Copper oxide@nickel molybdate/ foamed copper composite electrode material and preparation method thereof

A composite electrode and foamed copper technology, which is applied in the field of preparation of inorganic non-metallic materials, can solve the problem that the capacitance value of electrode materials is difficult to meet the supercapacitor and other problems, and achieve the effects of excellent electrochemical performance, increasing contact area and reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) 20mmol sodium hydroxide and 2mmol ammonium persulfate are fully dissolved in 40 milliliters of deionized water at room temperature, and the cleaned and dried foamed copper is immersed in the above mixed solution to obtain a copper hydroxide / foamed copper composite material;

[0034] (2) Fully dissolve 1.5mmol nickel nitrate and 1.5mmol sodium molybdate in 40 ml of deionized water, immerse the copper hydroxide nanowire array / copper foam obtained in step (1) in the above solution, and conduct a hydrothermal reaction at 90°C After 1 hour, after natural cooling, the obtained sample was washed and dried;

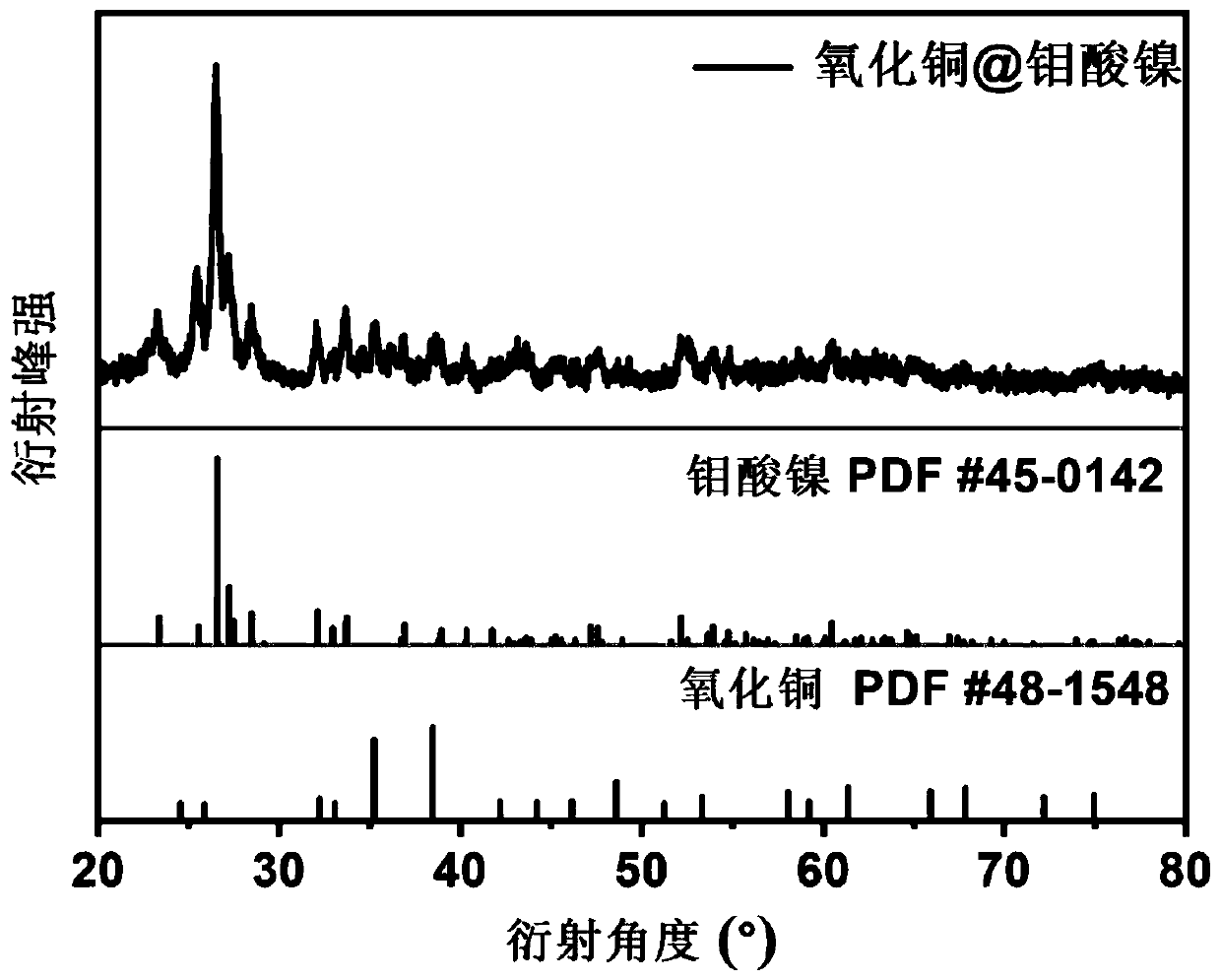

[0035] (3) The product obtained in step (2) was calcined in a nitrogen atmosphere at 350° C. for 2 hours to form a copper oxide@nickel molybdate / copper foam composite electrode material.

