A kind of preparation method of highly active iron-carbon micro-electrolytic filler

A technology of iron-carbon micro-electrolysis and iron-carbon filler, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of low current density, micro-electrolysis failure, iron Uneven distribution of carbon and other problems, to achieve the effect of increasing the electrochemical corrosion rate and current density, improving the efficiency of electron transfer, and improving the efficiency of internal electrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

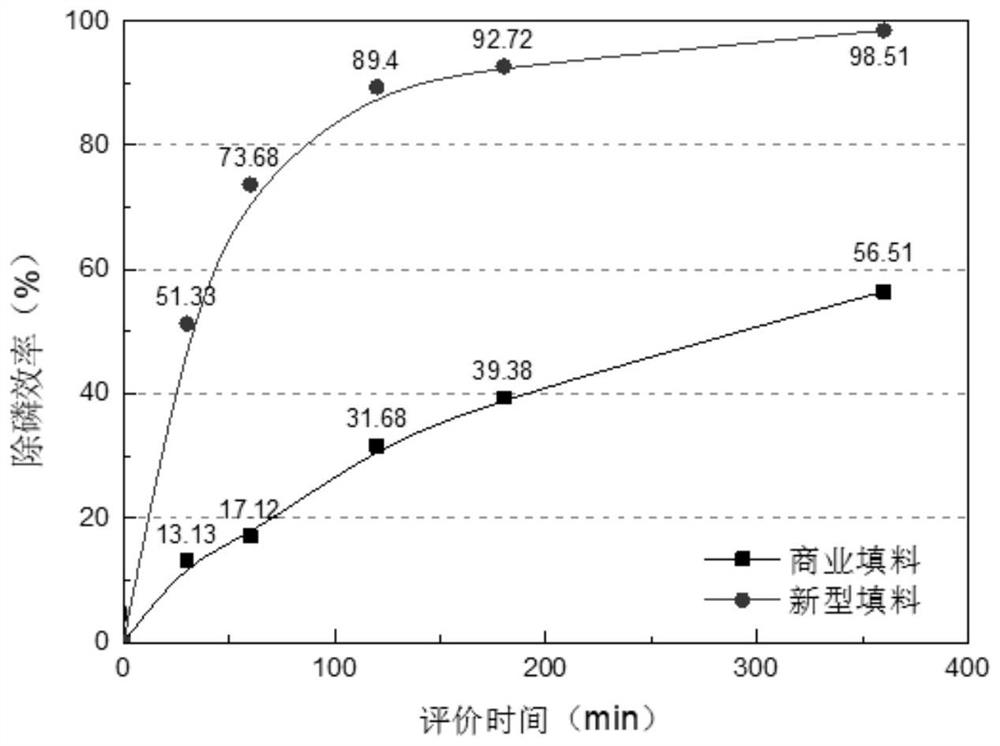

Image

Examples

preparation example Construction

[0028] The preparation method of the highly active iron-carbon micro-electrolytic filler comprises the following steps:

[0029] (1) The above-mentioned iron-based materials and carbon-based material precursors (high-carbon pyrolysis oil of organic solid waste such as coal, biomass, garbage, plastics, sludge) are carried out at a mass ratio of 1:0.01 to 1:5. Mix well, carry out ultrasonic strengthening treatment at room temperature -90°C for 10-60 minutes, and keep stirring and mixing, and perform homogenization treatment to obtain the mixed material;

[0030] (2) Carbonize the homogenized mixed material in an anaerobic atmosphere at 500-1200°C, in which the heating rate of the material is controlled at 0.1-99°C / min, the residence time is 0-120min, and then cooled to room temperature. Obtain carbides of iron-based materials;

[0031] (3) Mechanically mix the above-mentioned iron-based material carbide and binder in a predetermined ratio, control the mass fraction of the binde...

Embodiment 1

[0034] A highly active iron-carbon micro-electrolytic filler is composed of 50% iron ore (47% TFe), 20% biomass pyrolysis oil high-temperature carbonized solid carbon and 30% clay, which are homogenized, carbonized, and mechanically formed in sequence Treatment and high temperature sintering treatment.

[0035] The preparation method of the highly active iron-carbon micro-electrolytic filler specifically includes:

[0036] (1) Fully mix the above-mentioned iron ore and biomass pyrolysis oil according to a mass ratio of 1:5, perform ultrasonic strengthening treatment at 60°C for 20 minutes, and continuously stir and mix, and perform homogenization treatment to obtain a mixed material;

[0037] (2) Carbonize the homogenized mixed material in an anaerobic atmosphere at 600°C, in which the heating rate of the material is controlled at 20°C / min, the residence time is 0min, and then cooled to room temperature to obtain the iron-carbon filler precursor ;

[0038] (3) Mechanically m...

Embodiment 2

[0041] A high-activity iron-carbon micro-electrolytic filler is composed of 90% sponge iron (86% TFe), 2.1% coal pyrolysis oil high-temperature carbonized solid carbon and 7.9% clay, which are subjected to homogenization treatment, carbonization treatment, mechanical forming treatment and Obtained by high temperature sintering treatment.

[0042] The preparation method of the highly active iron-carbon micro-electrolytic filler specifically includes:

[0043] (1) Fully mix the sponge iron and coal pyrolysis oil at a mass ratio of 1:0.3, perform ultrasonic strengthening treatment at 45°C for 30 minutes, and continuously stir and mix, and perform homogenization treatment to obtain the mixed material;

[0044] (2) Carbonize the homogenized mixed material in an anaerobic atmosphere at 950°C, in which the heating rate of the material is controlled at 50°C / min, the residence time is 30min, and then cooled to room temperature to obtain the iron-carbon filler precursor ;

[0045] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com