Flame-retardant PVC cable material and production method thereof

A technology of cable material and PVC resin, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems affecting the flame retardant effect and mechanical properties of polymer materials, and achieve the improvement of flame retardant and smoke suppression efficiency and mechanical properties, The raw materials are easy to obtain, and the effect of heat and oxygen insulation is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

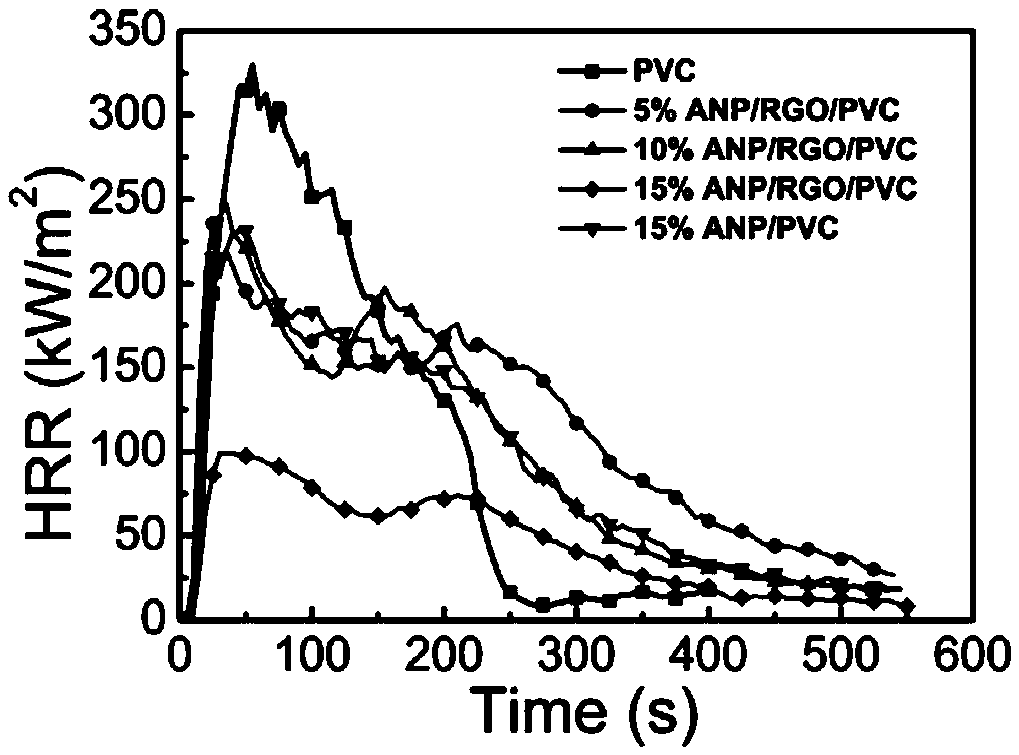

[0027] (1) Dry 100 g of PVC resin and 5 g of ANP / RGO in a blast oven at 100 °C for 1 hour.

