Slurry bed hydrogenation catalyst, and preparation method and application thereof

A hydrogenation catalyst and slurry bed technology are applied in the field of slurry bed hydrogenation catalyst and its preparation, and can solve the problems of low hydrogenation efficiency, poor selectivity, and reduction of precious metal content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Preparation of Silica Hydrogenation Catalyst

[0045] Weigh 2 g of spherical silicon oxide powder with a particle size of 200-400 mesh, place the above powder in a tubular calcining furnace, and then perform nitridation treatment on the silicon oxide carrier through the following procedure.

[0046] a) First, the gas in the roasting tube is replaced by nitrogen gas for 30 minutes, and the oxygen content in the tail gas of the detection device is lower than 0.5%.

[0047] b) feeding into the mixed gas of nitrogen and ammonia with a volume flow of 30ml / min, wherein the volume concentration of ammonia is 70%;

[0048] c) adopt the heating rate to be 5 ℃ / min and be heated to 750 ℃, and obtain the nitrided silicon oxide carrier after maintaining this temperature for 24hr;

[0049] D) configure the palladium nitrate aqueous solution of 2mg / ml, then add above-mentioned palladium nitrate solution 5ml in the silicon oxide carrier of nitridation, then carry out 120 ℃ of dryin...

Embodiment 2

[0057] Preparation of Silica Hydrogenation Catalyst

[0058] The preparation of the hydrogenation catalyst supported by silicon oxide is similar to the above-mentioned method for supporting the active components of silicon nitride oxide. Briefly, prepare 20ml of 10mg / ml palladium nitrate aqueous solution, then weigh 2g of spherical silicon oxide powder with a particle size of 200-400 mesh, add 5ml of palladium nitrate solution of the above-mentioned concentration to the above-mentioned silicon oxide powder, and then carry out 120 ° C. Dry, 350 ℃ of calcinations 3hr obtain the palladium catalyst of oxidation state; Put the palladium catalyst of above-mentioned oxidation state into the tubular furnace, pass into the hydrogen that volume flow is 30ml / min, at temperature, be obtained after reducing 5hr at 80 ℃ Hydrogenation palladium catalyst.

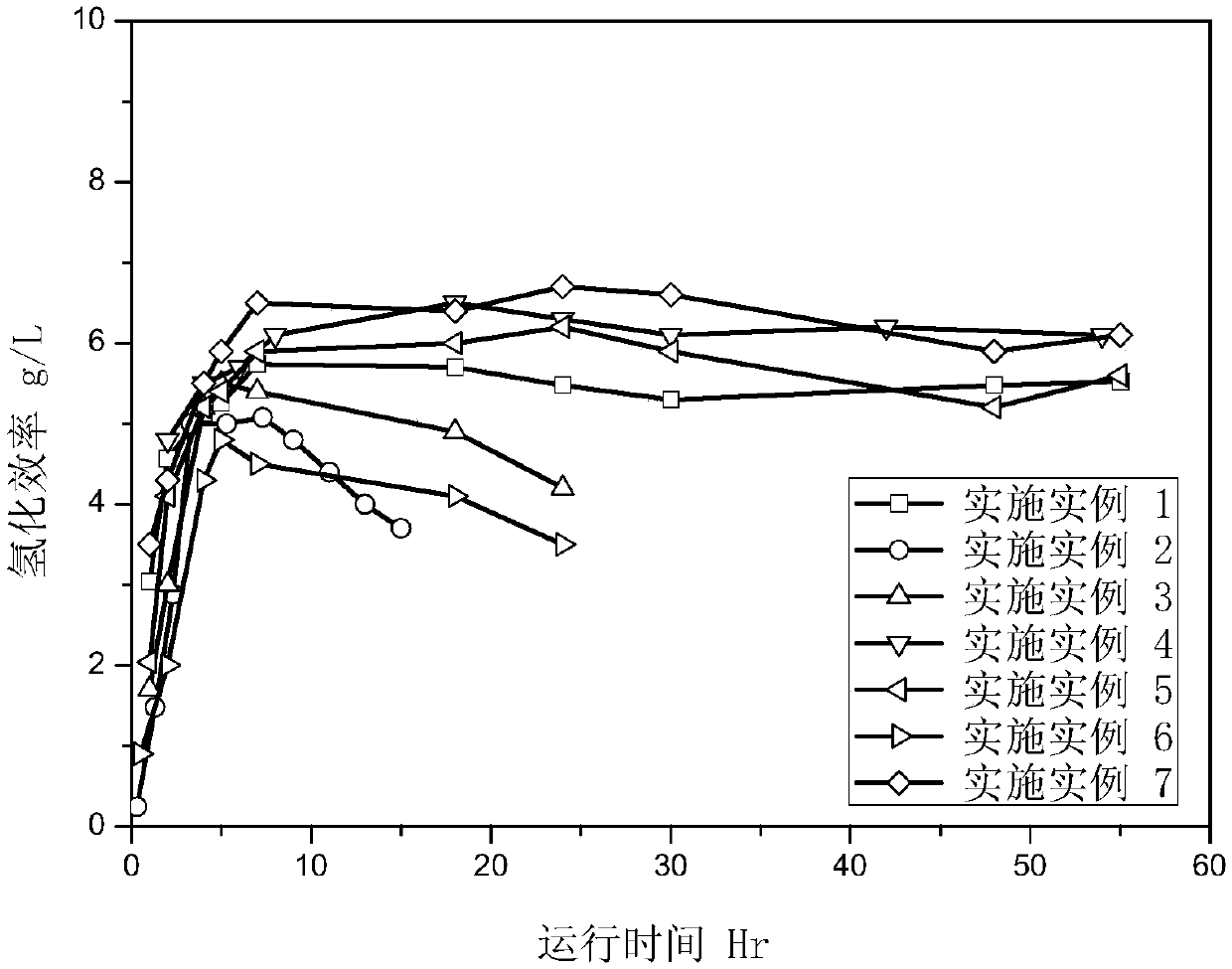

[0059] The physical parameters of amorphous silica are shown in Table 1. The comparative results of hydrogenation evaluation are as fol...

Embodiment 3

[0061] Preparation of Silica Hydrogenation Catalyst

[0062] The preparation steps are as described in Example 1; other conditions are the same, the concentration of ammonia gas in the mixed gas of nitrogen gas and ammonia gas is 10%, and the nitriding time is kept at 1 hr. The physical parameters of silicon oxide after nitridation are shown in Table 1.

[0063] The silicon oxide nitrogen content after nitridation measured by the alkali fusion method was 0.9%. The evaluation results of the hydrogenation catalyst are as follows: figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com