Phase change material microcapsule coating method and application

A technology of phase change materials and microcapsules, which is applied in the preparation of microcapsule preparations and microspheres, can solve the problems of poor biocompatibility, high cost, and cumbersome steps, and achieve the effects of low cost, easy method, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The specific embodiment of the Pickering emulsion coated phase change material paraffin prepared with cellulose nanocrystal as emulsifier is as follows:

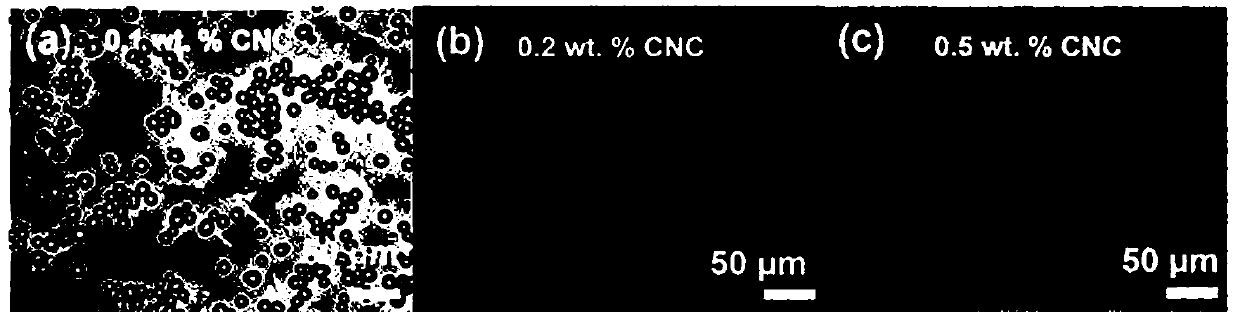

[0030] 1) Disperse the cellulose nanocrystals (CNC) in deionized water by homogenizing with a homogenizer or ultrasonically pulverizing with a cell pulverizer to prepare a water suspension with a concentration mass fraction of 0.1%, 0.2% or 0.5%, and then add A certain amount of salt, such as sodium chloride, etc., the concentration of the salt is 0.1 to 1.5wt.%. The dispersion is used as the aqueous phase of the Pickering emulsion;

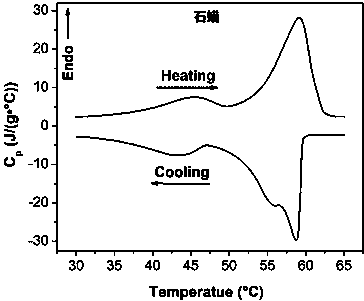

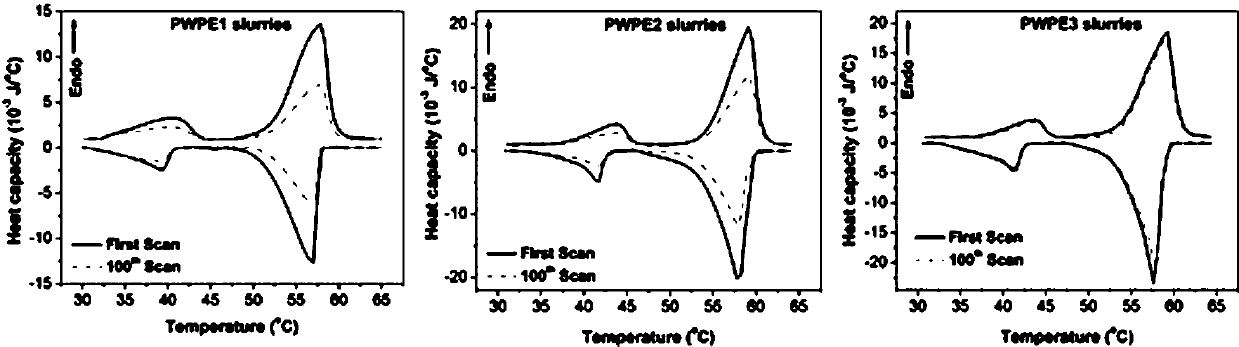

[0031] 2) The oil phase of the Pickering emulsion was 12 grams of paraffin, and then 40 grams of the above-mentioned cellulose nanocrystal dispersion was added as the water phase. The melting point of paraffin wax used here is 58 to 62 ° C, and the differential scanning calorimetry (DSC) curve of this paraffin wax is as attached figure 1 shown. According to this DSC curve, the melting ...

Embodiment 2

[0040] Taking the Pickering emulsion stabilized by cellulose nanocrystals as a template and adopting Pickering emulsion polymerization to prepare specific examples of polystyrene-coated microcapsules are as follows:

[0041] 1) Disperse the cellulose nanocrystals in deionized water by homogenizing with a homogenizer or ultrasonically pulverizing with a cell pulverizer to prepare a water suspension with a concentration mass fraction of 0.5%, and use this dispersion as the water of the Pickering emulsion Mutually;

[0042] 2) The oil phase of the Pickering emulsion is a mixture of 1.8 gram styrene, 0.2 gram divinylbenzene and 10 gram paraffin, then add the dispersion liquid of 38 gram above-mentioned cellulose nanocrystals as water phase;

[0043] 3) The mixture was heated to 70° C., and nitrogen gas was introduced for 30 minutes, and then 20 mg of azobisisobutyronitrile was added;

[0044] 4) Under the protection of nitrogen, the above-mentioned mixed solution was ultrasonical...

Embodiment 3

[0055] Taking the Pickering emulsion stabilized by cellulose nanocrystals as a template and adopting Pickering emulsion polymerization to prepare polymethyl methacrylate (PMMA) coated microcapsules The specific examples are as follows:

[0056] 1) Disperse the cellulose nanocrystals in deionized water by homogenizing with a homogenizer or ultrasonically pulverizing with a cell pulverizer to prepare a water suspension with a concentration mass fraction of 0.5%, and use this dispersion as the water of the Pickering emulsion Mutually;

[0057] 2) The oil phase of the Pickering emulsion is a mixture of 1.8 gram methyl methacrylate, 0.2 gram divinylbenzene and 10 gram paraffin, then add the dispersion liquid of 38 gram above-mentioned cellulose nanocrystals as water phase;

[0058] 3) The mixture was heated to 70° C., and nitrogen gas was introduced for 30 minutes, and then 20 mg of azobisisobutyronitrile was added;

[0059] 4) Under the protection of nitrogen, the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com