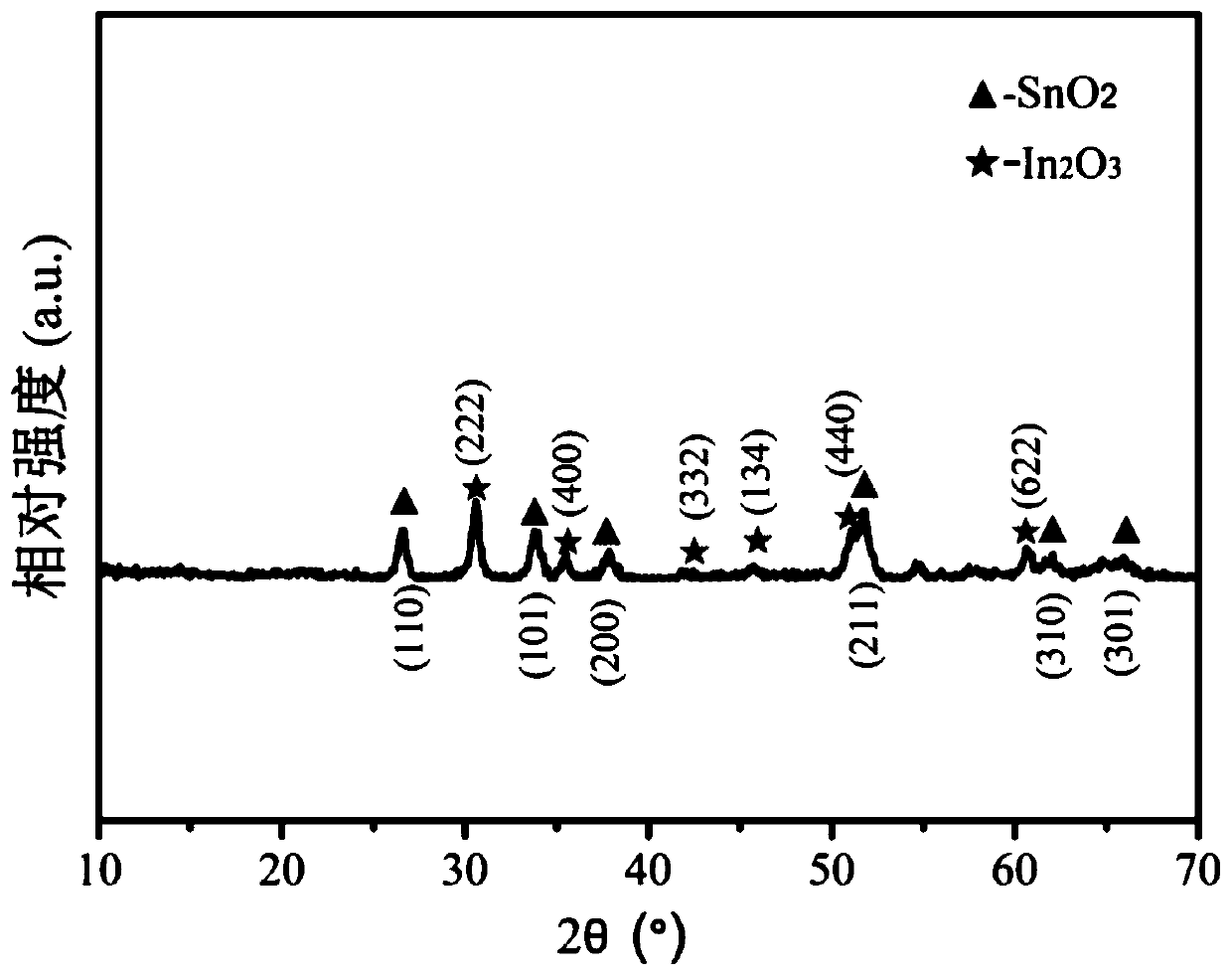

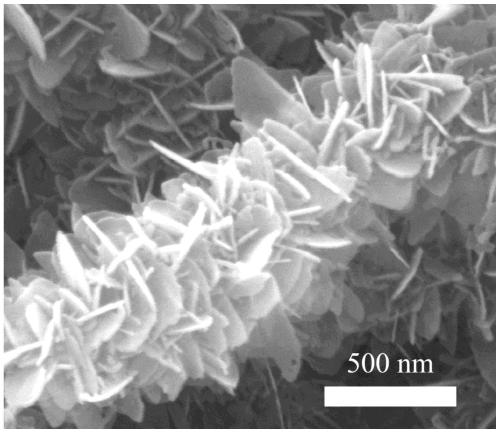

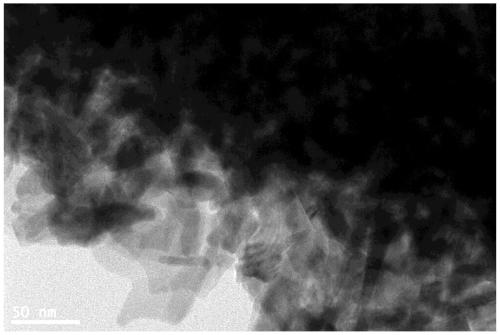

Three-dimensional In2O3/SnO2 core-shell nanocomposite for detecting formaldehyde gas and gas sensor prepared therefrom

A nanocomposite material and gas sensor technology, applied in the field of semiconductor nanomaterials, can solve the problems of insufficient sensitivity of formaldehyde gas, insufficient detection limit, high working temperature, etc., to achieve improved sensitivity and selectivity, low cost and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of three-dimensional In 2 o 3 / SnO 2 Core-shell nanocomposite material, its specific steps are as follows:

[0034] (1) with In(NO 3 ) 3 4.5H 2 O is the raw material, take 0.8gIn(NO 3 ) 3 4.5H 2 Dissolve O in a beaker containing a mixed solution of 4mL DMF and 6mL ethanol, add a magnet and place it on a magnetic stirrer to stir for 1h. After the solution becomes clear and transparent, slowly add 1gPVP and continue stirring for 12h to make it a clear and transparent viscous liquid . After completion, collect it into a 10mL syringe for use.

[0035](2) Put the syringe with the above-mentioned solution into the electrospinning machine, and set the relevant parameters as follows: the temperature inside the spinning machine is 45°C, the relative humidity is 20%, the voltage of the collecting plate and the needle tip of the syringe is adjusted to 18kV, The distance between the collection plate and the syringe needle was set at 15 cm. After the electrosp...

Embodiment 2

[0044] Preparation of three-dimensional In 2 o 3 / SnO 2 Core-shell nanocomposite material, its specific steps are as follows:

