Micron/nano aluminum powder composite particle coated with fluorine-containing polymer and preparation method thereof

A nano-aluminum powder and composite particle technology, which is used in offensive equipment, non-explosive/non-thermal agent components, and compressed gas generation, etc. Conditional acquisition, good density, and performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

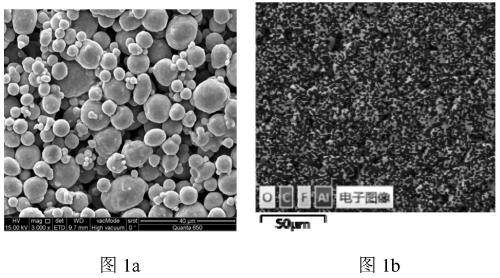

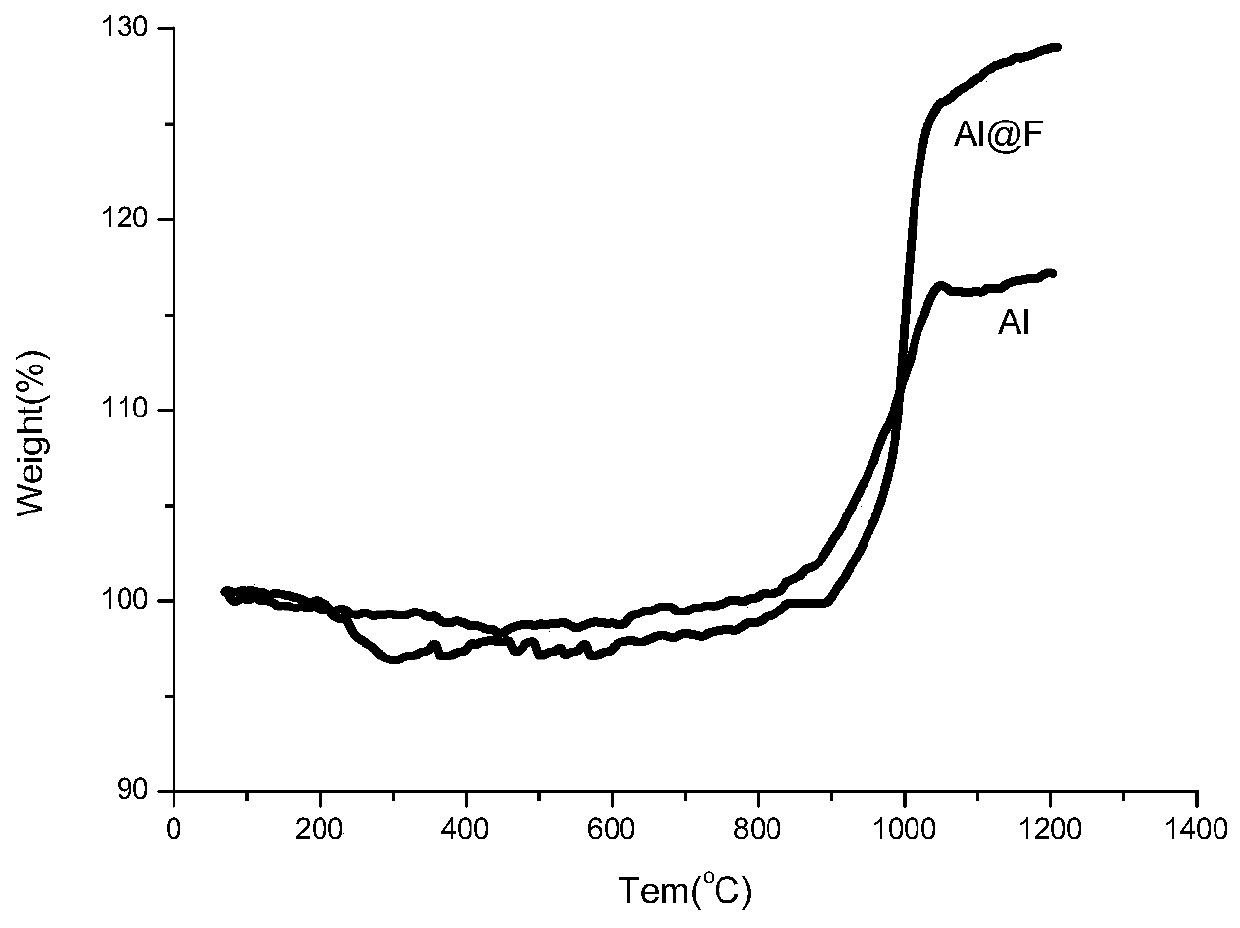

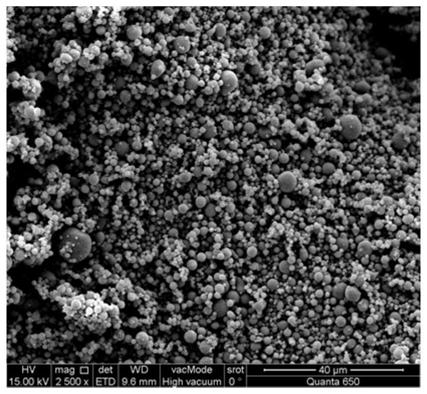

[0035] The fluorine-containing polymer-coated micro / nano-aluminum powder composite particle of the present invention is micron or nano-aluminum powder coated with polyfluorinated alkyl acrylate, and the coating thickness is 50 nm to 2 μm. The specific preparation method includes the following steps:

[0036] Step (1), according to the mass ratio, under the protection of nitrogen or inert gas, add micron or nanometer aluminum powder (10-100 parts), polyethylene Pyrrolidone (1-10 parts), low-carbon chain unsaturated fatty acid (0.05-1.5 parts), alcohol solvent (100-2000 parts), ultrasonic dispersion to uniformly disperse the aluminum powder in the alcohol solvent.

[0037] D of the above-mentioned nano-aluminum powder 50 Between 1 and 200nm, the D of micron aluminum powder 50 Between 1 and 50 μm.

[0038] The inert gas mentioned above is high-purity argon, high-purity helium and the like.

[0039]The above-mentioned low carbon chain unsaturated fatty acids used as functional ...

Embodiment 1

