Ceramic material for LED lamp and preparation method thereof

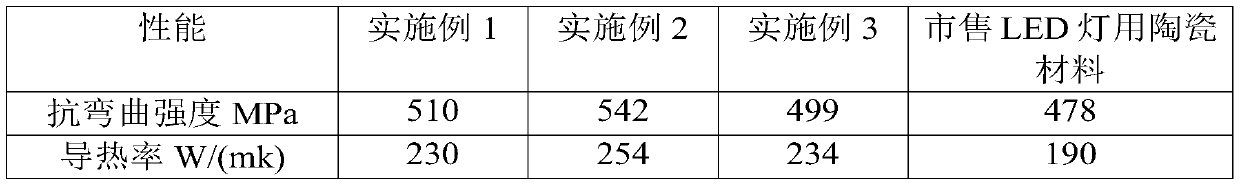

A technology of ceramic materials and LED lamps, which is applied in the field of ceramic materials, can solve the problems of low bending strength and poor thermal conductivity, and achieve the effects of high bending strength, improved quality, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of ceramic material for LED lamp

[0030] The raw materials and parts by weight for preparing ceramic materials for LED lights are: 30kg of aluminum nitride, 15kg of aluminum oxide, 2kg of talc, 15kg of silicon carbide, 12kg of zinc white powder, 8kg of zirconium diboride, 5kg of titanium diboride, and 3kg of nano-magnesium oxide , bentonite 11kg, modified kaolin 14kg, carbon fiber 5kg, binder 3kg, defoamer 7kg.

[0031] The preparation method of modified kaolin is as follows: impregnate kaolin powder with silane coupling agent, then put it into a low-temperature microwave drying oven at 850 ° C for 1 hour, cool to room temperature, and obtain modified kaolin after grinding. The mixture of kaolin powder and silane coupling agent The weight ratio is 3:1.

[0032] The preparation method of ceramic material for LED lamp, the steps are as follows:

[0033] Step S1, placing the aluminum nitride, aluminum oxide, and silicon carbide in the parts by weight in a grindin...

Embodiment 2

[0038] A kind of ceramic material for LED lamp

[0039] The raw materials and parts by weight for preparing ceramic materials for LED lights are: aluminum nitride 58kg, aluminum oxide 24kg, talc 9kg, silicon carbide 28kg, zinc white powder 14kg, zirconium diboride 11kg, titanium diboride 10kg, nano-magnesium oxide 6kg , bentonite 16kg, modified kaolin 19kg, carbon fiber 8kg, binder 35kg, defoamer 8kg.

[0040]The preparation method of modified kaolin is as follows: impregnate kaolin powder with silane coupling agent, then put it into a low-temperature microwave drying oven at 900 ° C for 2 hours, cool to room temperature, and obtain modified kaolin after grinding. The mixture of kaolin powder and silane coupling agent The weight ratio is 3:2.

[0041] The preparation method of ceramic material for LED lamp, the steps are as follows:

[0042] Step S1, placing the aluminum nitride, aluminum oxide, and silicon carbide in the parts by weight in a grinding machine, grinding for t...

Embodiment 3

[0047] A kind of ceramic material for LED lamp

[0048] The raw materials and parts by weight for preparing ceramic materials for LED lamps are: aluminum nitride 43kg, aluminum oxide 19kg, talc 7kg, silicon carbide 21kg, zinc white powder 13kg, zirconium diboride 9kg, titanium diboride 9kg, nano-magnesium oxide 3.6 kg, bentonite 14kg, modified kaolin 17kg, carbon fiber 5.8kg, binder 3.5kg, defoamer 7.8kg.

[0049] The preparation method of modified kaolin is as follows: impregnate kaolin powder with silane coupling agent, then put it into a low-temperature microwave drying oven at 890 ° C for 1.2 hours, cool to room temperature, and grind to obtain modified kaolin, kaolin powder and silane coupling agent The weight ratio is 3:1.5.

[0050] The preparation method of ceramic material for LED lamp, the steps are as follows:

[0051] Step S1, placing the aluminum nitride, aluminum oxide, and silicon carbide in the parts by weight in a grinding machine, grinding for the first tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com