A kind of preparation method of low extraction, high temperature resistant insulating polyester film

A technology of polyester film and high temperature resistance, which is applied in the field of polyester manufacturing, can solve the problems of affecting inhibition performance, inapplicability, and adverse effects on durability, and achieve the goal of reducing the content of oligomers, reducing side reactions, and enhancing stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

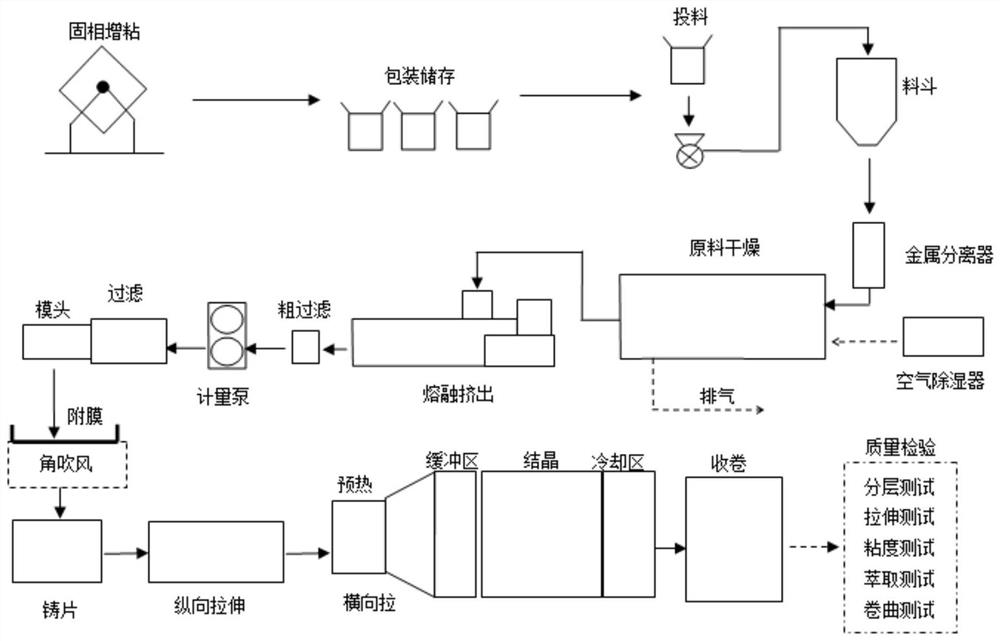

Method used

Image

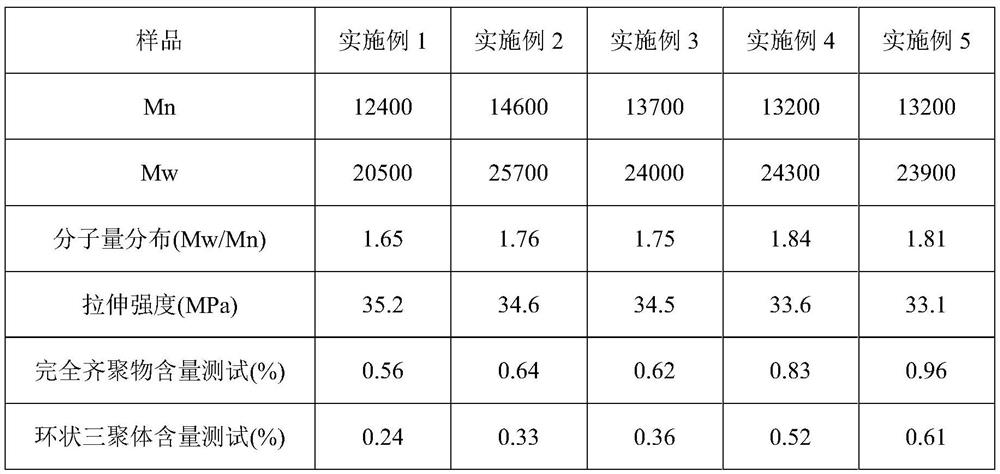

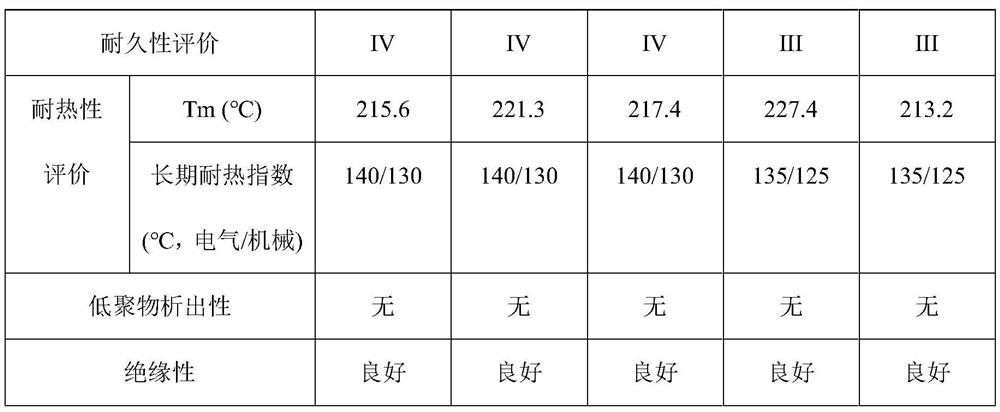

Examples

preparation example 1

[0042] In a 500mL three-necked flask equipped with a mechanical stirrer, a thermometer and a condenser, add 13.2g tetraisopropyl titanate and 85.8g bis(diphenylphosphinoethyl)amine and 120.4g isopropanol solvent respectively, Under the protection of nitrogen, stir evenly, control the temperature at 90±5° C., react for 6 hours, cool slowly, and dry in vacuum to obtain the complex formed by the titanium and bis(diphenylphosphinoethyl)amine.

preparation example 2

[0044] In a 500mL three-necked flask equipped with a mechanical stirrer, a thermometer and a condenser, add 16.6g tetra-tert-butyl titanate and 96.2g bis(diphenylphosphinoethyl)amine and 146.1g isopropanol solvent respectively, Under the protection of nitrogen, stir evenly, control the temperature at 90±5° C., react for 6 hours, cool slowly, and dry in vacuum to obtain the complex formed by the titanium and bis(diphenylphosphinoethyl)amine.

Embodiment 1

[0047] (1) Preparation of polyester: according to parts by mass, 100 parts of terephthalic acid (TPA), 48.2 parts of ethylene glycol (EG), 6.3 parts of neopentyl glycol, 0.15 parts of antioxidant 1010, 0.1 part of triphosphate The phenyl ester is fully mixed, and the esterification reaction is carried out under the conditions of a nitrogen atmosphere, a reaction temperature of 260°C, and a pressurized pressure of 0.2 MPa. When the amount of water distilled out in the esterification reaction reaches more than 90% of the theoretical value, the reaction ends Obtain esterification product; Add the complex compound of 0.03 part of bis (diphenylphosphine ethyl) amine-titanium afterwards and carry out polycondensation reaction as catalyst, polycondensation is divided into two stages of prepolymerization and final polycondensation, the reaction of the prepolymerization stage The conditions are under a vacuum condition of 15kPa, the reaction temperature is 270°C, and the reaction is 2h;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com