Catalyst to prepare glycolic acid via formaldehyde carbonylation and preparation method and application thereof

A technology of glycolic acid and catalyst, which is applied in the field of catalyst and its preparation for the carbonylation of formaldehyde to prepare glycolic acid, which can solve the problems of high reaction pressure, high reaction temperature, and high equipment requirements, and achieve low reaction pressure, high purity, and excellent product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

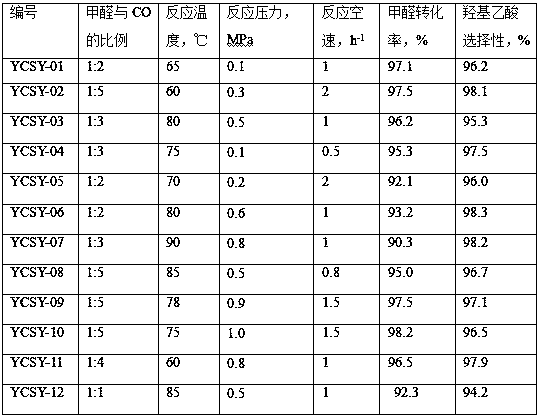

Examples

Embodiment 1

[0020] A catalyst for the preparation of glycolic acid by carbonylation of formaldehyde, comprising a main catalyst, a co-catalyst and a carrier, according to 100 parts by weight, the main catalyst includes 20 parts of titanium oxide, 5 parts of zinc oxide, and 8 parts of zirconium oxide. The promoter includes 1 part of lanthanum oxide, 2 parts of neodymium oxide, and the rest is 64 parts of carrier ZSM-5 molecular sieve; the catalyst number is marked as YCSY-01;

[0021] The preparation method of the catalyst: After immersing the carrier with 1mol / L sodium hydroxide solution for 24h to activate, the carrier is washed with deionized water to neutrality, and configured according to the component ratio of the main catalyst into a metal with a total mass fraction of 5%. Sulphate or chloride salt solution to obtain the main catalyst solution; according to the component ratio of the co-catalyst, it is configured into a metal sulfate or chloride solution with a total mass fraction of...

Embodiment 2

[0023] A catalyst for the preparation of glycolic acid by carbonylation of formaldehyde, comprising a main catalyst, a co-catalyst and a carrier, according to 100 parts by weight, the main catalyst includes 15 parts of titanium oxide, 8 parts of zinc oxide, and 2 parts of zirconium oxide, the The promoter includes 2 parts of lanthanum oxide, 1 part of neodymium oxide, and the rest is 72 parts of carrier ZSM-5 molecular sieve; the catalyst number is marked as YCSY-02;

[0024] The preparation method of described catalyst is with embodiment 1.

Embodiment 3

[0026] A catalyst for the carbonylation of formaldehyde to prepare glycolic acid, comprising a main catalyst, a co-catalyst and a carrier, according to 100 parts by weight, the main catalyst includes 12 parts of titanium oxide, 2 parts of zinc oxide, and 8 parts of zirconium oxide. The promoter includes 5 parts of lanthanum oxide, 2 parts of neodymium oxide, and the rest is 71 parts of carrier MCM-41 molecular sieve; the catalyst number is marked as YCSY-03;

[0027] The preparation method of described catalyst is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com