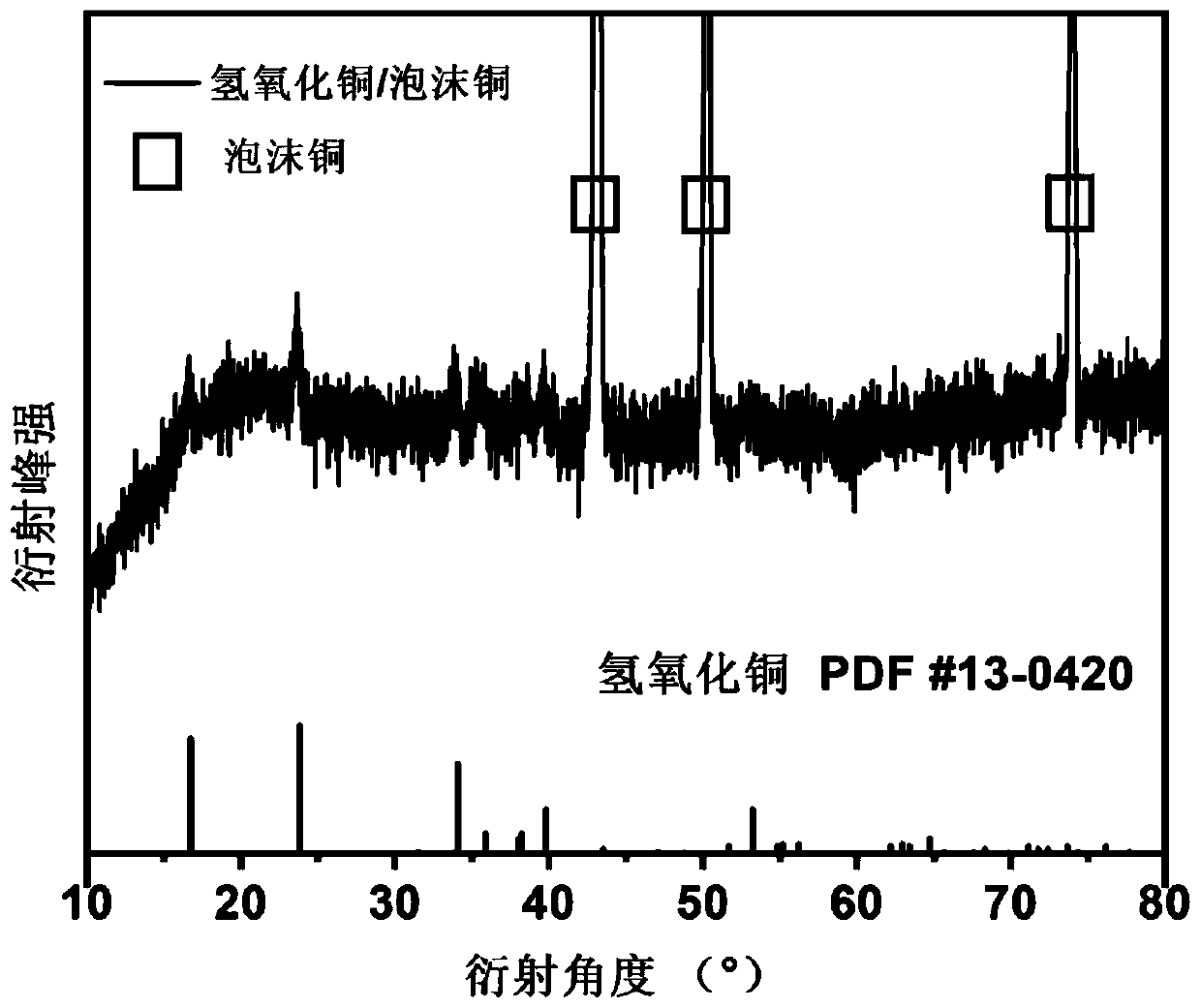

[0036] From X-ray Diffraction Spectrum figure 1 , and scanning electron microscope photographs figure 2 It can be seen that step (1) successfully synthesized copper hydroxide nano...

Embodiment 2

[0038] (1) 40 mmol sodium hydroxide and 2 mmol ammonium persulfate are fully dissolved in 40 milliliters of deionized water at room temperature, and the cleaned and dried foamed copper is immersed in the above mixed solution to obtain a copper hydroxide / foamed copper composite material;

[0039] (2) Fully dissolve 1.5mmol nickel nitrate and 1.5mmol sodium molybdate in 40 ml of deionized water, immerse the copper hydroxide nanowire array / copper foam obtained in step (1) in the above solution, and conduct a hydrothermal reaction at 90°C After 2 hours, after natural cooling, the obtained sample was washed and dried;

[0040] (3) The product obtained in step (2) was calcined in a nitrogen atmosphere at 350° C. for 2 hours to form a copper oxide@nickel molybdate / copper foam composite electrode material.

[0041] The copper oxide@nickel molybdate nanoarray obtained under the conditions of Example 2 is basically the same as that in Example 1.

Embodiment 3

[0043] (1) 20mmol sodium hydroxide and 2mmol ammonium persulfate are fully dissolved in 40 milliliters of deionized water at room temperature, and the cleaned and dried foamed copper is immersed in the above mixed solution to obtain a copper hydroxide / foamed copper composite material;

[0044] (2) Fully dissolve 1.5mmol nickel nitrate and 1.5mmol sodium molybdate in 40 ml of deionized water, immerse the copper hydroxide nanowire array / copper foam obtained in step (1) in the above solution, and conduct a hydrothermal reaction at 90°C After 6 hours, after natural cooling, the gained sample was washed and dried;

[0045] (3) The product obtained in step (2) was calcined in a nitrogen atmosphere at 450° C. for 2 hours to form a copper oxide@nickel molybdate / copper foam composite electrode material.

[0046] The copper oxide@nickel molybdate nanoarray obtained under the conditions of Example 3 is basically the same as that obtained in Example 1, but the diameter of the nanowires ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com