[0051] Under the protection of inert gas argon, add 10g FLQT-3 aluminum powder, 1.0g polyvinylpyrrolidone, 0.5g acrylic acid, 200ml n-butanol solvent into a 2L three-neck flask equipped with a reflux condenser and a constant pressure dropping funnel, and ultrasonically disperse Aluminum powder is uniformly dispersed in n-butanol solvent. Heat the above reaction solution to 65°C under vigorous stirring; slowly add the toluene solution (0.5g AIBN+10g toluene solvent) into the above reaction solution from a constant pressure dropping funnel, and react at 65°C for 30 minutes under vigorous stirring.

[0052] After 30 minutes, under the protection of inert gas argon, acetone solution (2g hexafluorobutyl acrylate + 50g acetone solvent) was added dropwise to the above reaction solution for 1.0 hour, and then heated to 70°C for aging 6.0 hours of reaction.

[0053] After the reaction is finished, cool to room temperature, use a centrifuge to separate the solid and liquid from the abo...

Embodiment 2

[0057] Under the protection of inert gas argon, add 10g FLQT-5 aluminum powder, 1.0g polyvinylpyrrolidone, 1.0g methacrylic acid, 300ml ethanol solvent into a 2L three-neck flask equipped with a reflux condenser and a constant pressure dropping funnel, and ultrasonically disperse Aluminum powder is uniformly dispersed in alcohol solvent. Heat the above reaction solution to 70°C under vigorous stirring; slowly add the toluene solution (0.5g ABVN+20g toluene solvent) into the above reaction solution from a constant pressure dropping funnel, and react at 70°C for 30 minutes under vigorous stirring.

[0058] After 30 minutes, under the protection of the inert gas argon, a butanone solution (2g hexafluorobutyl acrylate+2g dodecafluoroheptyl acrylate+50g butanone solvent) was added dropwise to the above reaction solution, and the dropping time was 1.5 hours, and then the temperature was raised to 75° C. and aged for 6.0 hours.

[0059] After the reaction, cool to room temperature, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com