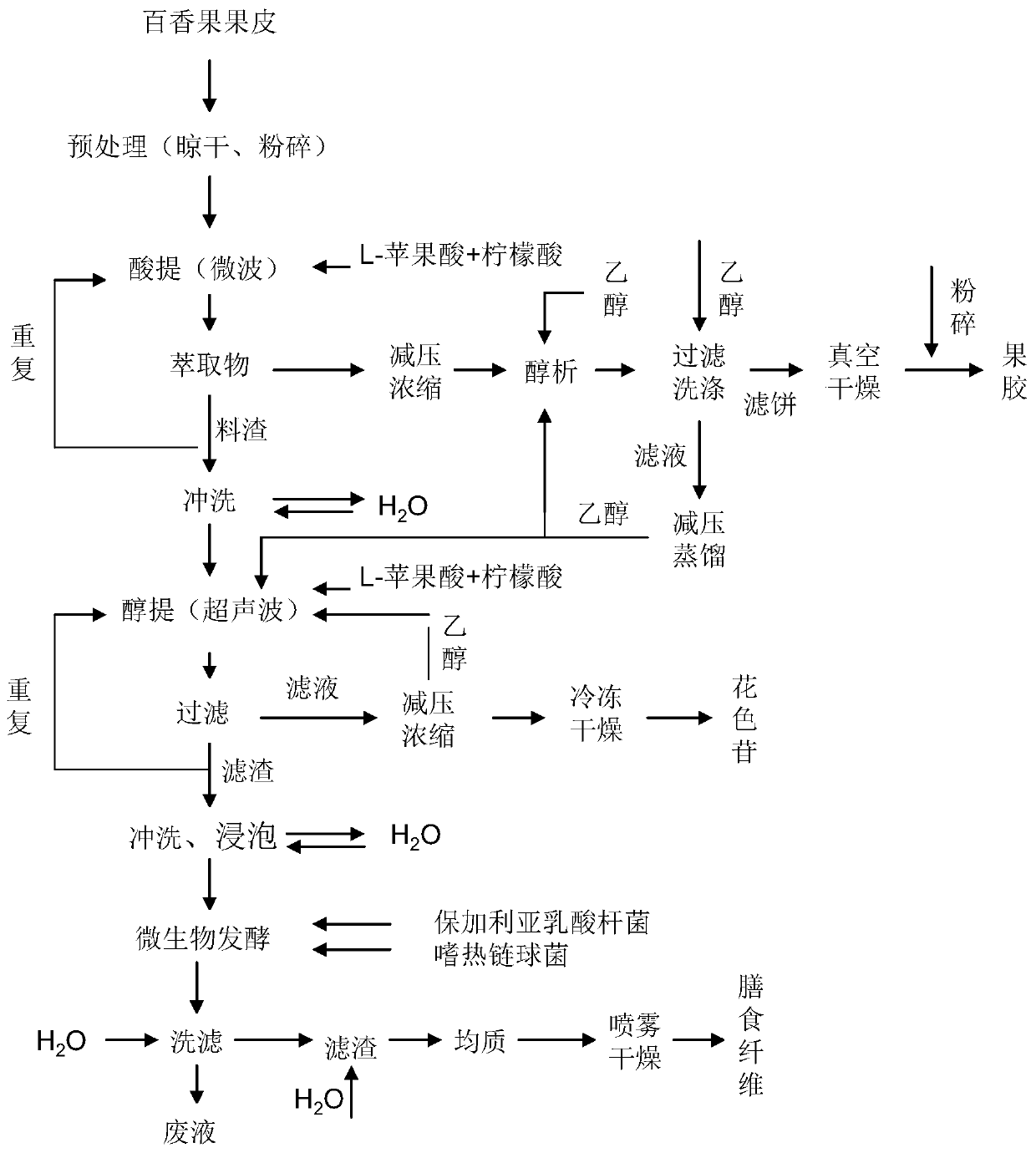

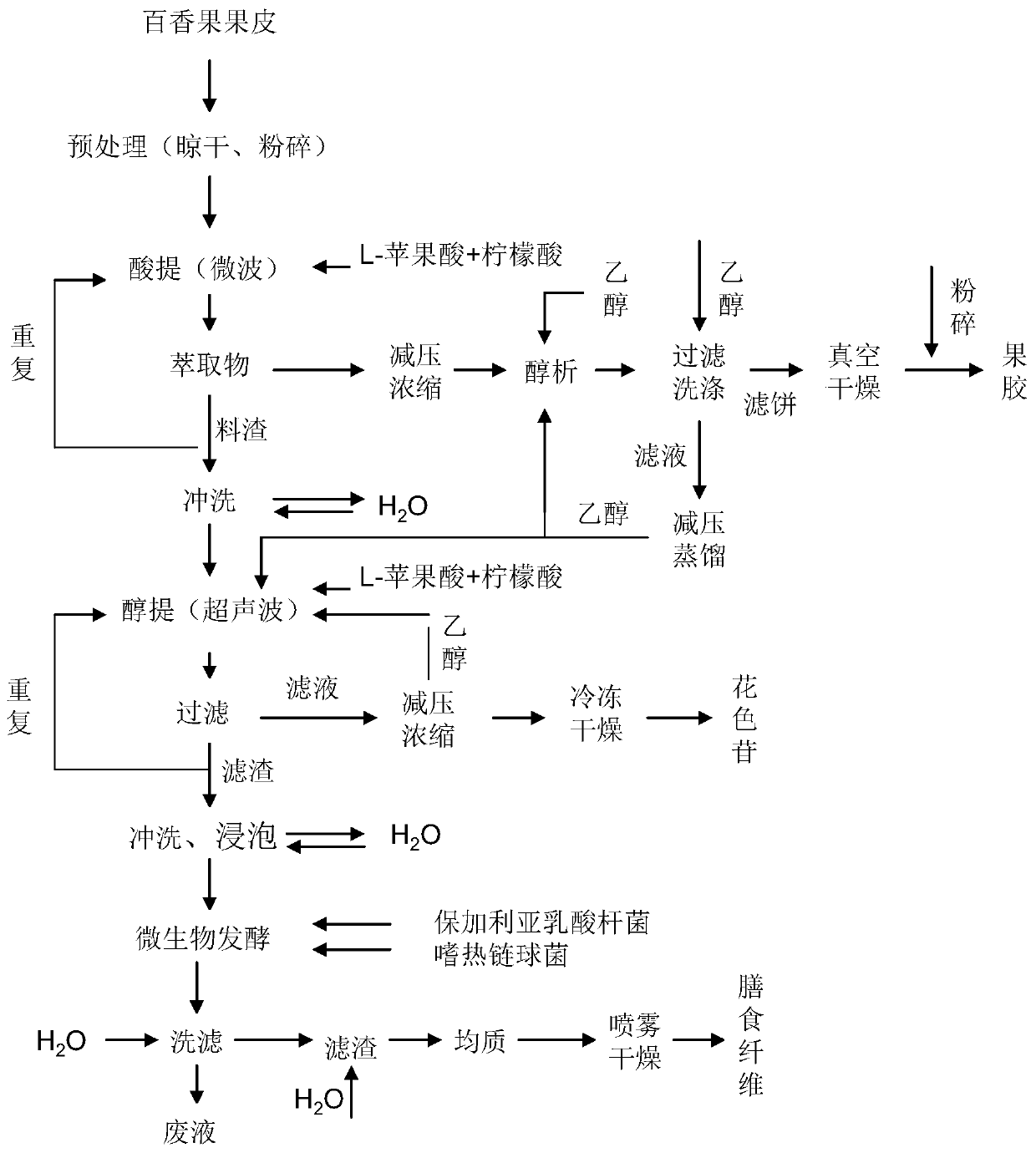

Co-production extraction process of pectin, anthocyanin and dietary fibers in passion fruit peel

A dietary fiber, co-production extraction technology, applied in biochemical equipment and methods, microorganisms, organic chemistry, etc., can solve the problems of ineffective products, many operation steps, high energy consumption, etc., to increase farmers' income, reduce Environmental pollution, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A co-production extraction process of pectin, anthocyanin and dietary fiber in passion fruit peel:

[0029] 1) Extraction of pectin from the citronella peel: dry the collected passion fruit rind outdoors at room temperature, crush it, pass it through a 100-mesh sieve, and set aside; take 100g of the sieved rind, add an appropriate amount of water, and configure it as a material For a solution with a liquid ratio of 1:50, use L-malic acid and citric acid to adjust the pH of the solution to 1.0, and perform microwave-assisted extraction with a microwave power of 350W and a microwave time of 10.0min; separate the solution and residue after microwave extraction, and then microwave the residue Repeat the extraction once; collect all the slag for the next step of anthocyanin extraction, combine the 2 extraction solutions, and then concentrate the extraction solution under reduced pressure, 90% ethanol alcohol analysis, collect the alcohol analysis washings, vacuum dry, crush, ...

Embodiment 2

[0034] A co-production extraction process of pectin, anthocyanin and dietary fiber in passion fruit peel:

