Highly-dispersed supported slurry bed hydrogenation bead catalyst and preparation method thereof

A granular catalyst and supported technology, which is applied in the field of high-dispersion loaded slurry bed hydrogenation granular catalyst and its preparation, can solve the problems of desorption of unfavorable reaction products, so as to facilitate hydrogen overflow, avoid shiny production, The effect of improving hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

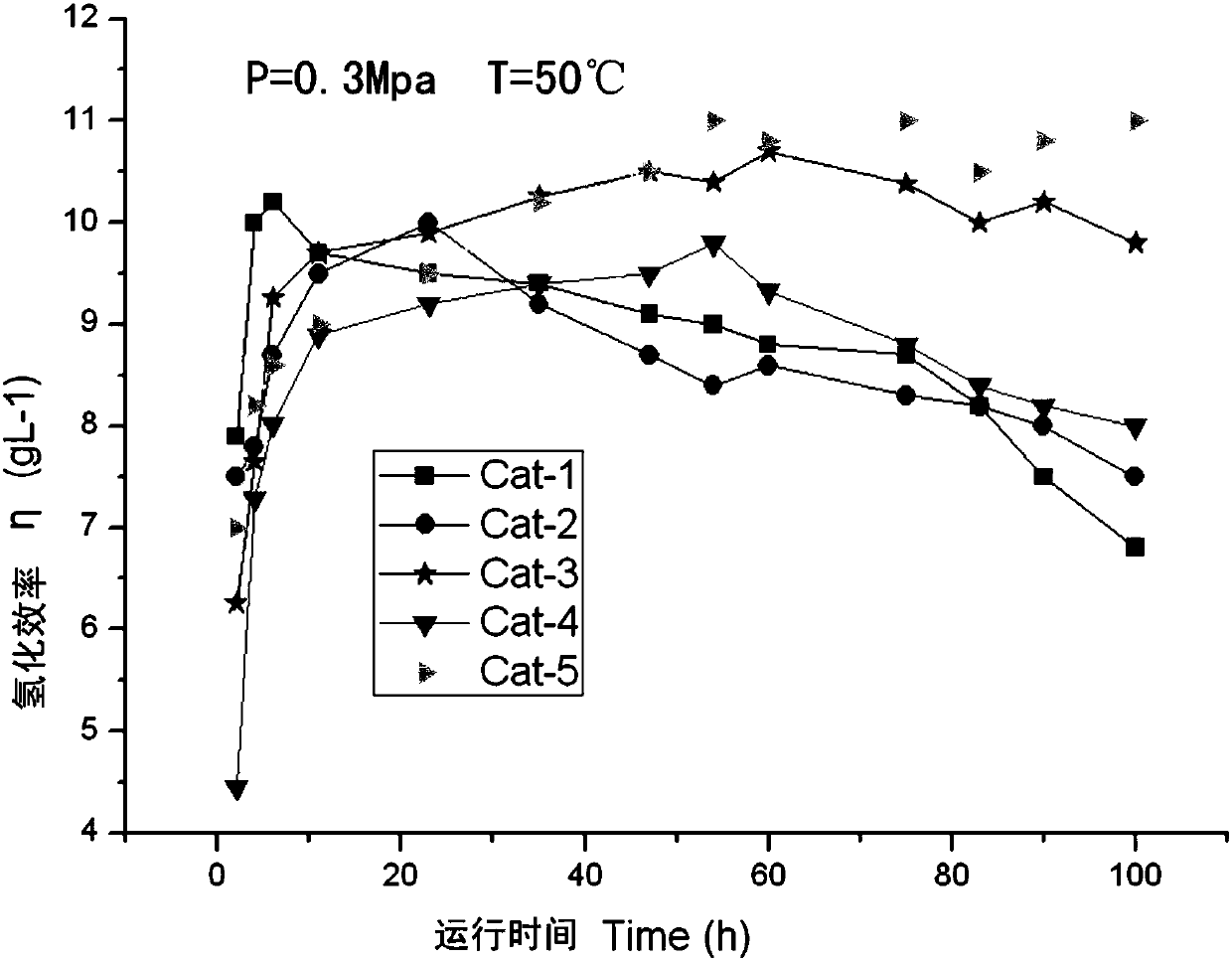

Examples

Embodiment 1

[0045] 1-1 Weigh 50 g of microspherical silica particles with an average particle size of 60 μm, add it to a hydrochloric acid solution with a concentration of 1 wt % at a temperature of 50 °C, fully immerse it for 10 hours, then take it out and dry it at a temperature of 120 °C to obtain a catalyst carrier A. use;

[0046] 1-2 Take 10g of X-type molecular sieve, 4g of zirconium nitrate, 30g of aluminum sol (40wt%), 5g of silica sol (30wt%), and 1g of ethanol and mix them in a 100ml ball mill. 2 hours to obtain mixed slurry B;

[0047] 1-3 Using the dipping method, the slurry B is evenly loaded on the carrier A, the dipping time is 30 minutes, and the carrier C of the hydrogenation catalyst is obtained after drying at 80 ° C and calcining at 500 ° C for 10 hours; 3.4% of silica particles;

[0048] 1-4 Take 30ml of H with a concentration of 20mg / ml 2 PdCl 4 The precious metal solution is impregnated on the catalyst carrier, and after being evenly impregnated, the solution i...

Embodiment 2

[0051] 2-1 Weigh 50 g of microspherical silica particles with an average particle size of 50 μm, add it to a NaOH solution with a concentration of 1 wt% at a temperature of 40 °C, soak it for 2 hours, and then take it out and dry it at a temperature of 120 °C to obtain a catalyst carrier A, which is ready for use ;

[0052] 2-2 Mix 5g of Y-type molecular sieve, 43g of silica sol (30wt%), and 2g of methanol in a 100ml ball mill, adjust the rotation speed of the ball mill to 500r / min, and mill it for 2 hours to obtain mixed slurry B;

[0053] 2-3 The slurry B was evenly loaded on the carrier A by the dipping method, and the dipping time was 30 min. After drying at 80°C and calcining at 500°C for 10 hours, the carrier C of the hydrogenation catalyst was obtained; the measured coating mass accounted for microns 1.8% of silica particles;

[0054] 2-4 Take 30ml of Pd(NO) with a concentration of 20mg / ml 3 ) 2 The precious metal solution is impregnated on the catalyst carrier, and ...

Embodiment 3

[0057] 3-1 The preparation of the catalyst carrier is the same as that of Example 2, and the catalyst carrier A is obtained for use;

[0058] 3-2 Mix 15g of ZSM-5 molecular sieve, 25g of aluminum sol (40wt%), 8g of silica sol (30wt%), and 2g of ethanol in a 100ml ball mill, adjust the speed of the ball mill to 500r / min, and mill the ball for 2 hours , to obtain mixed slurry B;

[0059]3-3 The slurry B was evenly loaded on the carrier A by the dipping method. The dipping time was 30 min. After drying at 80°C and calcining at 500°C for 10 hours, the carrier C of the hydrogenation catalyst was obtained; 5.6% of silica particles;

[0060] 3-4 Take 30ml of Pd(NO) with a concentration of 20mg / ml 3 ) 2 The precious metal solution is impregnated on the catalyst carrier, and after being evenly impregnated, the solution is placed in a microwave oven for rapid drying, and then placed in a muffle furnace for calcination at 500° C. for 8 hours to obtain a hydrogenation catalyst in an ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com