Method for performing surface coating and gradient doping integrated double-modification on LNMO anode material by using one-step method

A cathode material and surface coating technology, which is applied in the field of preparation and modification of cathode materials for new energy lithium ion batteries, can solve problems such as unfavorable industrial application, influence of bulk phase structure, poor repeatability, etc., and improve interface compatibility. , the effect of alleviating structural degradation and inhibiting the occurrence of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

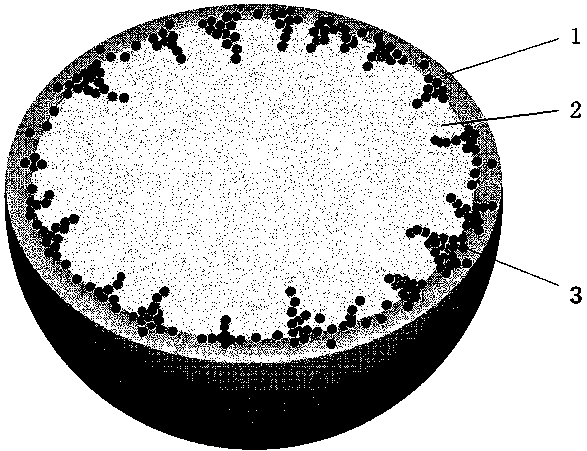

[0035] "One-step" preparation of Li 3 V 2 (PO 4 ) 3 (LVPO) surface modified LNMO material, the steps are as follows:

[0036] Dissolve a certain amount of lithium acetate, vanadium pentoxide, ammonium dihydrogen phosphate and citric acid in deionized water according to the ratio of 3:2:3:3, mix and stir for 3 hours, fully dissolve the mixed solution and add it dropwise Into the aqueous solution containing 0.2g LNMO cathode material, continue to mix and stir for 8h; stir and evaporate the mixed solution at 80°C for 8h to form a sol, and dry at 120°C for 24h to obtain a xerogel; grind the above xerogel thoroughly and put In a tube furnace, calcined at 400 °C for 6 h in an argon (Ar) atmosphere, then naturally cooled to room temperature, cleaned, filtered, and dried to obtain Li 3 V 2 (PO 4 ) 3 (LVPO) surface-modified LNMO materials.

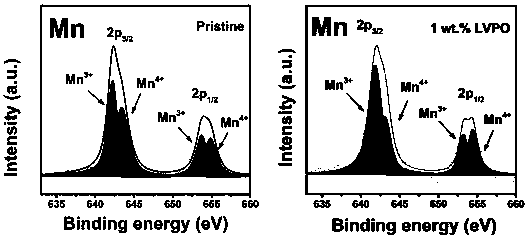

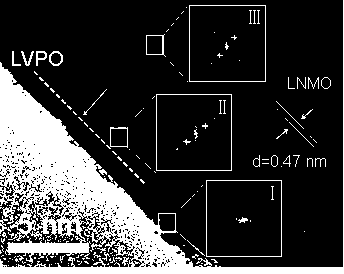

[0037] as attached figure 1 Shown are the XRD test and refinement results of the original spinel structure LNMO and the "one-step" LVPO...

Embodiment 2

[0053] "One-step" preparation of Li 3 VO 4 Surface coating and V surface gradient doping double modified LNMO material, the steps are as follows:

[0054] (1) Dissolve a certain amount of lithium acetate, vanadium pentoxide and citric acid in deionized water according to the ratio of 3:1:2, dissolve them and add dropwise to the aqueous solution in which 0.2g of LNMO cathode material is dispersed In, then mixed and stirred for 8h;

[0055](2) The above mixed solution was heated up to 80°C, stirred and evaporated, and then dried at 120°C for 24 hours to obtain a xerogel;

[0056] (3) Put the above dry gel into a crucible after being fully ground, calcined in a tube furnace at 500°C for 6h under an argon atmosphere, then naturally cooled to room temperature, cleaned, filtered, and dried to obtain Li 3 VO 4 Surface coating and V surface gradient doping double modified LNMO materials.

Embodiment 3

[0058] "One-step" preparation of Li 2 SiO 3 Surface cladding and Si surface gradient doping double modified LNMO material, the steps are as follows:

[0059] (1) Dissolve a certain amount of lithium hydroxide, tetraethyl orthosilicate and citric acid in deionized water according to the ratio of 2:1:1.5, dissolve them and add them dropwise to the dispersed 0.2g LNMO cathode material In the aqueous solution, adjust the pH of the solution to ~7, and then mix and stir for 5h;

[0060] (2) The above mixed solution was heated up to 80°C, stirred and evaporated, and then dried at 120°C for 24 hours to obtain a xerogel;

[0061] (3) Put the above dry gel into a crucible after being fully ground, and calcined in a tube furnace at 500°C for 5 hours under an argon atmosphere, then naturally cooled to room temperature, cleaned, filtered, and dried to obtain Li 2 SiO 3 Surface coating and Si surface gradient doping double modified LNMO materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com