[0035] 1) Extraction of pectin from the fruit peel: dry the collected passion fruit peel outdoors at room temperature, crush it, pass through a 50-mesh sieve, and set aside; take 100g of the sieved peel, add an appropriate amount of water, and prepare it as a feed liquid Ratio 1:60 solution, use L-malic acid and citric acid to adjust the pH of the solution to 2.5, carry out microwave-assisted extraction, microwave power 400W, microwave time 15.0min; separate the solution and material residue after microwave extraction, and microwave the material residue again Extract 1 time; collect all the residues for the next step of anthocyanin extraction, combine the 2 extraction solutions, and then concentrate the extraction solution under reduced pressure, 95% ethanol alcohol analysis, collect the washings after alcohol analysis, vacuum dry, and crush to obtain the fruit Glue 12.3...

Embodiment 3

[0040] A co-production extraction process of pectin, anthocyanin and dietary fiber in passion fruit peel:

[0041] 1) Extraction of pectin from the fruit peel: dry the collected passion fruit peel outdoors at room temperature, crush it, pass through a 50-mesh sieve, and set aside; take 100g of the sieved peel, add an appropriate amount of water, and prepare it as a feed liquid For a solution with a ratio of 1:35, use L-malic acid and citric acid to adjust the pH of the solution to 1.0, and perform microwave-assisted extraction with a microwave power of 300W and a microwave time of 20.0min; separate the solution and residue after microwave extraction, and repeat the microwave-assisted extraction of the residue Extract 1 time; collect all the slag for the next step of anthocyanin extraction, combine the 2 extraction solutions, and then concentrate the extraction solution under reduced pressure, 90% ethanol alcohol analysis, collect the washings after alcohol analysis, vacuum dry,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com