Inorganic-organic sun-screening agent composite microsphere and preparation method thereof

An organic sunscreen and composite microsphere technology, applied in the field of daily chemical industry, can solve the problems of increasing skin allergies, aging and lesion risks, human safety risks, skin adverse reactions, etc., to reduce photodegradation and skin irritation , prevent penetration into the skin or hair follicles, superior human body safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The pH value of 0.9g nano-titanium dioxide (particle diameter is 10-25nm, anatase type) is adjusted to 3, ultrasonic 5min obtains water dispersant, this water dispersant is standby as aqueous phase;

[0036] Weigh 4.3g of hydrogen-containing silicone oil (PMHS, hydrogen content 3%), 7.5g of avobenzone and 10.7g of vinyl-terminated silicone oil (Vi-PDMS) and mix them uniformly as the oil phase;

[0037] Mix the above water phase and oil phase, and add 2×10 -5 (Based on the mass fraction of Pt in the mixture of PMHS and Vi-PDMS) chloroplatinic acid catalyst, homogenized at 20000r / min for 2min to obtain a white emulsion, reacted in the dark at 25°C for 24h, and prepared the product at 60°C Dry and grind to obtain inorganic-organic sunscreen composite microspheres.

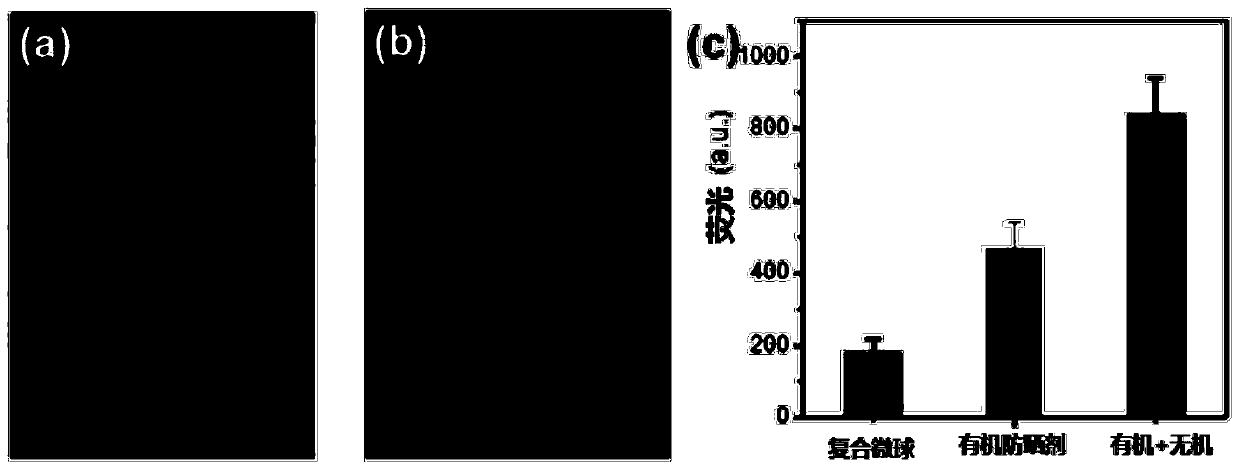

[0038] Such as figure 1 As shown in (a) and (b), it can be seen from the SEM image of the microsphere and the photomicrograph of the emulsion that the particle size of the microsphere is 3-20 μm; the ultravio...

Embodiment 2

[0040] Utilize ultrasound to disperse 0.15g zinc oxide (particle size is 30nm) to 30g10 -4 mol / L cetyltrimethylammonium bromide (CTAB) aqueous solution, add 0.15g nano silicon dioxide (about 16nm), and adjust the pH value to 4, ultrasonic 5min, get water dispersant and disperse the water The agent is used as the aqueous phase for subsequent use;

[0041] Weigh 9g methyl methacrylate (MMA), and add 0.45g terexylylene biscamphorsulfonic acid (Mai Su Ning filter ring) and mix uniformly as the oil phase;

[0042] Mix the water phase and the oil phase, then add 0.3g of potassium persulfate (KPS) as a catalyst, homogenize at 20,000r / min for 2min to obtain a white emulsion, fill it with nitrogen and stir for 12h at 20°C in the dark, and the product is simply After filtering, vacuum-dry in the dark at 40°C for 36 hours to obtain PMMA microspheres with a mysuning filter ring inside and titanium dioxide on the surface.

[0043]The particle size of the microspheres is 0.1-10 μm; the ul...

Embodiment 3

[0045] Utilize ultrasound to disperse 0.6g of nano-titanium dioxide (particle size is 100nm) into 30g of 10-4mol / L CTAB solution, and ultrasonic 10min to obtain a water dispersant, the water dispersant is used as the water phase for standby;

[0046] Weigh 20g styrene, 3g octocrylene (OCR), 3g ethylhexyl methoxycinnamate (EHMC) and mix well as the oil phase;

[0047] Mix the water phase and the oil phase, and add 0.2g of azobisisobutyronitrile as a catalyst, homogenize at 20,000r / min for 5min to obtain a white emulsion, react in the dark at 60°C for 1h, and dissolve the product at 40°C Vacuum drying for 36 hours and grinding to obtain PS microspheres with ORC and EHMC inside and ZnO on the surface.

[0048] The particle size of the microspheres is 100-200 μm; the ultraviolet light test shows that the inorganic-organic sunscreen composite microspheres have a full-band sunscreen effect, which is twice as high as that of zinc oxide alone and ORC and EHMC composite sunscreen; Oxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com