A kind of nano-iron compound/mesophase carbon microsphere composite material and preparation method thereof

A technology of mesocarbon microspheres and composite materials, which is applied in the direction of electrochemical generators, structural parts, electrical components, etc., can solve the problems of easy agglomeration of nucleating agent particles and difficulty in uniform dispersion, and achieve simple and easy-to-operate synthesis steps, The process is simple and feasible, and the effect of reversible capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of nano iron compound / mesophase carbon microsphere composite material, the steps are as follows:

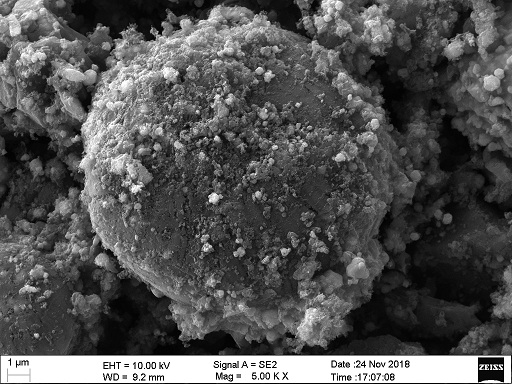

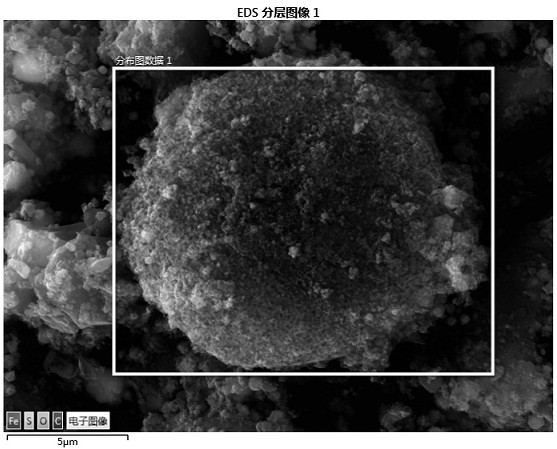

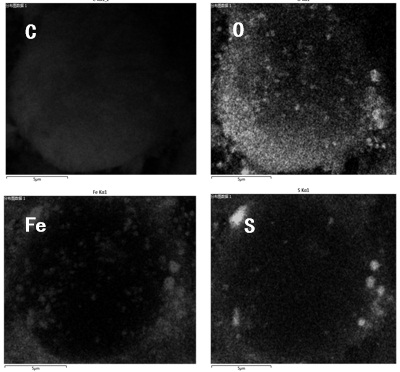

[0027] Select high-temperature coal tar to distill to obtain coal tar pitch, and the coal tar pitch is pretreated to remove quinoline insoluble matter. Take 500 g of dequinoline-insoluble coal tar pitch, iron oleate and sublimed sulfur, and mix them uniformly into the reactor at a mass ratio of 100: 3: 0.2. At a reaction temperature of 380 ° C, a reaction pressure of 2 MPa, a stirring speed of 100 rpm, and a heating Under the condition of a rate of 5 °C / min, the reaction was carried out in a nitrogen atmosphere for 4 h, and the nitrogen flow rate was 1 L / min. The product was separated from washing oil and then vacuum-dried to obtain the precursor of nano-iron compound / mesophase carbon microspheres. The mass ratio of washing oil to product was 3:1, and the dissolution temperature was 180°C. The composite material precursor was carbonized under argon protect...

Embodiment 2

[0033] The preparation of nano iron compound / mesophase carbon microsphere composite material, the steps are as follows:

[0034] Another kind of coal tar pitch is selected, and the coal tar pitch is pretreated to remove quinoline insoluble matter. Take 500 g of dequinoline-insoluble coal tar pitch, ferrocene and sublimed sulfur, and mix them uniformly into the reactor at a mass ratio of 100: 1: 0.1. At a reaction temperature of 400 ° C, a reaction pressure of 1 MPa, a stirring speed of 150 rpm, and a heating Under the condition of a rate of 5 °C / min, the reaction was carried out in a nitrogen atmosphere for 2 h, and the nitrogen flow rate was 0.5 L / min. The product was separated from toluene and then vacuum-dried to obtain the precursor of nano-iron compound / mesophase carbon microspheres. The mass ratio of toluene to product was 1:1, and the dissolution temperature was 80°C. The composite material precursor was further carbonized at 900 °C for 2 h under argon protection, with...

Embodiment 3

[0037] The preparation of nano iron compound / mesophase carbon microsphere composite material, the steps are as follows:

[0038] Select 500g of petroleum asphalt, ferric oleate and mercaptan according to the mass ratio of 100: 7: 0.6 and evenly blend them into the reactor. Under the condition of , react in nitrogen atmosphere for 6 h, nitrogen flow rate 1.5L / min. The product was separated from the washing oil and then vacuum-dried to obtain the precursor of nano-iron compound / mesophase carbon microspheres. The mass ratio of washing oil to product was 4:1, and the dissolution temperature was 150°C. The composite material precursor was further carbonized under nitrogen protection at 1000 °C for 1 h, with a heating rate of 5 °C / min and a nitrogen flow rate of 100 mL / min, to obtain nano-iron compound / mesophase carbon microsphere composites.

[0039] Compared with the reaction without the addition of oil-soluble iron, the yield of carbon microspheres increased by 8 % and the D50 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com