Graphene quantum dot modified manganese oxide/titanium oxide nanotube array material and preparation method and application thereof

A technology of titanium oxide nanotubes and graphene quantum dots, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of low photocatalytic efficiency and visible light utilization. Low, photogenerated electron-hole recombination rate is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing a graphene quantum dot modified manganese oxide / titanium oxide nanotube array material, comprising the following steps:

[0027] Using titanium sheet as the positive electrode and graphite plate as the negative electrode, anodic oxidation and annealing are performed sequentially to obtain titanium oxide nanotube arrays in the anatase phase;

[0028] Preoxidizing the reduced graphene oxide in concentrated sulfuric acid and concentrated nitric acid solutions to obtain preoxidized graphene;

[0029] After mixing the pre-oxidized graphene and water, the ammonia water adjusts the pH value to be weakly alkaline, and performs a hydrothermal reaction to obtain a graphene quantum dot solution;

[0030] Taking the titanium oxide nanotube array in the anatase phase as the positive electrode, and the platinum sheet as the negative electrode, immersing in the graphene quantum dot solution, and performing an electrolytic reaction to obtai...

Embodiment 1

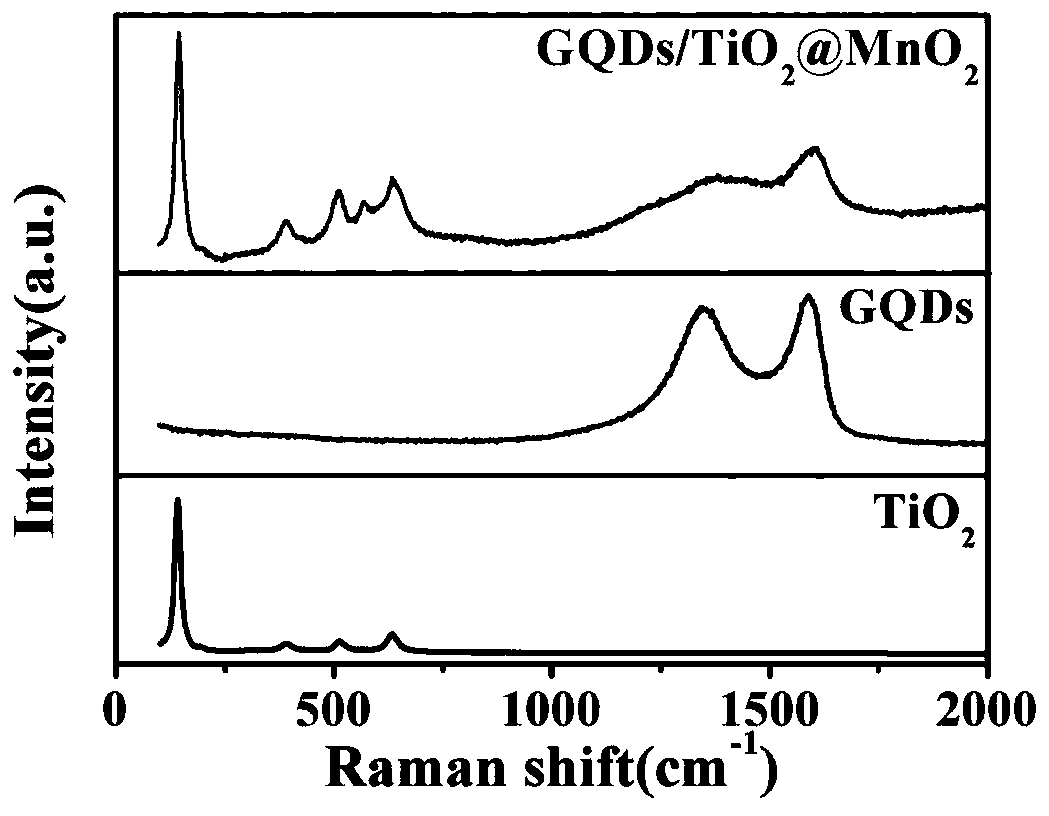

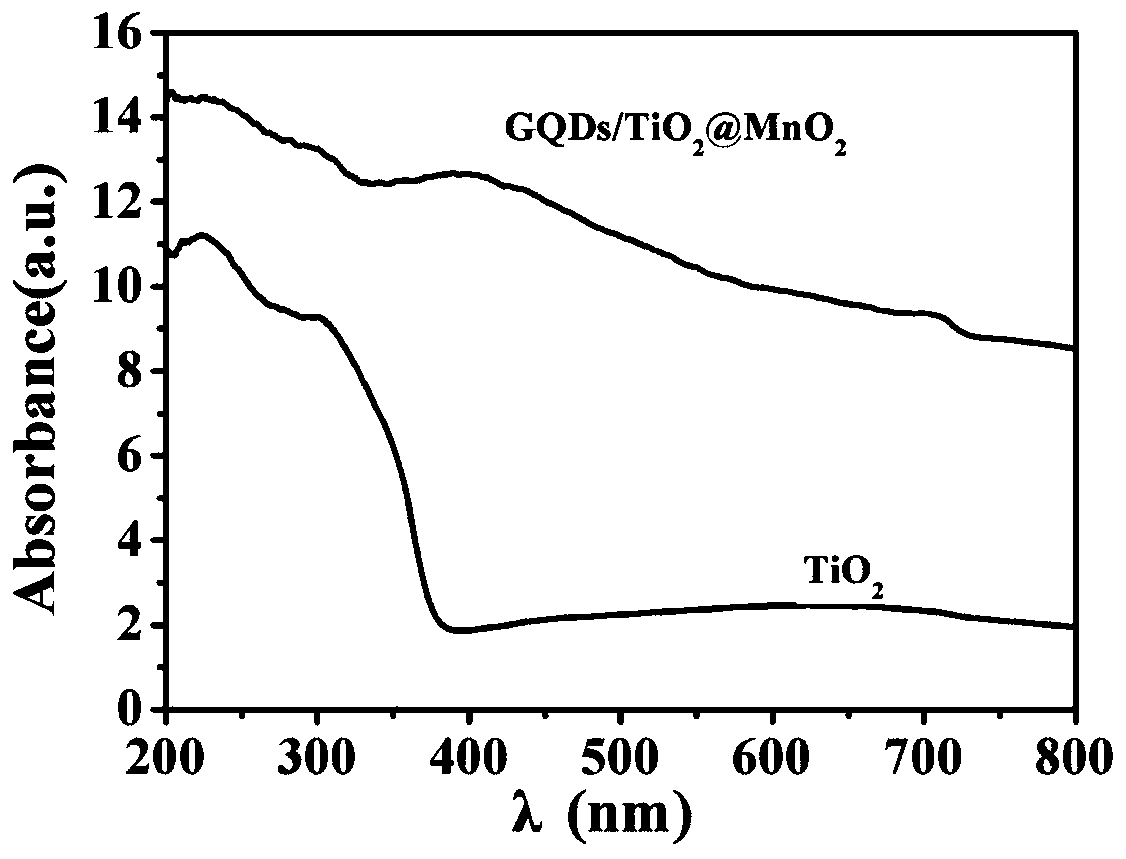

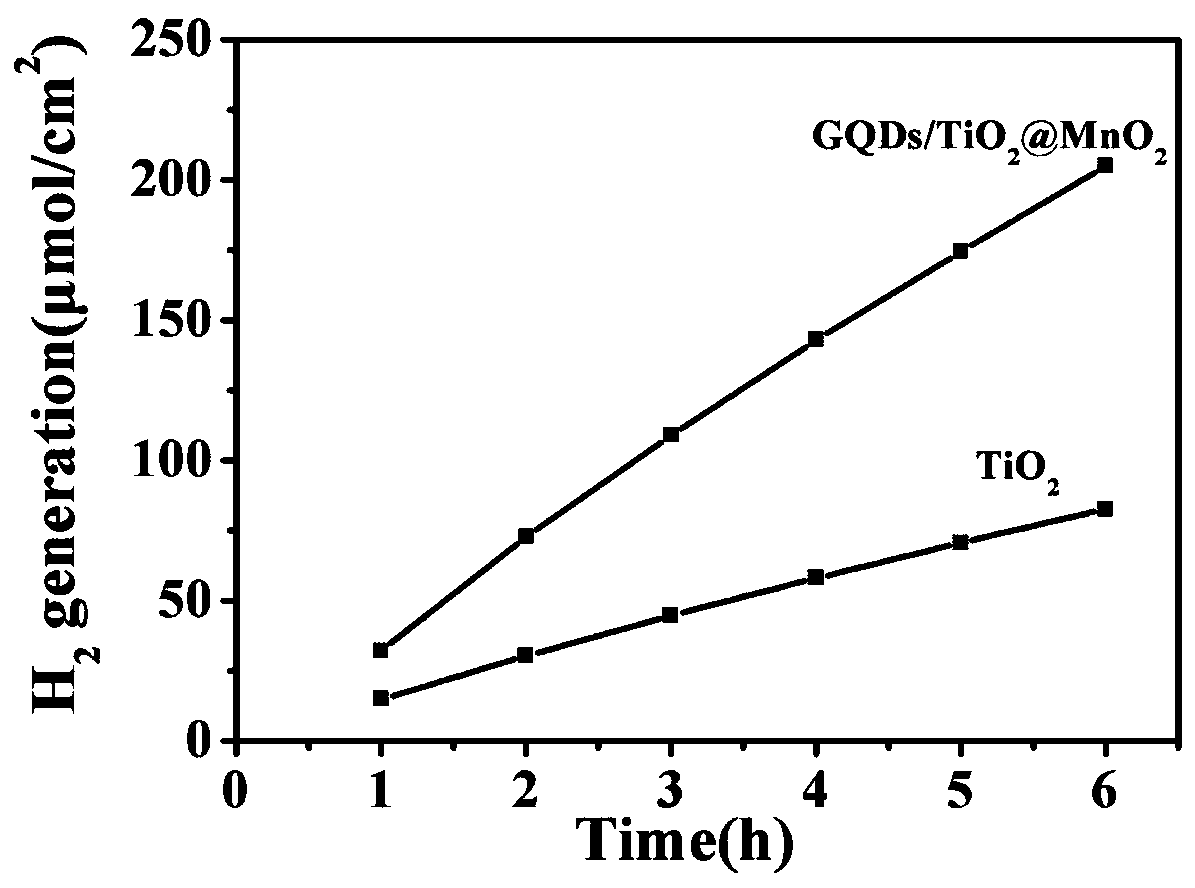

[0052] First, cut the titanium sheet into a 2*4cm sheet, place it in acetone, ethanol, and deionized water for 15 minutes, and then place it in ethylene glycol electrolysis containing 0.25mol ammonium fluoride and 3vt% deionized water. In the solution, the titanium sheet is used as the positive electrode, and the graphite sheet is used as the negative electrode. Anodize at 60V for 4h, take out the titanium sheet and put it in deionized water for ultrasonication until the surface film falls off, rinse it with deionized water, Drying, continue anodizing at 60V for 6h, ultrasonication in ethylene glycol for 15min, annealing at 450°C for 2h at a heating rate of 2°C / min, to obtain titanium dioxide nanotube arrays in anatase phase. Graphene oxide was prepared according to the improved Hummers method, which was placed in a tube furnace with a flow rate of 40cc of argon gas, and the temperature was raised to 500°C at a rate of 2°C / min, and reduced graphene oxide was obtained after hold...

Embodiment 2

[0054] The preparation method of the titanium dioxide nanotube array of anatase phase is the same as that of Example 1. Graphene oxide was prepared according to the improved Hummers method, and the preparation method of graphene quantum dots (light yellow clear liquid) was the same as in Example 1.

[0055] The obtained titanium oxide nanotubes were placed in the obtained liquid, the titanium oxide was used as the positive electrode, and the platinum sheet was used as the negative electrode, and a voltage of 5 V was added to react for 8 hours to obtain a quantum dot-modified titanium oxide nanotube array. Dissolve 0.5g of potassium permanganate in 50mL of deionized water, immerse the quantum dot-modified titanium oxide nanotube array in the solution, drop in 200μL of concentrated sulfuric acid, put it in a water bath and keep it at 95°C for 30min to obtain quantum dot modification Manganese oxide / titanium oxide nanoarray materials (GQDs / TiO 2 @MnO 2 ). The obtained samples ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com