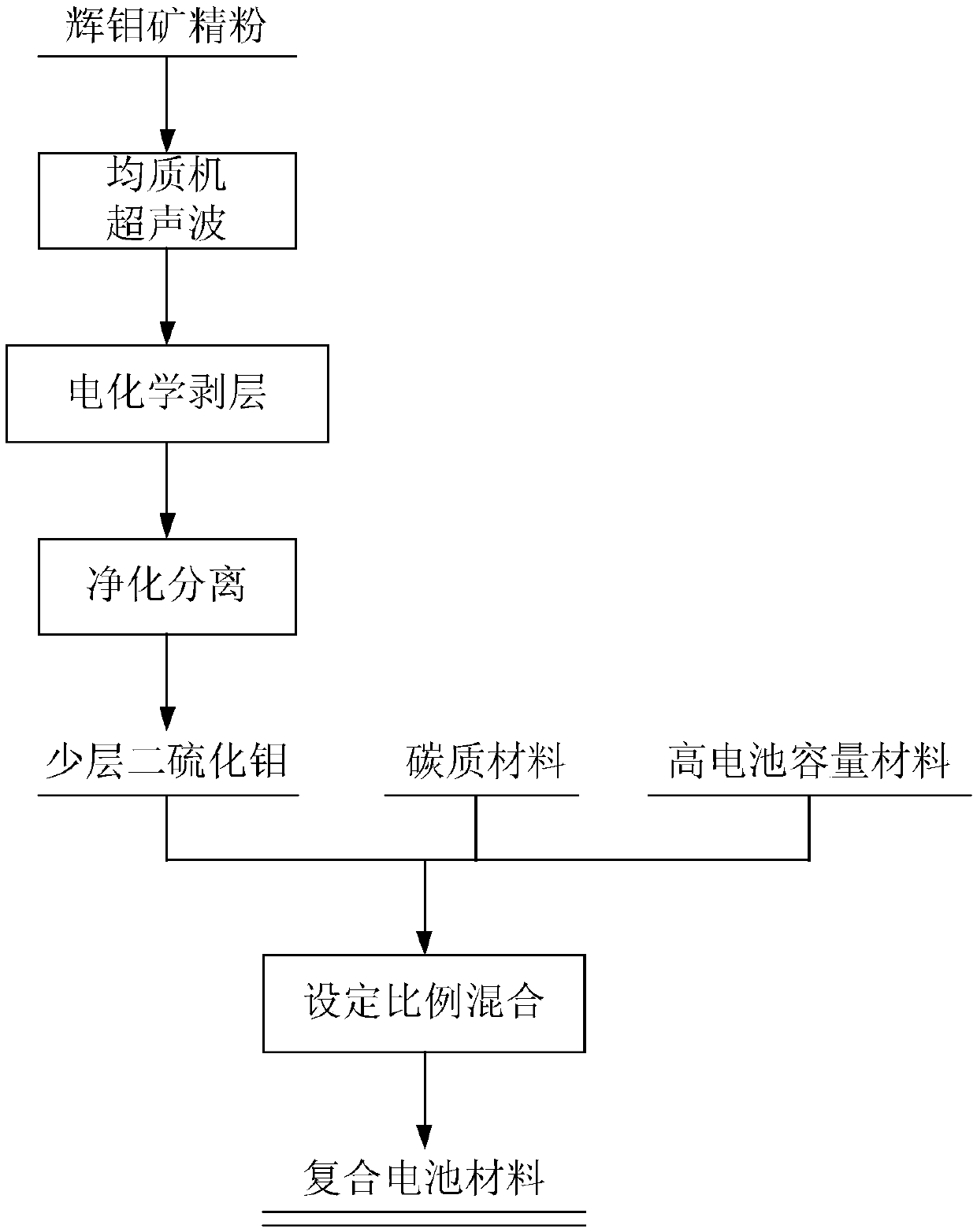

Novel battery material and preparation method and application thereof

A battery material and new technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of decreased battery cycle stability, limited to artificial synthesis, active material shedding, etc., to achieve high yield, high specific capacity, The effect of long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] First, at room temperature, use molybdenite fine powder with a Mo content of 57% obtained from ore dressing and enrichment as raw material, and grind it into molybdenite fine powder with an average particle size of 10 μm; Delamination treatment, shear rate at 50000s -1 , the concentration of molybdenite micropowder in the suspension is controlled at 0.5%, the temperature of the suspension is controlled at 20°C, and the treatment time is 0.5h to prepare the molybdenite suspension; Centrifuge for 10 minutes, after the centrifuged solid is dried, mix the obtained solid material with sodium carboxymethyl cellulose and conductive carbon black in a mass ratio of 70:15:15, add an appropriate amount of ultrapure water to make a slurry and apply it to nickel After the water evaporates, place it in a vacuum drying oven, and dry it at 100°C for 12 hours to prepare an electrode sheet. Then the prepared electrode containing molybdenum disulfide is used as the negative electrode, an...

example 2

[0036] First, at room temperature, use molybdenite fine powder with a Mo content of 59% obtained from ore dressing enrichment and hydrometallurgical impurity removal as raw material, and grind it into molybdenite fine powder with an average particle size of 30 μm; then use high-shear homogeneous The machine carries out the peeling treatment of molybdenite powder, and the shear rate is 20000s -1 , the concentration of molybdenite micropowder in the suspension is controlled at 5%, the temperature of the suspension is controlled at 60°C, and the treatment time is 6h to prepare a molybdenite suspension; the molybdenite suspension is centrifuged at a speed of 150,000rpm for 10min , after the centrifuged solid is dried, the obtained solid material is mixed evenly with sodium carboxymethyl cellulose and conductive carbon black in a mass ratio of 70:15:15, and an appropriate amount of ultrapure water is added to make a slurry and coated on a nickel mesh. After the water is volatilized...

example 3

[0038] First, at room temperature, molybdenite fine powder with a Mo content of 58% obtained by hydrometallurgical removal of impurities was used as raw material to grind molybdenite fine powder with an average particle size of 40 μm; then a high-shear homogenizer and ultrasonic Peeling treatment of molybdenite fine powder, the shear rate of the homogenizer is 150000s -1 , the ultrasonic frequency is controlled at 100kHz, the ultrasonic power is 900W, the concentration of molybdenite micropowder in the suspension is controlled at 8%, the temperature of the suspension is controlled at 90°C, and the treatment time is 4h, the molybdenite suspension is prepared; the molybdenite The ore suspension was centrifuged at 15,000 rpm for 10 minutes, and the centrifuged solids were dried. Mix the obtained solid material with sodium carboxymethyl cellulose and conductive carbon black evenly in a mass ratio of 70:15:15, add an appropriate amount of ultrapure water to make a slurry and apply ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com