A method for directly preparing xylitol from hemicellulose

A technology for hemicellulose and xylitol, applied in chemical instruments and methods, preparation of hydroxyl compounds, catalyst activation/preparation, etc., can solve the problems of low yield of xylitol, easily corroded equipment, difficult to recover, etc. Simple method, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the magnetic solid acid catalyst in following embodiment comprises:

[0025] (1) Roast HZSM-5 in a muffle furnace at 500°C for 4 hours, grind it through a 100-mesh sieve, then immerse it in a 1.0mol / L phosphoric acid solution with deionized water as the solvent for 2 hours, and then dry it at 105-110°C 12-18h, put it in a muffle furnace at 500°C and bake for 4h again to obtain the carrier;

[0026] (2) Dissolve the precursor of the active metal in deionized water and pour it into the above-mentioned carrier, soak it for 12-15 hours, then dry it in a blast drying oven at 105-112°C for 12-18 hours, and then heat it at 500°C Roast in a furnace for 3-5 hours, grind through a 100-mesh sieve, pass hydrogen into a reduction furnace at 500°C for reduction for 3-5 hours, and obtain the magnetic solid acid catalyst. The above-mentioned active metal is composed of Ni, Fe and Zr , or composed of Ni and Fe.

Embodiment 1-5

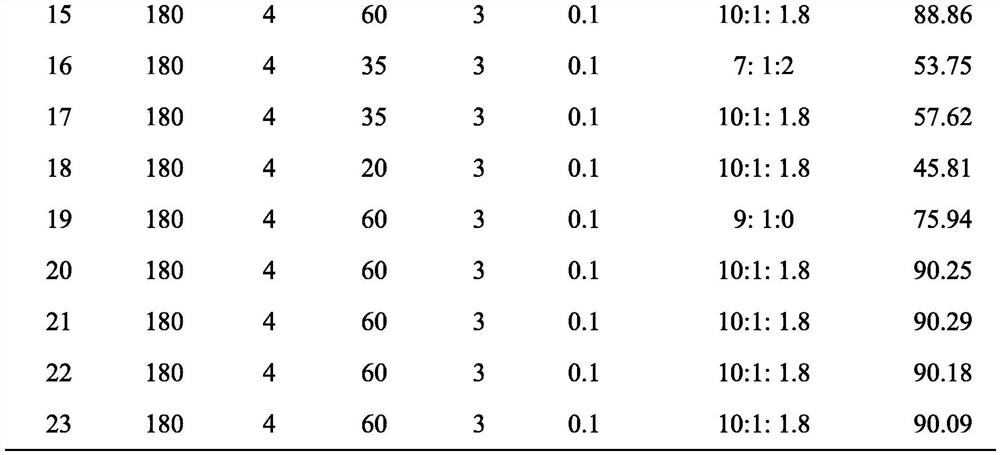

[0029] 0.5g corncob hemicellulose, 50g deionized water, 0.1g magnetic solid acid catalyst (the total load of active metal is 60wt%, and the molar ratio of active metal Ni, Fe, Zr is 10:1:1.8) joins in In a 100mL autoclave, replace the air in the ax with hydrogen, pass in 3MPa hydrogen, seal the autoclave, stir at 600rpm, heat to 180°C and keep it for 1-5h, finish the reaction and cool at room temperature, magnetically separate the solid and liquid, and take the supernatant solution, prepare xylitol standard solution, use high performance liquid chromatography to carry out qualitative and quantitative detection, and the detection results are listed in Table 1, serial number is 1-5.

Embodiment 6-8

[0031] 0.5g corncob hemicellulose, 50g deionized water, 0.1g magnetic solid acid catalyst (the total load of active metal is 60wt%, and the molar ratio of active metal Ni, Fe, Zr is 10:1:1.8) joins in In a 100mL autoclave, replace the air in the ax with hydrogen, pass in 3MPa hydrogen, seal the autoclave, stir at a speed of 600rpm, heat to 170-200°C and keep for 4h, finish the reaction and cool at room temperature, magnetically separate the solid and liquid, and take the supernatant solution, prepare xylitol standard solution, use high performance liquid chromatography to carry out qualitative and quantitative detection, the detection results are listed in Table 1, serial number is 6-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com