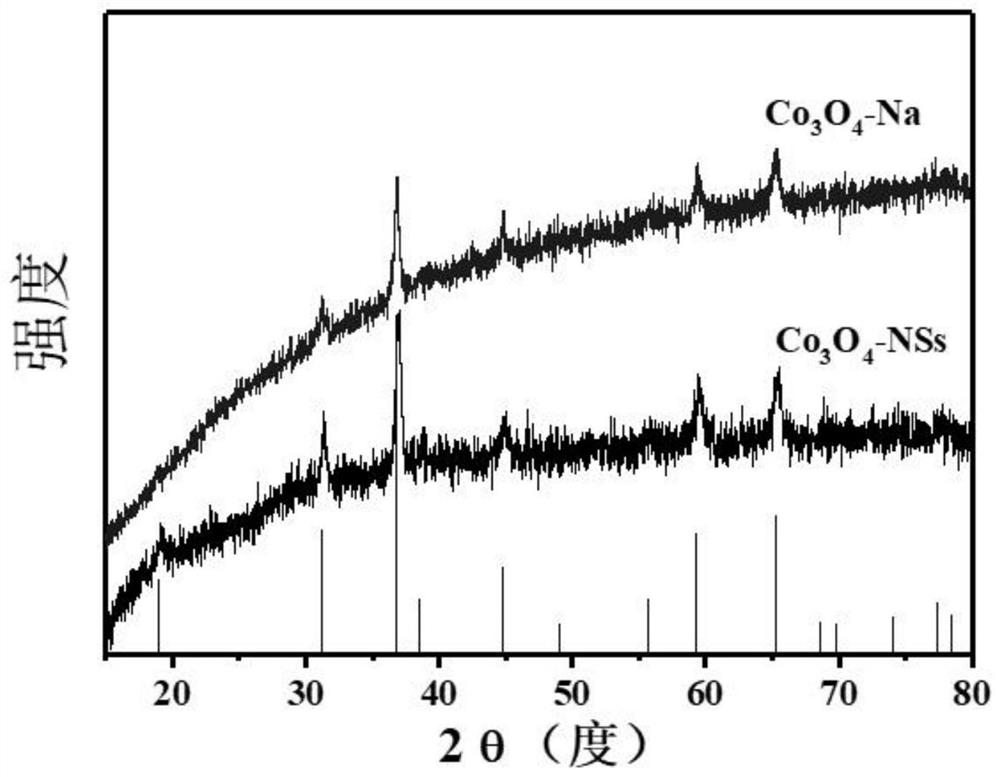

[0029] figure 2 For the Co prepared in Example 1 3 o 4 -NSs and the Co prepared in Example 2 3 o 4 -XRD spectrum of Na, from figure 2 It can be seen that the morphology of cobalt tetraoxide nanosheets before and after treatment has not changed in crystal phase.

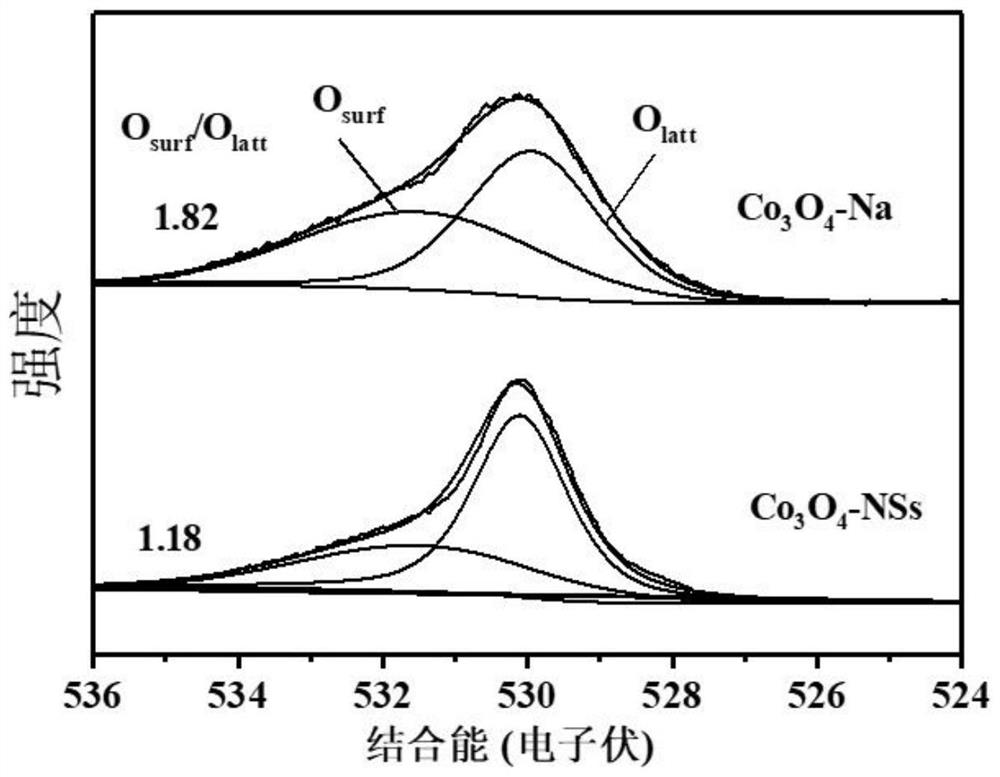

[0030] image 3 For the Co prepared in Example 1 3 o 4...

Embodiment 3

[0034] Embodiment 3 is used for the tricobalt tetroxide catalyst Co of methane catalytic combustion 3 o 4 Catalytic Combustion Reaction of -Na to Methane

[0035] Adopt each 0.1g of the catalyst in embodiment 1-2 respectively, pack in the fixed-bed reactor, mass air velocity 21000mL / g / h, carry out the measurement of methane conversion rate, the change of the methane concentration in the tail gas is measured by gas chromatography, reflects the gas The composition is: 2% methane, 20% oxygen, and nitrogen as the balance gas. The conversion effect of the catalyst on methane was measured at 100-850°C, and the test results are shown in Figure 5 , at a space velocity of 21000mL / g / h, the performance of the material after sodium treatment was significantly improved compared with that before treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com