Construction method of mixed type drainage lithium ion battery system based on lithium cobalt oxide and activated carbon

A lithium-ion battery and activated carbon technology, which is applied in the direction of non-aqueous electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of high cost of lithium-ion batteries, restrictions on wide application, and battery failure, so as to weaken the proton intercalation effect and improve Circulation and the effect of improving lithium storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] S1. Configure electrolyte:

[0047] S11. Configuration of LiOH solution with pH=13: Weigh 0.1mol LiOH and dissolve it in a 1000ml volumetric flask filled with deionized water. After the crystals are completely dissolved, use deionized water to calibrate the concave surface of the solution to the 1000ml scale. The configuration of LiOH solution with pH=13 is completed;

[0048] S12, 0.5M Li at pH=11 2 SO 4 Solution configuration: weigh 15.995g Li 2 SO 4 ·H 2 After O, measure 2.5ml from the solution configured in step S1 and transfer it to a 250ml volumetric flask, add deionized water to dilute and introduce the weighed Li 2 SO 4 ·H 2 O crystals, after the crystals are completely dissolved, use deionized water to calibrate the horizontal concave surface of the solution to a distance of 0.5cm from the 250ml scale, then use a pH meter to detect pH=10.97, and use a dropper to draw a small amount of pH=13 prepared in step S1 The solution was pH compensated to pH=11, 0...

Embodiment 2

[0066]Embodiment two differs from embodiment one in that:

[0067] Step S22, in the mixed slurry, add the positive electrode material to the beaker one by one, which is 0.75g spherical LiCoO 2 (prepared by hydrothermal template method combined with high temperature sintering) or negative electrode material 0.75g AC, 0.15g acetylene black;

[0068] Step S24, in PTFE fiberization, place the beaker containing the slurry obtained in step S3 on a magnetic stirrer, and stir at a speed of 30 r / s until the slurry in the container is creamy and fine, then stop stirring, and the PTFE fiber completed;

[0069] Step S25, electrode preparation: uncover the sealed plastic wrap on the beaker, put the beaker containing the slurry in an oven at 80°C to dry the slurry, and then obtain the electrode mixture and collect it in a sample box for later use;

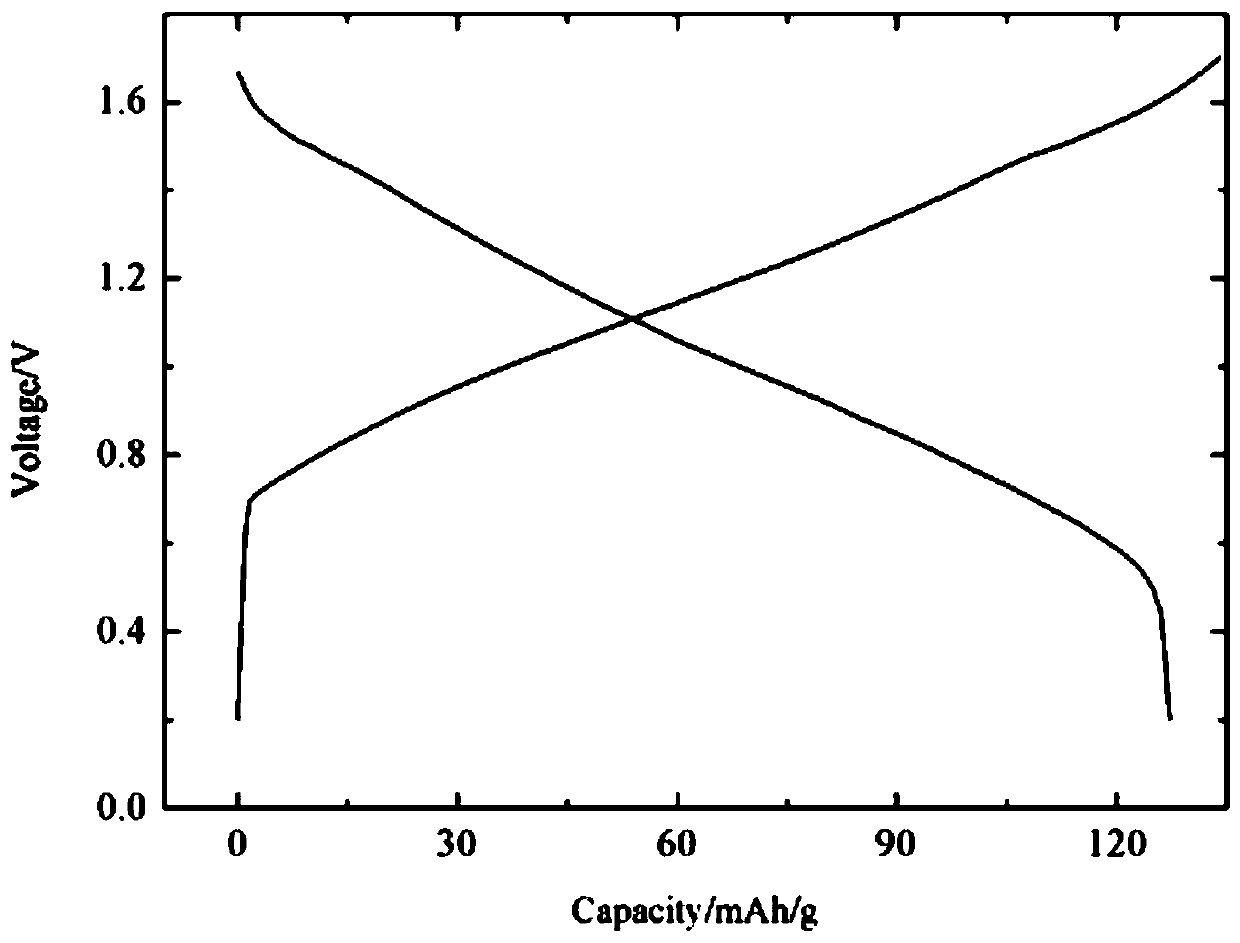

[0070] In step S3, specific capacity C1=169mAh / g;

[0071] In step S5, C1:C2=m2:m1=2.85;

[0072] Step S6, construction of the battery syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com