[0045] (1) With embodiment 1.

[0046] (2) With embodiment 1.

[0047] (3) 100mgIn 2 o 3 Add nanofibers to the above solution, and at the same time transfer the solution in the beaker to a 180mL reactor and place it in an oven at 180°C for hydrothermal reaction for 6 hours. After the reaction is over, wash the obtained precipitate three times with water and ethanol respectively. , and placed in a 60°C drying oven to dry overnight. After drying, the samples were collected and calcined at a heating rate of 2°C / min to 500°C and kept at a temperature of 2h.

[0048] From the above three-dimensional In 2 o 3 / SnO 2 The specific steps for preparing the gas sensor from the core-shell nanocomposite are the same as in Example 1.

Embodiment 3

[0050] Preparation of three-dimensional In 2 o 3 / SnO 2 Core-shell nanocomposite material, its specific steps are as follows:

[0051] (1) With embodiment 1.

[0052] (2) With embodiment 1.

[0053] (3) 100mgIn 2 o 3 Add nanofibers to the above solution, and at the same time transfer the solution in the beaker to a 180mL reactor and place it in a 180°C oven for hydrothermal reaction for 18 hours. After the reaction is over, wash the obtained precipitate three times with water and ethanol respectively. , and placed in a 60°C drying oven for overnight drying. After drying, the samples were collected and calcined at a heating rate of 2°C / min to 500°C and kept for 2 hours to obtain the product.

[0054] From the above three-dimensional In 2 o 3 / SnO 2 The specific steps for preparing the gas sensor from the core-shell nanocomposite are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com