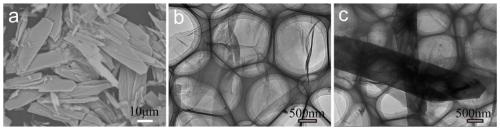

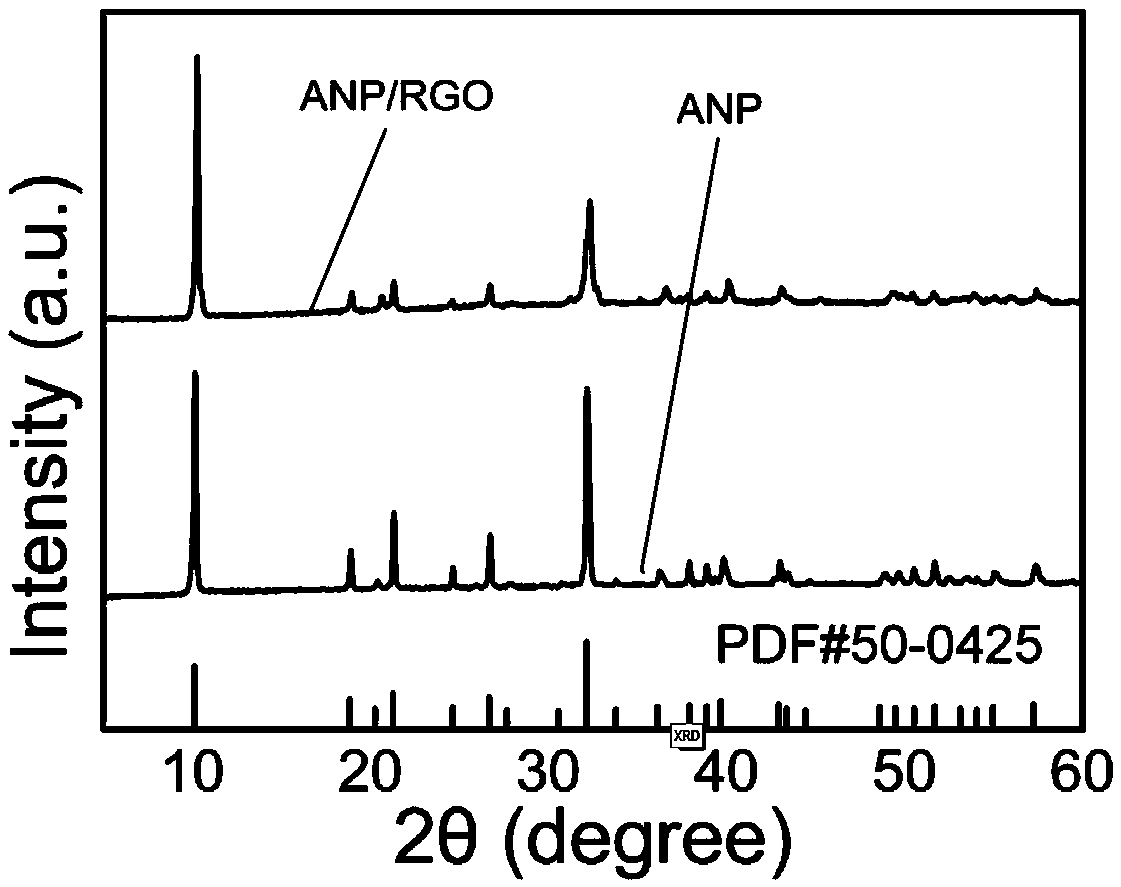

[0028] The invention obtains the hybrid material (ANP / RGO) of ammonium nickel phosphate and reduced graphene oxide through a one-step solvothermal method. The specific experimental steps are as follows: First, 50 mL of ethylene glycol was added to 50 mL of concentrated ammonia water and stirred mechanically for 10 min to form a uniform solution. Then, ultrasonically exfoliated graphene oxide (GO) (50 mL, 0.08 g), sodium dodecylsulfonate (10 mL, 0.75 g), anhydrous potassium carbonate (25 mL, 1 M), dipotassium hydrogen phosphate (37.5 mL, 1 M) and nickel nitrate hexahydrate (25 mL, 1 M) were slowly added to the above homogeneous solution one by one, and kept stirring for 1 h until the mixed solution turned bright blue . Subsequently, the mixed solution was transferred to a 500 mL reactor and heated at 170 °C for 12 h. Finally, the reactor was cooled to room temperature, the precipitat...

Embodiment 2

[0041] Same as Example 1, except that the flame retardant is 10 g of ANP / RGO, that is, 100 g of PVC resin and 10 g of ANP / RGO in step (1).

Embodiment 3

[0043] Same as Example 1, except that the flame retardant is 15 g of ANP / RGO, that is, 100 g of PVC resin and 15 g of ANP / RGO in step (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com